- Table of Contents

-

- H3C WSG1808X-PWR Wireless Integrated Services Gateway Installation Guide-5W101

- 00-Preface

- 01-Preparing for installation

- 02-Installing the device

- 03-Log in to the device

- 04-Hardware management and maintenance

- 05-Troubleshooting

- 06-Appendix A Chassis views and technical specifications

- 07-Appendix B LEDs

- 08-Appendix C Optional transceiver modules

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 02-Installing the device | 536.47 KB |

Installing the device

|

WARNING! Keep the tamper-proof seal on a mounting screw on the chassis cover intact, and if you want to open the chassis, contact H3C Support for permission. Otherwise, H3C shall not be liable for any consequence caused thereby. |

Confirming installation preparations

Before you install the device, verify that you have read "Preparing for installation" carefully and the installation site meets all the requirements.

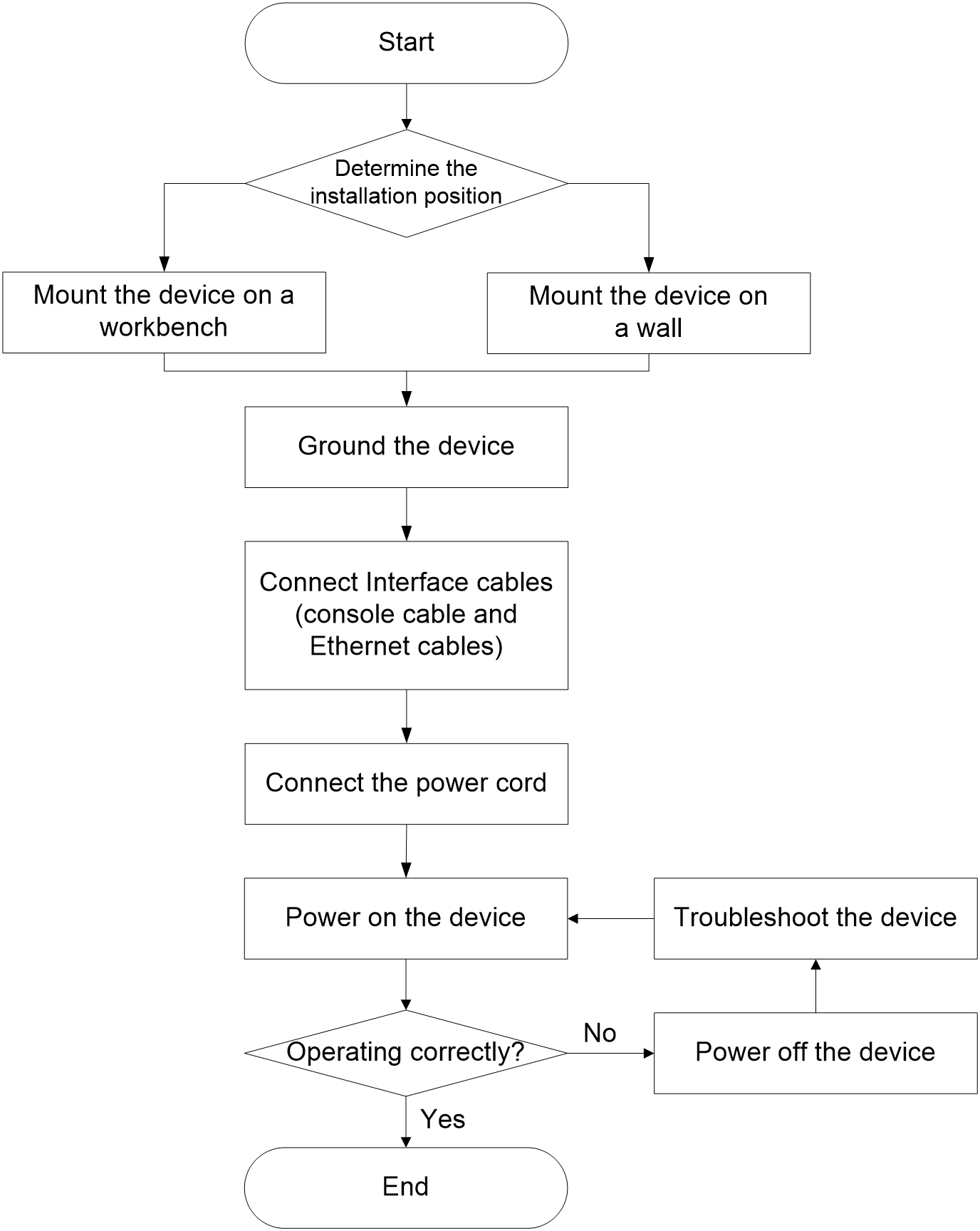

Installation flowchart

Figure2-1 Installation flowchart

Mounting the device on a workbench

|

CAUTION: Do not place heavy objects on the device. |

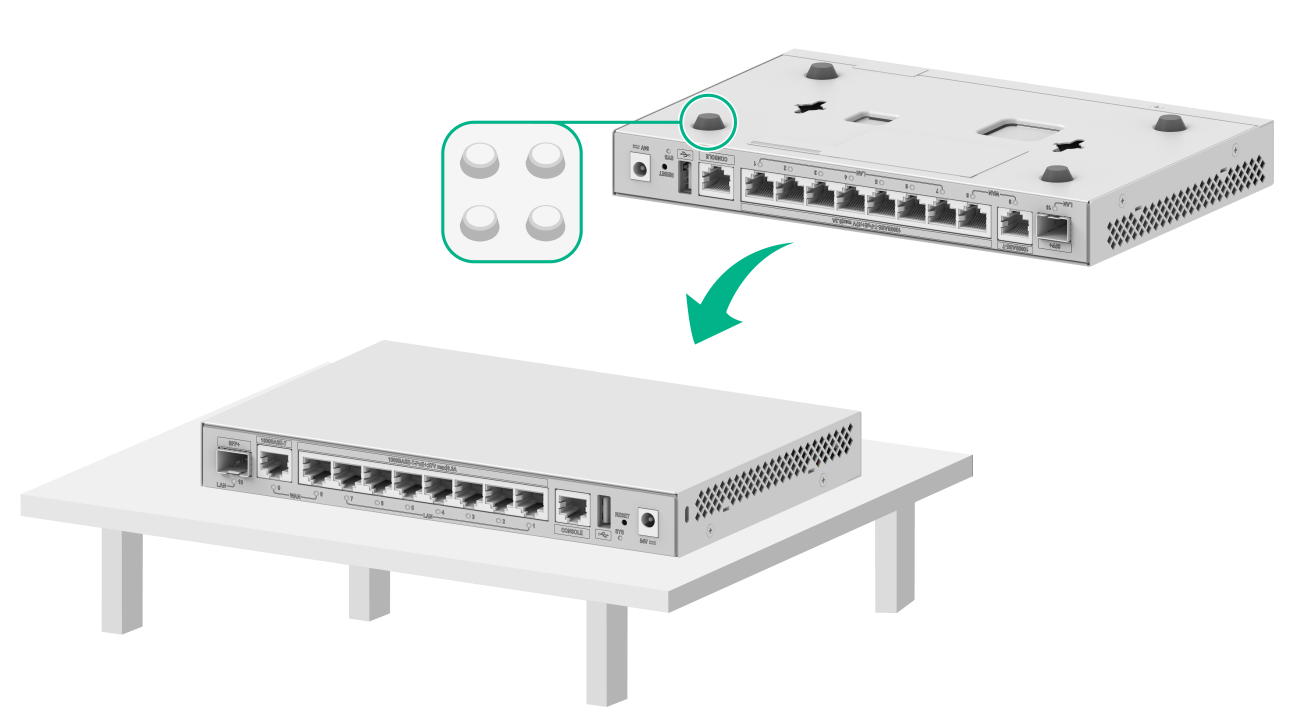

To mount the device on a workbench:

1. Place the device upside down. Clean the recessed areas on the chassis bottom.

2. Attach the four rubber feet to the recessed areas on the chassis bottom.

3. Place the device on the workbench with the upside up. Make sure the four rubber feet stand firmly on the workbench.

Figure2-2 Mounting the device on a workbench

Mounting the device on a wall

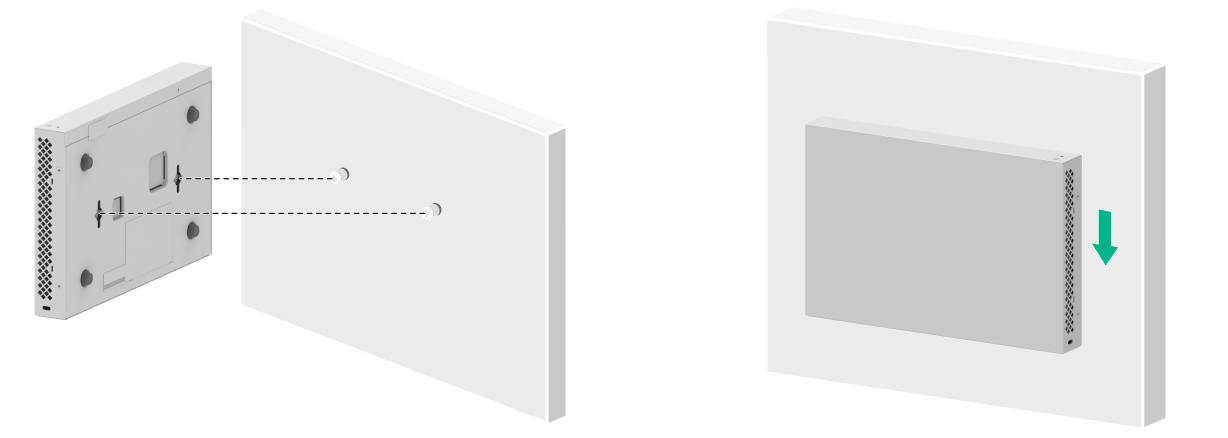

To mount the device on a wall:

1. Mark the installation holes on the wall.

Figure2-3 Installation hole spacing

2. Drill two holes with a diameter of 6 mm (0.24 in) and a depth of 30 mm (1.18 in) at the marked locations.

Figure2-4 Drilling installation holes

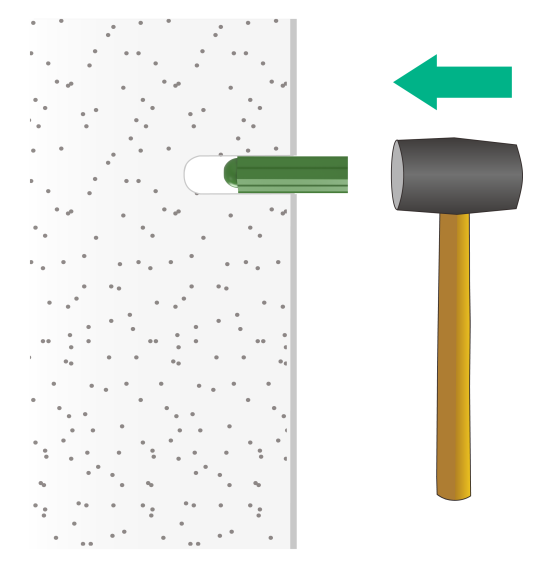

3. Insert an expansion anchor into each hole, and tap the expansion anchor with a rubber hammer until it is all flush with the wall surface.

Figure2-5 Hammering the expansion anchor into the wall

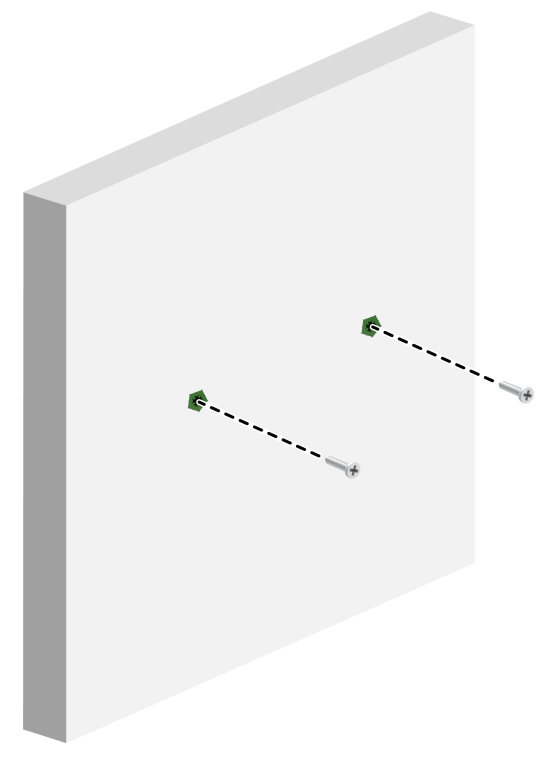

4. Fasten the self-tapping screws to secure the expansion anchors to the wall.

Figure2-6 Fastening self-tapping screws

5. Align the holes on the rear of the device with the self-tapping screws. Hang the device on the self-tapping screws and then slide the device down to secure it to the wall.

Figure2-7 Securing the device to the wall

Grounding the device

|

WARNING! · Correctly connecting the grounding cable is crucial to lightning protection and EMI protection. Before installing or using the device, connect the grounding cable for it correctly. · Connect the grounding cable to the grounding system in the equipment room. Do not connect it to a fire main or lightning rod. |

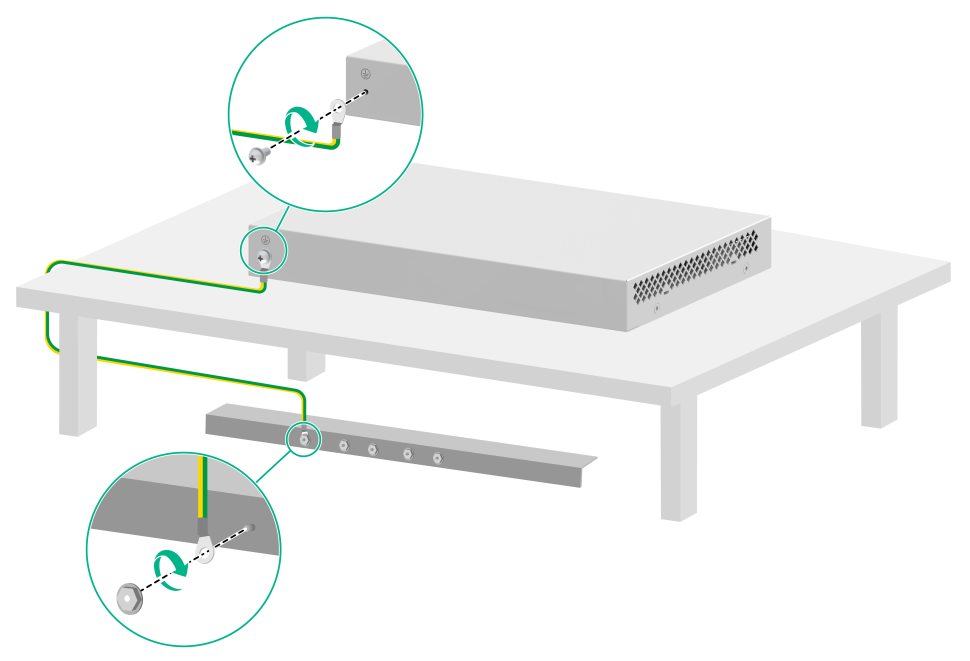

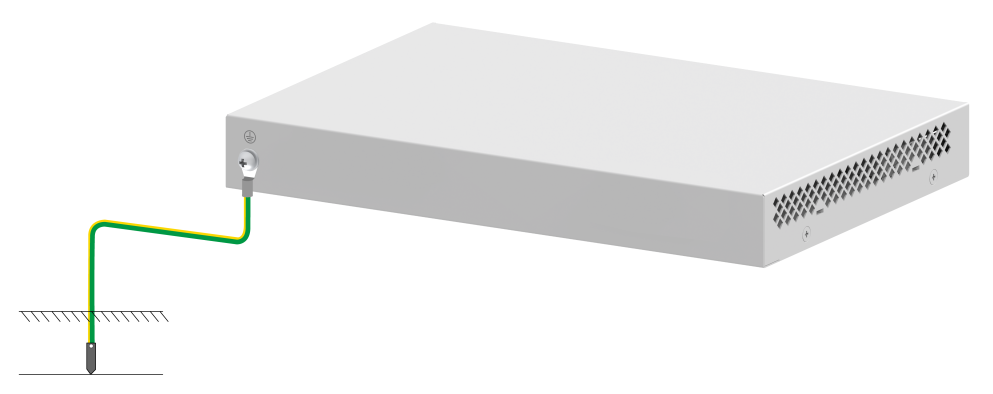

To ground the device:

1. Use a Phillips screwdriver to remove the grounding screw from the chassis rear panel.

2. Use the grounding screw to attach a ring terminal of the grounding cable to the chassis.

3. Use one of the following methods to connect the other end of the grounding cable:

¡ Grounding the device by using a grounding strip

If a grounding strip is available, you can connect the other end of the grounding cable to the grounding strip. Make sure the grounding strip is grounded reliably.

Figure2-8 Grounding the device with a grounding strip

¡ Grounding the device with a grounding conductor buried in the earth

If earth is available at the installation site, you can ground the device with a grounding conductor buried in the earth.

Hammer a 0.5 m (1.64 ft) or longer angle iron or steel tube into the earth to serve as a grounding conductor. Weld the yellow-green grounding cable to the angel iron or steel tube and treat the joint for corrosion protection.

Figure2-9 Grounding the device by burying the grounding conductor into the earth

Connecting Interface cables

Connecting the console cable

To configure and manage the device through the console port, you must run a terminal emulator program, TeraTermPro or PuTTY, on your configuration terminal. For more information about the terminal emulator programs, see the user guides for these programs

The following are the required terminal settings:

· Bits per second—9600.

· Data bits—8.

· Stop bits—1.

· Parity—None.

· Flow control—None.

Connecting Ethernet cables

Connecting an Ethernet copper port

1. Connect one end of the Ethernet cable to the Ethernet copper port on the device, and the other end to the Ethernet port on the peer device.

2. After powering on the device, examine the LEDs of the fixed Ethernet copper port.

For more information about the LED description, see "Appendix B LEDs."

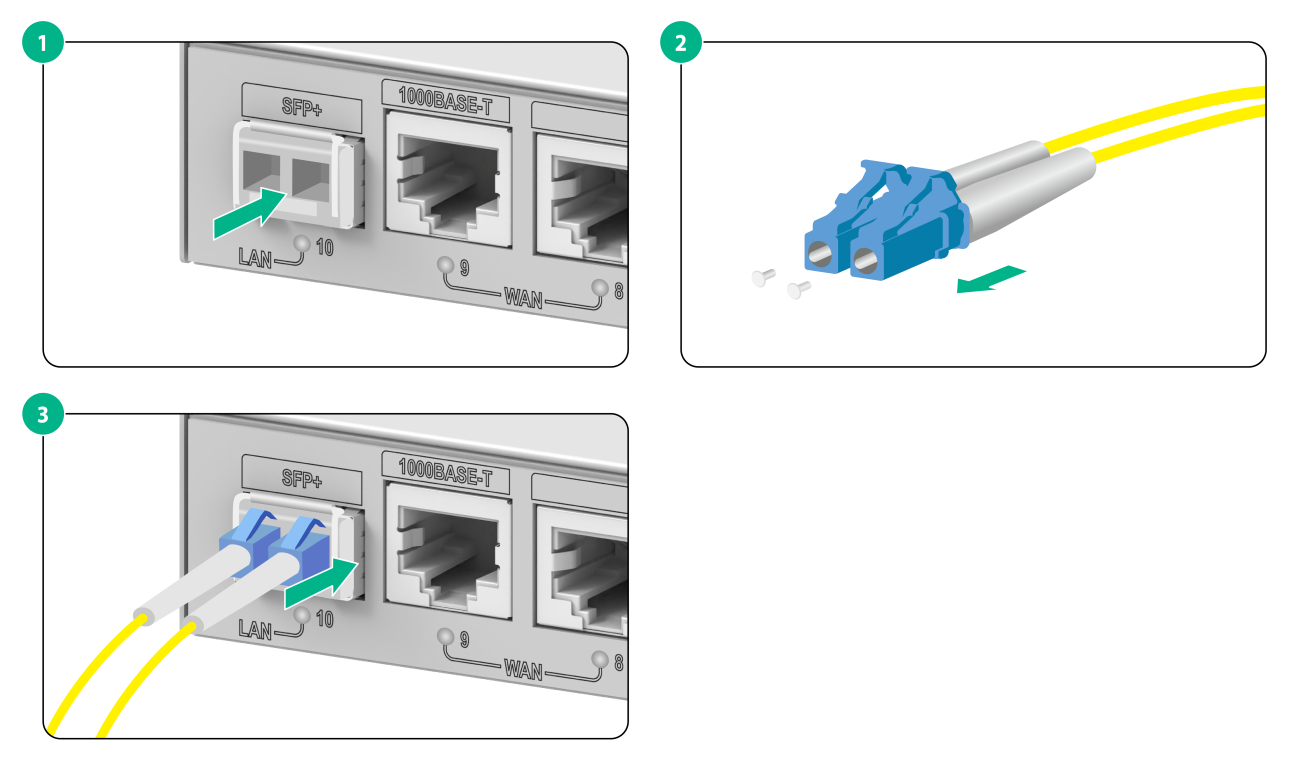

Connecting a fiber port

|

WARNING! Do not stare into any open apertures of operating transceiver modules or optical fiber connectors. The laser light emitted from these apertures might hurt your eyes. |

|

CAUTION: · To connect a fiber port by using an optical fiber, first install a transceiver module in the port and then connect the optical fiber to the transceiver module. · Insert a dust cap into any open optical fiber connector and a dust plug into any open fiber port or transceiver module port to protect them from contamination and ESD damage. · Never bend an optical fiber excessively. The bend radius of an optical fiber must be not less than 10 cm (3.94 in). · Keep the fiber end clean. · Make sure the Tx and Rx ports on a transceiver module are connected to the Rx and Tx ports on the peer end, respectively. |

No transceiver modules are provided with the device. Purchase transceiver modules yourself as required. For more information about the transceiver modules, see "Appendix C Optional transceiver modules."

The fiber ports on the device support only LC connectors.

To connect an optical fiber for a fiber port:

1. Remove the dust plug from the fiber port.

2. Pivot the bail latch of the transceiver module up so that it catches a knob on the top of the transceiver module.

3. Holding both sides of the transceiver module, insert the transceiver module slowly into the port.

4. Identify the Rx and Tx ports on the transceiver module and remove the dust caps from the optical fiber connectors. Use the optical fiber to connect the Rx port and Tx port on the transceiver module to the Tx port and Rx port on the peer end, respectively.

5. Examine the port LEDs:

¡ If the LED is on, a fiber link has been set up.

¡ If the LED is off, the link has not been set up. The reason might be wrong connection of the Tx and Rx ends. Swap the fiber connectors in the Tx and Rx ports at one end of the fiber.

Figure2-10 Connecting an optical fiber

Connecting the power cord

|

WARNING! To avoid bodily injury, first connect the power cord to the device, and then connect the power cord to the power source. |

|

CAUTION: Before connecting the power cord, make sure the device is grounded correctly. |

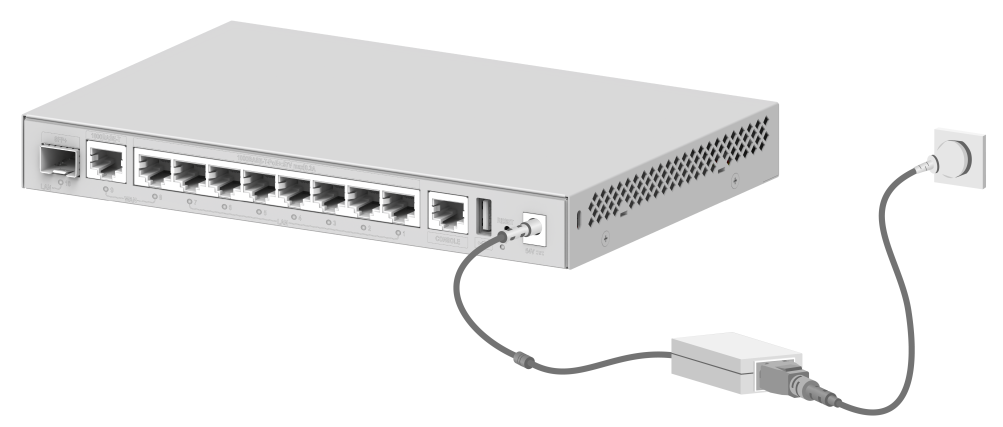

To connect the power cord:

1. Connect one end of the AC power cord to the DC power input receptacle on the device.

2. Connect the other end of the AC power cord to the AC power source.

Figure2-11 Connecting the power cord

Verifying the installation

Before powering on the device, verify the following information:

· There is enough space around the device for heat dissipation.

· The work bench is sturdy.

· The grounding cable is securely connected.

· The Ethernet cables, optical fibers, and power cord are connected correctly.

Powering on the device

|

|

NOTE: The following procedure uses the EWP-WSG1808X-PWR access controller as an example. |

1. Power on the device. The device initializes its memory and runs the BootWare. The following information appears on the terminal screen:

System is starting...

Press Ctrl+Y to download basic bootware

Press Ctrl+D to access BASIC-BOOTWARE MENU...

Press Ctrl+T to start heavy memory test

Booting Normal Extended BootWare.

The Extended BootWare is self-decompressing....Done.

****************************************************************************

* *

* H3C WSG1808X-PWR BootWare, Version 1.11 *

* *

****************************************************************************

Compiled Date : Jun 12 2023

Memory Type : DDR4 SDRAM

Memory Speed : 2666MHz

Memory Size : 2048MB

PCB Version : Ver.B

flash Size : 3728MB

BootWare Validating...

Press Ctrl+B to access EXTENDED-BOOTWARE MENU...

2. Press Ctrl + B at the prompt within 4 seconds to access the Boot menu.

To access the Boot menu after the system enters the system image file reading and self-compressing process, restart the device.

Loading the main image files...

Loading file flash:/system.bin......Done.

Loading file flash:/boot.bin............Done.

Image file flash:/boot.bin is self-decompressing.....Done.

System image is starting...

Cryptographic algorithms tests passed.

Line con0 is available.

Press ENTER to get started.

3. Press Enter at the prompt, and you can configure the device when the prompt <H3C> appears.