- Table of Contents

-

- H3C CR16000-F Router Series Installation Guide-5W107

- 00-Preface

- 01-Chapter 1 Preparing for Installation

- 02-Chapter 2 Installing the Router

- 03-Chapter 3 Installing FRUs

- 04-Chapter 4 Connecting Your Router to the Network

- 05-Chapter 5 Troubleshooting

- 06-Chapter 6 Replacement Procedures

- 07-Appendix A Engineering Labels for Cables and Devices

- 08-Appendix B Cabling Recommendations

- 09-Appendix C Repackaging the Router

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 08-Appendix B Cabling Recommendations | 3.69 MB |

Contents

Appendix B Cable management

Label cables before you route or bundle them. For more information about labeling cables, see "Appendix A Engineering labels for cables."

General cabling requirements

Minimum curvature radius of cables

· The curvature radius of an attached power cord, communication cable, or ribbon cable should be a minimum of five times of the cable’s outer diameter. If the cable is frequently bent, connected and removed, the curvature radius should be a minimum of seven times the cable's outer diameter.

· The curvature radius of an ordinary attached coaxial cable should be a minimum of seven times of the cable's outer diameter. If the coaxial cable is frequently bent, connected and removed, the curvature radius should be a minimum of 10 times of the cable's outer diameter.

· The curvature radius of a high-speed cable should be a minimum of five times of the cable's outer diameter. If the coaxial cable is frequently bent, connected and removed, the curvature radius should be a minimum of 10 times of the cable's outer diameter.

Minimum curvature radius of fibers

· When the fiber is wrapped up around the cabling plate, the diameter of the cabling plate should be a minimum of 25 times of the fiber's diameter.

· When the fiber is being moved, the curvature radius of the fiber should be a minimum of 20 times of the fiber's diameter.

· When the fiber is attached, the curvature radius of the fiber should be a minimum of 10 times of the fiber's diameter.

|

|

NOTE: The fiber's diameter refers to the outer diameter of the fiber jacket. Typically, the diameter of a single-core fiber is 0.9 mm (0.04 in), 2.0 mm (0.08 in), or 3.0 mm (0.12 in). |

Cable management guidelines

When you route and bundle up cables, follow these guidelines:

· Bind cables neatly for easy maintenance and expansion.

· The cable management brackets and cable routing slots, inside or outside the rack, are smooth and have no sharp edges or tips.

· Route different types of cables (for example, power cords and signal cables) separately. If they are close to one another, cross them over one another. If you route them in parallel, make sure the space between a power cord bundle and a signal cable bundle is equal to or greater than 30 mm (1.18 in).

· Use the correct ties to bind the cables. Do not bind cables with joined ties.

· The distances between cable ties must be three to four times of the cable diameter.

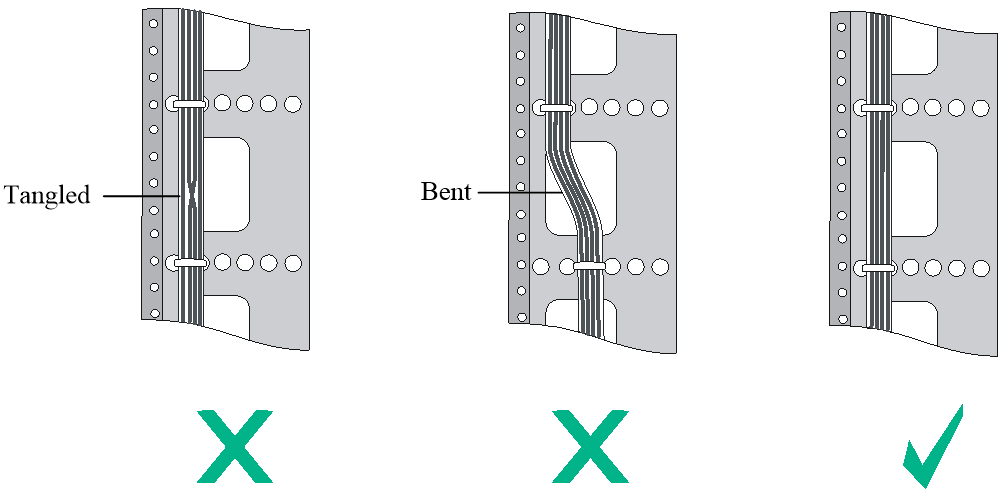

· Bind and route the cables neatly inside the rack, and make sure the cables are not kinked or bent. Do not tie cables or bundles in a knot.

Figure 1 Correct and incorrect cable binding

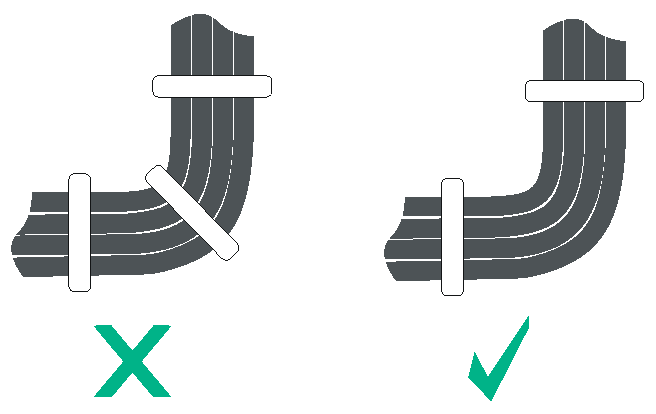

· When you bend cables, bind cables as shown in Figure 2. To avoid cable core break due to excessive stress, do not tie up the cables in the bending area. The cable bend radius at connectors must be a minimum of 5 times the cable diameter, and must be a minimum of 5 times the cable diameter away from the connectors.

· When you route cables through sharp sheet metal penetration points or along sharp edges of mechanical parts, use bushings or take any other action to protect the cables from being cut or abraded. The sheet metal penetration points must be smooth and fully rounded.

· When optical fibers are inserted into a protective tube, wrap tapes around the edges of the protective tube to protect optical fibers from being cut.

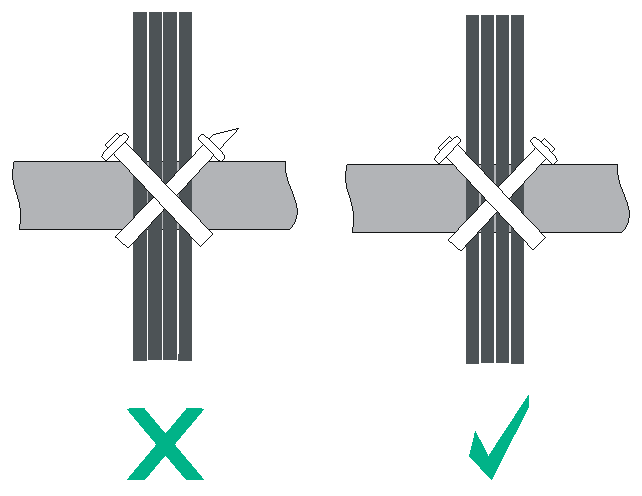

· After binding the cables, cut the excess from the ties, leaving no sharp or angular tips. See Figure 3.

Figure 3 Cutting the cable ties

· Route, bind, and attach excess cables for easy, safe maintenance activities and proper operations.

· Do not tie the power cords to the slide rails.

· When you connect a cable to an articulated part, for example, when you connect a grounding cable to a rack door, leave enough slack in cables and make sure they are not stressed from any movement of the part.

· Cables must be protected at points where they might rub or come in contact with sharp edges or heated areas. Use high temperature cables near heat sources.

· Fasten heavy or rigid power cords at the connectors to relief stress.

Cable management

The devices in the following figures are for illustration only.

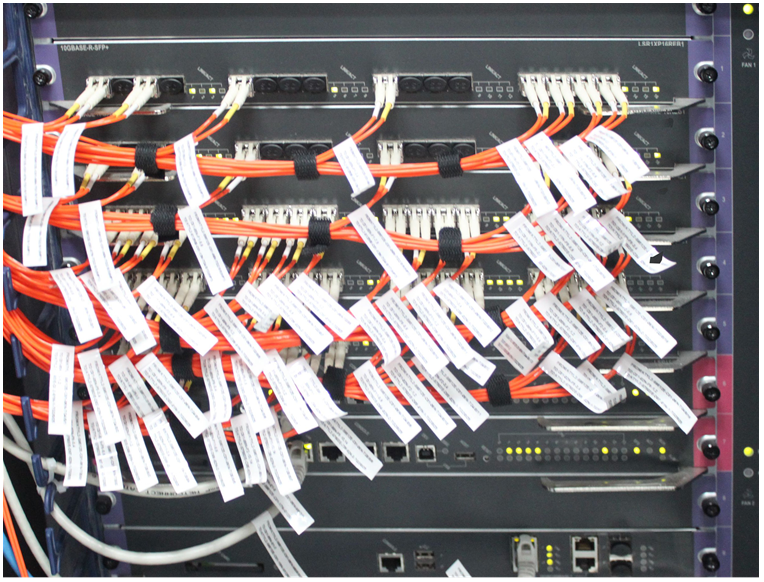

Network cable management

Figure 4 Network cable management

Optical fiber management

|

CAUTION: The core of optical fibers is thin and fragile. Do not use cable ties to bind the optical fibers. Use soft binding tapes to carefully bind optical fibers. Avoid excessive force. For more information, see the binding tape use instructions. |

Figure 5 Optical fiber management

Power cord management

Route the power cords according to the actual conditions in the equipment room, such as the locations of power distribution cabinets, receptacles, and lightning protection boxes. When routing AC power cords, connect them to a power distribution cabinet in the equipment room through PDUs on the rack or through a grounding strip. When routing DC power cords, connect them directly to a power distribution cabinet in the equipment room.

For future device maintenance, avoid blocking the device modules, such as fan trays, when routing power cords.

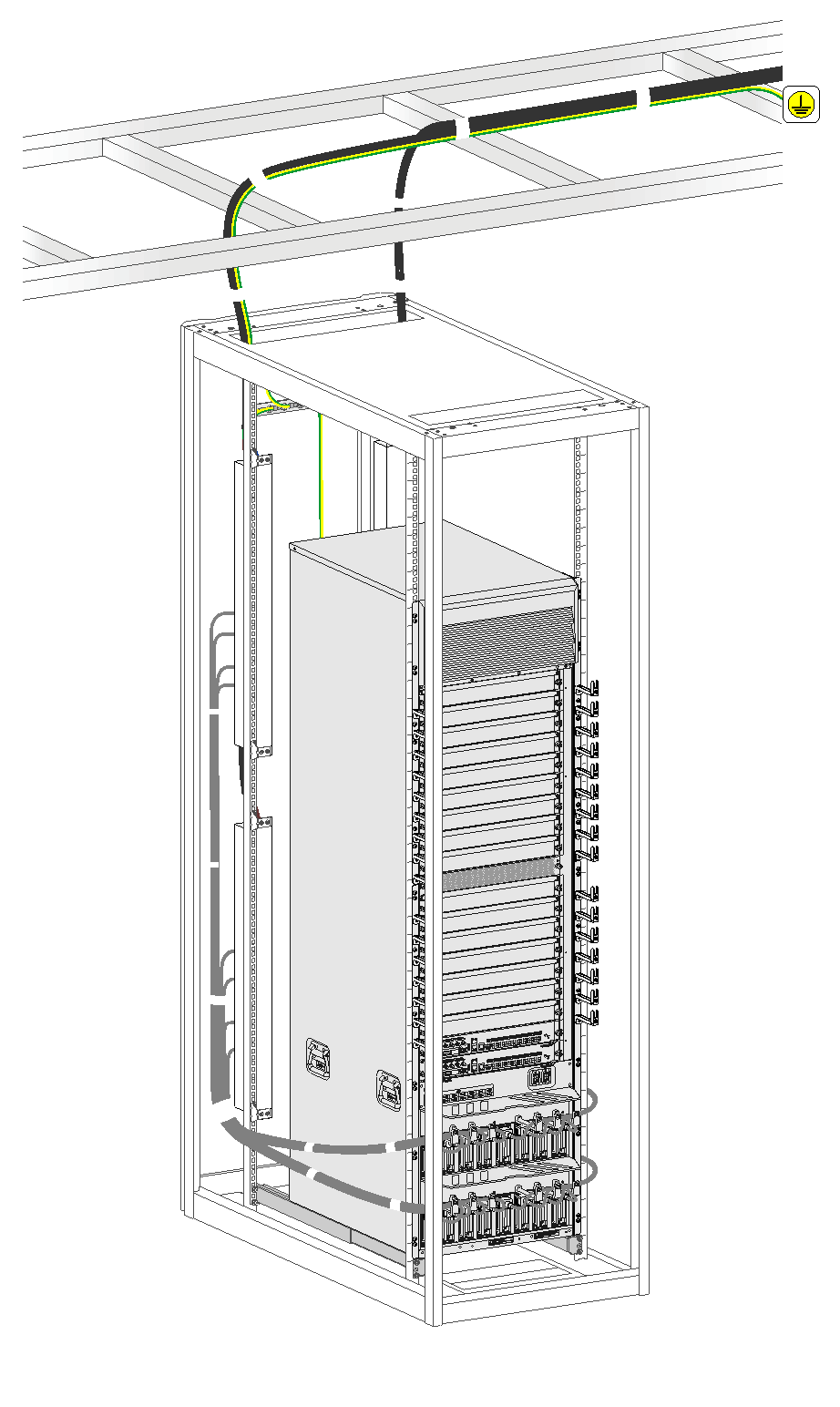

Figure 6 Routing AC power cords

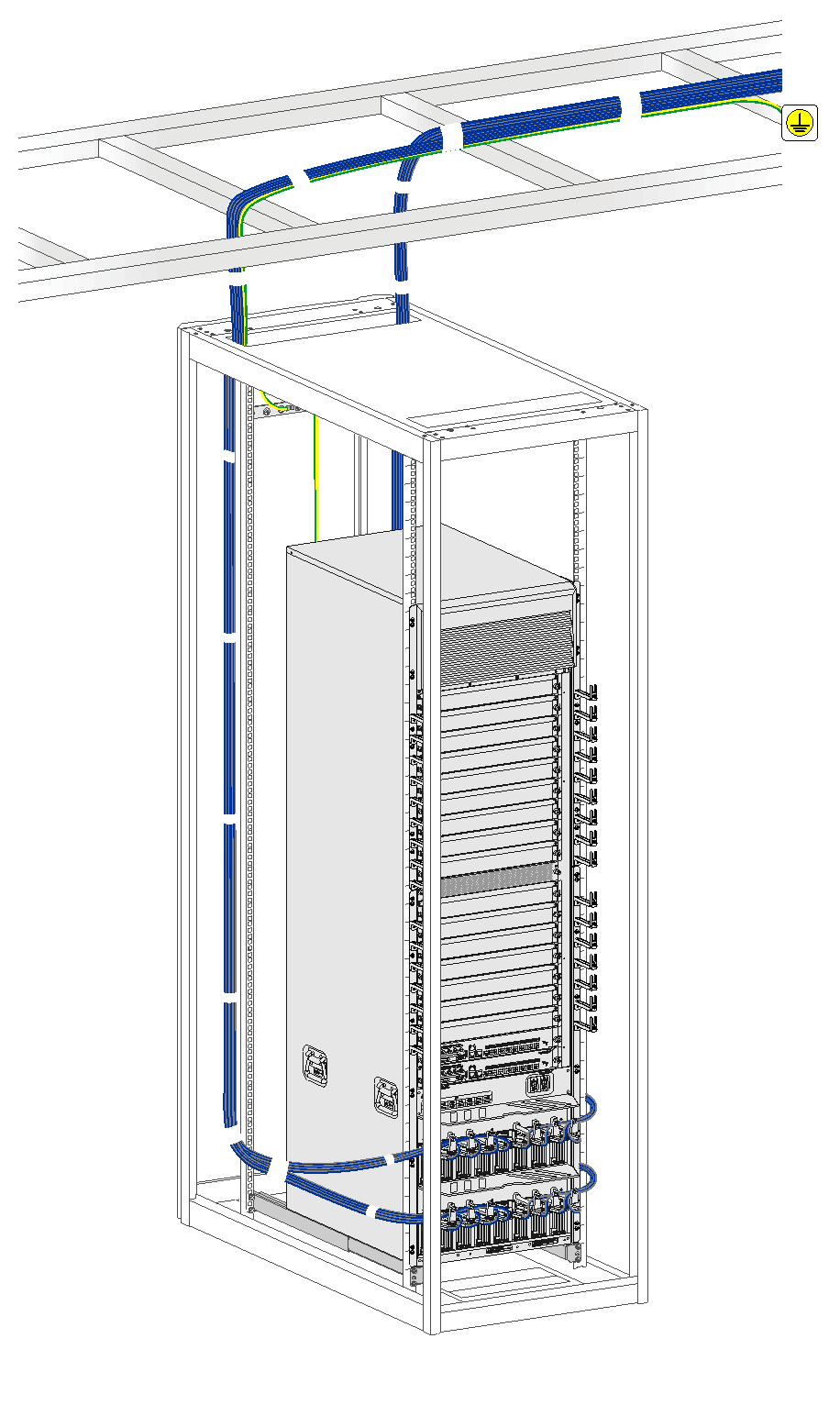

Figure 7 Routing DC power cords