- Table of Contents

-

- H3C WX1800H Series Access Controllers Installation Guide-6W102

- 00-Preface

- 01-Preparing for installation

- 02-Installing the device

- 03-Troubleshooting

- 04-Hardware management and maintenance

- 05-Appendix A Chassis views and technical specifications

- 06-Appendix B LEDs

- 07-Appendix C Optional transceiver modules

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 01-Preparing for installation | 573.83 KB |

1 Preparing for installation

H3C WX1800H series access controllers include the following models:

· WX1804H-PWR

· WX1810H-PWR

· WX1820H

· WX1840H

The supported models vary depending on your country or region.

Safety recommendations

To avoid any equipment damage or bodily injury, read the following safety recommendations before installation. Note that the recommendations do not cover every possible hazardous condition.

Safety symbols

When reading this document, note the following symbols:

![]() WARNING means an alert that calls attention to important information that if

not understood or followed can result in personal injury.

WARNING means an alert that calls attention to important information that if

not understood or followed can result in personal injury.

![]() CAUTION means an alert that calls attention to important information that if

not understood or followed can result in data loss, data corruption, or damage

to hardware or software.

CAUTION means an alert that calls attention to important information that if

not understood or followed can result in data loss, data corruption, or damage

to hardware or software.

General safety recommendations

· Make sure the installation site is flat, vibration-free, and away from electromagnetic interferences. Make sure ESD and anti-slip measures are in place.

· Keep the chassis and installation tools away from walk areas.

· Do not place the device on an unstable case or desk. The device might be severely damaged in case of a fall.

· Keep the chassis clean and dust-free.

· Do not place the device near water or in a damp environment. Prevent water or moisture from entering the device chassis.

· Remove all cables from the device before moving it.

· Ensure good ventilation in the equipment room and make sure the air inlet and outlet vents of the device are not blocked.

· Make sure the power voltage for the device is in the acceptable range.

· Use a screwdriver to fasten screws.

· After you move the device from a location below 0°C (32°F) to the equipment room, follow these guidelines to prevent condensation:

¡ Wait a minimum of 30 minutes before unpacking the device.

¡ Wait a minimum of 2 hours before powering on the device.

Electricity safety

· Carefully examine your work area for possible hazards, such as moist floors, ungrounded power sources, or missing safety grounds.

· Locate the emergency power-off switch in the room before installation. Shut off the power immediately if an accident occurs. Remove the power cord if necessary.

· Do not work alone when you operate the device with power on.

· Always verify that the power has been disconnected when you perform operations that require the device to be powered off.

Laser safety

|

|

WARNING! Disconnected optical fibers or connectors might emit invisible laser light. Do not stare into beams or view directly with optical instruments when the switch is operating. |

|

|

CAUTION: · Before you remove the optical fiber connector from a fiber port, execute the shutdown command in interface view to shut down the port. · Insert a dust cap into any open optical fiber connector and a dust plug into any open fiber port or transceiver module port to protect them from contamination and ESD damage. |

Examining the installation site

The device can only be used indoors. For the device to operate correctly and have a prolonged service time, the installation site must meet the following requirements.

Temperature and humidity

Make sure the temperature and humidity in the equipment room meet the requirements described in Table1-1.

· Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical property change of materials, and metal corrosion.

· Lasting low relative humidity can cause washer contraction and ESD and cause problems including loose mounting screws and circuit failure.

· High temperature can accelerate the aging of insulation materials and significantly lower the reliability and lifespan of the device.

Table1-1 Temperature and humidity requirements for the equipment room

|

Temperature |

Humidity |

|

· WX1804H-PWR/WX1820H: 0°C to 40°C (32°F to 104°F) · WX1810H-PWR/WX1840H: 0°C to 45°C (32°F to 113°F) |

5% RH to 95% RH, noncondensing |

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of metal components and contact points, especially when indoor relative humidity is low. In the worst case, electrostatic adsorption can cause communication failure.

Table1-2 Dust concentration limit in the equipment room

|

Substance |

Concentration limit (particles/m3) |

|

Dust particles |

≤ 3 x 104 (No visible dust on desk in three days) |

|

NOTE: Dust particle diameter ≥ 5 µm |

|

The equipment room must also meet limits on salts, acids, and sulfides to eliminate corrosion and premature aging of components, as shown in Table1-3.

Table1-3 Harmful gas limits in the equipment room

|

Gas |

Max. (mg/m3) |

|

SO2 |

0.2 |

|

H2S |

0.006 |

|

NH3 |

0.05 |

|

Cl2 |

0.01 |

|

NO2 |

0.04 |

Cooling

The device uses left-to-right airflow. For adequate heat dissipation, plan the installation site for the device based on its airflow direction and make sure the following requirements are met:

· A minimum clearance of 100 mm (3.94 in) is reserved around the device.

· The workbench or rack where the device is to be installed has a good ventilation system.

Figure1-1 Airflow through the chassis (WX1840H)

ESD prevention

ESD prevention guidelines

To prevent electrostatic discharge (ESD), follow these guidelines:

· Make sure the device is reliably grounded.

· Take dust-proof measures for the equipment room.

· Maintain the humidity and temperature in the equipment room at acceptable levels.

· When working with the device, always wear an ESD wrist strap or gloves and ESD garment, and remove conductive objects such as jewelry or watch. Make sure the wrist strap makes good skin contact and is reliably grounded.

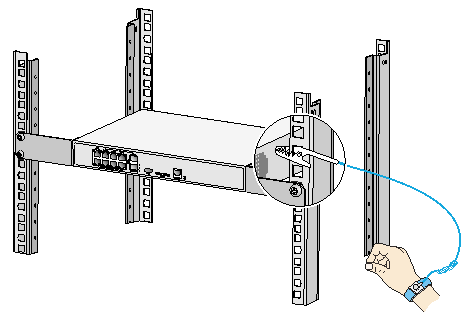

Attaching an ESD wrist strap

No ESD wrist strap is provided with the device. Prepare one yourself.

To attach an ESD wrist strap:

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to maintain good contact with the skin.

3. Secure the wrist strap lock and the alligator clip lock together.

4. Attach the alligator clip to the rack.

5. Make sure the rack is reliably grounded.

Figure1-2 Attaching an ESD wrist strap (WX1840H)

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the device and application system, adversely affect the device in the following ways:

· A conduction pattern of capacitance coupling.

· Inductance coupling.

· Electromagnetic wave radiation.

· Common impedance (including the grounding system) coupling.

To prevent EMI, use the following guidelines:

· Take effective measures to filter interference from the power grid.

· Keep the device far away from radio transmitting stations, radar stations, and high-frequency devices.

· Use electromagnetic shielding, for example, shielded interface cables, when necessary.

· To prevent signal ports from getting damaged by overvoltage or overcurrent caused by lightning strikes, route interface cables only indoors.

Lightning protection

To enhance lightning protection for the device, follow these guidelines:

· Make sure the device is reliably grounded.

· Make sure the AC power outlet is reliably grounded.

· Install a surge protected power strip at the power input end.

Installation accessories

Figure1-3 Installation accessories

|

Installation accessory |

WX1804H-PWR |

WX1810H-PWR |

WX1820H |

WX1840H |

|

|

Cage nut |

|

N/A |

4, user supplied |

N/A |

4, user supplied |

|

M6 rack screw |

|

N/A |

4, user supplied |

N/A |

4, user supplied |

|

M4 mounting bracket screw |

|

N/A |

4 |

N/A |

4 |

|

Rubber feet |

|

1 |

1 |

1 |

1 |

|

Grounding cable |

|

N/A |

1 |

N/A |

1 |

|

Ring terminal |

|

1 |

N/A |

1 |

N/A |

|

Console cable |

|

N/A |

1 |

1 |

1 |

|

Power adapter |

|

1 |

N/A |

N/A |

N/A |

|

Power adapter |

|

N/A |

N/A |

1 |

N/A |

|

Power cord |

|

1 |

N/A |

1 |

N/A |

|

Bail latch |

|

N/A |

N/A |

N/A |

1 |

|

Front mounting bracket |

|

N/A |

N/A |

N/A |

2 |

|

Front mounting bracket |

|

N/A |

2 |

N/A |

N/A |

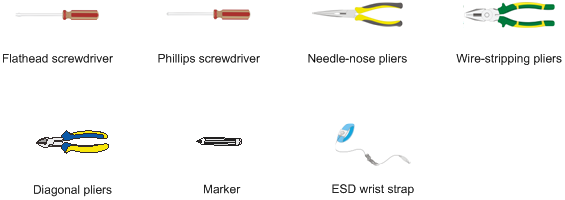

Installation tools

No installation tools are provided with the device. Prepare them yourself as required.

Figure1-4 Installation tools

Pre-installation checklist

Table1-4 Pre-installation checklist

|

Item |

Requirements |

Result |

|

|

Installation site |

Ventilation |

· A minimum clearance of 10 cm (3.9 in) is reserved around the chassis. · The installation site has a good ventilation system. |

|

|

Temperature |

· WX1804H-PWR/WX1820H: 0°C to 40°C (32°F to 104°F) · WX1810H-PWR/WX1840H: 0°C to 45°C (32°F to 113°F) |

|

|

|

Humidity |

5% RH to 95% RH (noncondensing). |

|

|

|

Cleanliness |

· Dust concentration ≤ 3 x 104 particles/m3. · No visible dust on desk within three days. |

|

|

|

ESD prevention |

· The device is reliably grounded. · Dust-proof measures are taken in the equipment room. · Humidity and temperature are maintained in the acceptable range. |

|

|

|

EMI prevention |

· Effective measures are taken for filtering interference from the power grid. · The protection ground of the device is away from the grounding facility of power equipment or lightning protection grounding facility. · The device is far away from radio transmitting stations, radar stations, and high-frequency devices. · Electromagnetic shielding, for example, shielded interface cables, is used as required. |

|

|

|

Lightning protection |

· The device is reliably grounded. · The AC power source is reliably grounded. · (Optional.) Network port lightning protectors are available. · (Optional.) A surge protected power strip is available. |

|

|

|

Electricity safety |

· A UPS is available. · The power-off switch in the equipment room is identified and accessible so that the power can be immediately shut off when an accident occurs. |

|

|

|

Safety precautions |

The device is far away from any sources of heat or moisture. |

|

|

|

Accessories |

Installation accessories supplied with the device are available. |

|

|

|

Reference |

· Documents shipped with the device are available. · Online documents are available. |

|

|