- Table of Contents

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 01-Text | 16.04 MB |

Contents

General safety recommendations

Examining the installation site

Rack or workbench requirements

Installing the router in a standard 19-inch rack

Router dimensions and rack requirements

Installing cable management brackets

4 Installing removable components

Install an HMIC interface module

Installing a power supply and connecting the power cord

Installing an AC power supply and connecting the power cord

Installing a DC power supply and connecting the power cord

Connecting copper Ethernet cables

7 Accessing the router for the first time

Connecting the router to a configuration terminal

8 Replacing removable components

Replace an HMIC interface module

9 Hardware management and maintenance

Displaying software and hardware version information for the router

Displaying the operational statistics about the router

Displaying detailed information about the router

Displaying electrical label information for the router

Displaying the CPU usage of the router

Displaying the memory usage of the router

Displaying the operational status of fan trays

Displaying the operational status of power supplies

Displaying temperature information for the router

Displaying transceiver module information

Diagnosing transceiver modules

Saving the running configuration

Rebooting the router or a module

Configuration terminal display issue

Interface module, cable, and connection failure

System failure during operation

Guidelines for using the reset button

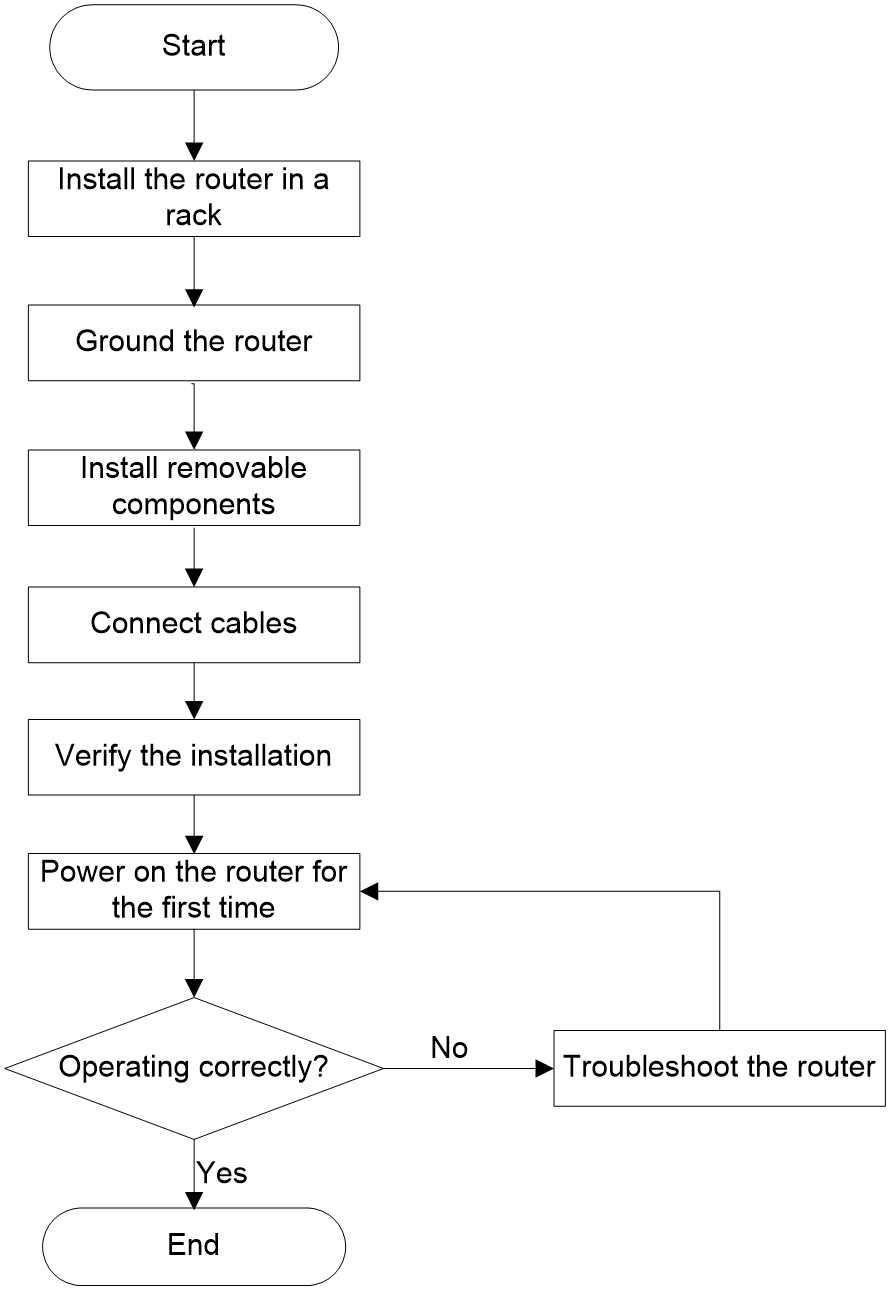

1 Router installation flow

The installation flow for the router is as described in Figure1-1.

Figure1-1 Router installation flow

2 Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury, read the following safety recommendations before installation. Note that the recommendations do not cover every possible hazardous condition.

General safety recommendations

· Do not place the router on an unstable case or desk. The router might be severely damaged in case of a fall.

· Keep the chassis clean and dust-free.

· Do not place the router on a moist area, and avoid liquid flowing into the router. Do not use wet cloth to wipe the router.

· Handle the routers according to the sizes of and packaging symbols on the packages.

Electrical safety

· Clear the work area of possible electricity hazards, such as ungrounded power extension cables, missing safety grounds, and wet floors.

· Locate the emergency power-off switch in the room before installation so you can quickly shut power off when an electrical accident occurs.

· Make sure the operating voltage is in the required range.

· Before powering on the router, make sure the router is reliably grounded.

Laser safety

|

WARNING! Disconnected optical fibers or transceiver modules might emit invisible laser light. Do not stare into beams or view directly with optical instruments when the router is operating. |

The router is a Class 1 laser device.

To avoid ESD damage, use dust caps on disconnected optical fiber connectors. Insert a dust plug into each fiber port and each transceiver module port not in use.

Moving safety

When you move the router, follow these guidelines:

· To avoid damage, move and unpack the router with care.

· After you move the router from a location below 0°C (32°F) to the equipment room, follow these guidelines to prevent condensation:

¡ Wait a minimum of 30 minutes before unpacking the router.

¡ Wait a minimum of 2 hours before powering on the router.

· Before you move the router, remove all cables.

· If the router is to be transported over a long distance, perform the following tasks before the transport:

¡ Remove all removable components, such as power supplies and interface modules, and place them separately in antistatic bags.

¡ Replace the filler panels provided with the router to prevent obstacle intrusions and damages to the router.

· To transport the router over a short distance, make sure the removable components are securely installed on the router and the screws are tightly fastened.

· When you move or lift the chassis, support the bottom of the chassis, rather than hold any removable component.

ESD prevention

|

CAUTION: Make sure the resistance reading between human body and the ground is in the range of 1 to 10 megohms (Mohms). |

No ESD wrist strap is provided with the router. Purchase one yourself.

Always wear an ESD wrist strap when installing removable components. Make sure the wrist strap is reliably grounded.

To attach the ESD wrist strap:

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Secure the wrist strap lock and the alligator clip lock together.

4. Attach the alligator clip to the rack or the workbench.

Examining the installation site

The router can only be used indoors. To ensure correct operation and a long lifespan for your router, the installation site must meet the following requirements.

Temperature and humidity

Maintain appropriate temperature and humidity in the equipment room at levels as described in Table2-1.

· Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical property change of materials, and metal corrosion.

· Lasting low relative humidity can cause washer contraction and ESD and bring problems including loose captive screws and circuit failure.

· High temperature can accelerate the aging of insulation materials and significantly lower the reliability and lifespan of the router.

Table2-1 Temperature and humidity requirements

|

Item |

Specification |

|

Temperature |

· Operating: 0°C to 45°C (32°F to 113°F) · Storage: –40°C to +70°C (–40°F to +158°F) |

|

Humidity |

· Operating: 5% RH to 95% RH, noncondensing · Storage: 5% RH to 95% RH, noncondensing |

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of metal components and contact points, especially when indoor relative humidity is low. In the worst case, electrostatic adsorption can cause communication failure.

Table2-2 Router requirement for cleanliness

|

Substance |

Particle diameter |

Concentration limit |

|

Dust particles |

≥ 0.5 µm |

≤ 1.8 × 107 particles/m3 |

Corrosive gases can accelerate corrosion and aging of metal components. Make sure the corrosive gases do not exceed the concentration limits as shown in Table2-3.

Table2-3 Corrosive gas concentration limits

|

Gas |

Average concentration (mg/m3) |

Maximum concentration (mg/m3) |

|

SO2 |

0.3 |

1.0 |

|

H2S |

0.1 |

0.5 |

|

Cl2 |

0.1 |

0.3 |

|

HCI |

0.1 |

0.5 |

|

HF |

0.01 |

0.03 |

|

NH3 |

1.0 |

3.0 |

|

O3 |

0.05 |

0.1 |

|

NOX |

0.5 |

1.0 |

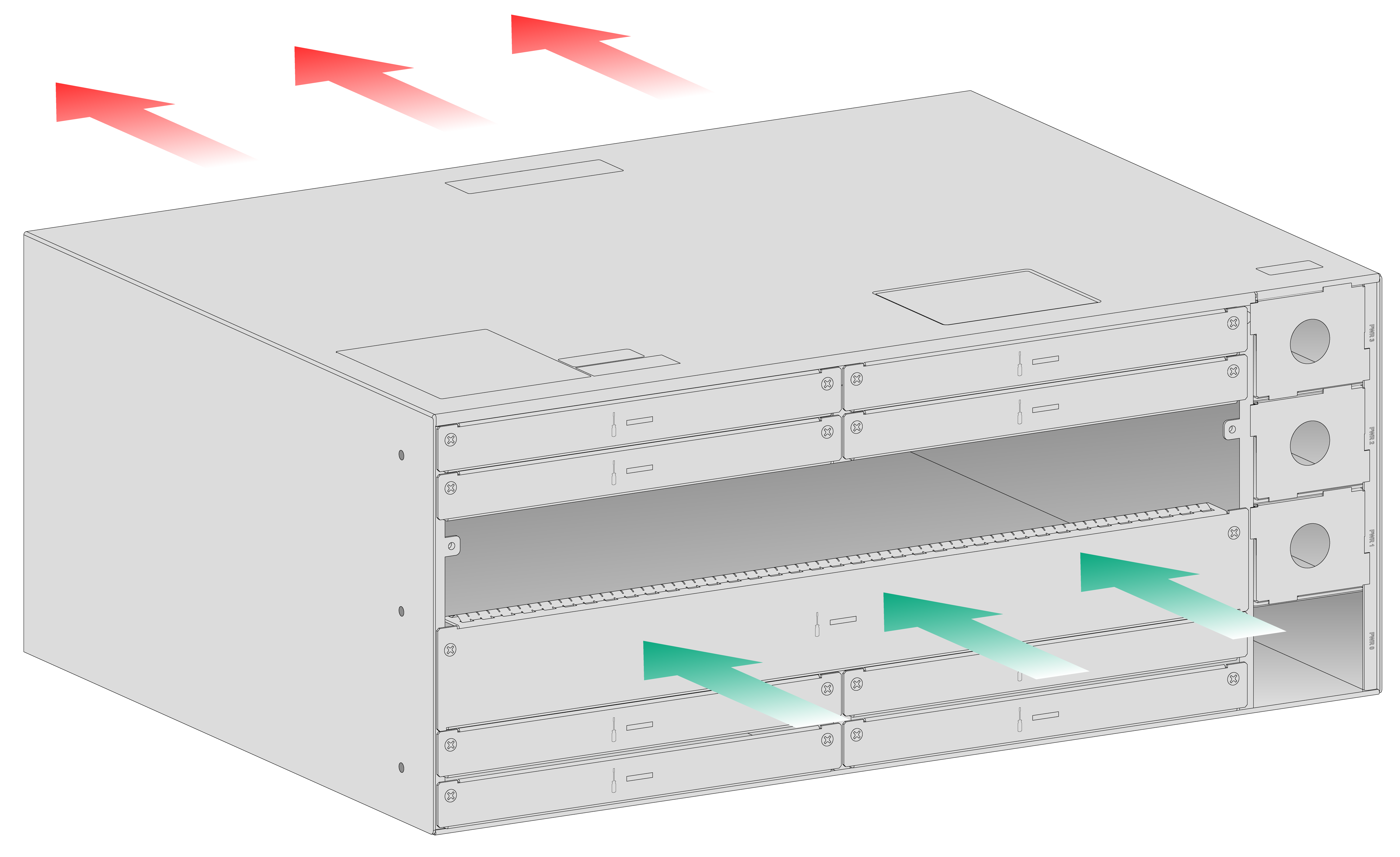

Cooling system

For adequate cooling of the router, make sure the following requirements are met:

· A minimum clearance of 10 cm (3.94 in) is reserved around the inlet and outlet air vents.

· The installation site has a good cooling system.

· Plan the cooling system at the installation site based on the airflow direction of the router.

· Verify the airflow directions of the devices above and below the router. Make sure the exhausted hot air of the lower device will not enter the upper device.

Figure2-1 Airflow through the chassis

Rack or workbench requirements

· Make sure the rack or workbench is sturdy enough to support the total weight of the router and its accessories. For more information about the router weight, see H3C SR6608-M Router Hardware Information and Specifications.

· Make sure the dimensions of the rack or workbench meet the requirements.

· Make sure the rack or workbench is reliably grounded.

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the router and application system, adversely affect the router in the following ways:

· A conduction pattern of capacitance coupling.

· Inductance coupling.

· Electromagnetic wave radiation.

· Common impedance (including the grounding system) coupling.

To prevent EMI, use the following guidelines:

· If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to filter interference from the power grid.

· Keep the router far away from radio transmitting stations, radar stations, and high-frequency devices.

· Use electromagnetic shielding, for example, shielded interface cables, when necessary.

Lightning protection

To protect the router from lightning better, do as follows:

· Make sure the installation site, power supply system, and the router are reliably grounded.

· Install a lightning arrester at the input end of the power supply to enhance the lightning protection capability of the power supply.

· To prevent signal ports from getting damaged by overvoltage or overcurrent caused by lightning strikes, route interface cables only indoors. If part of the network cable of an Ethernet port must be routed outdoors, connect a lightning arrester to the cable before you plug the cable into the port.

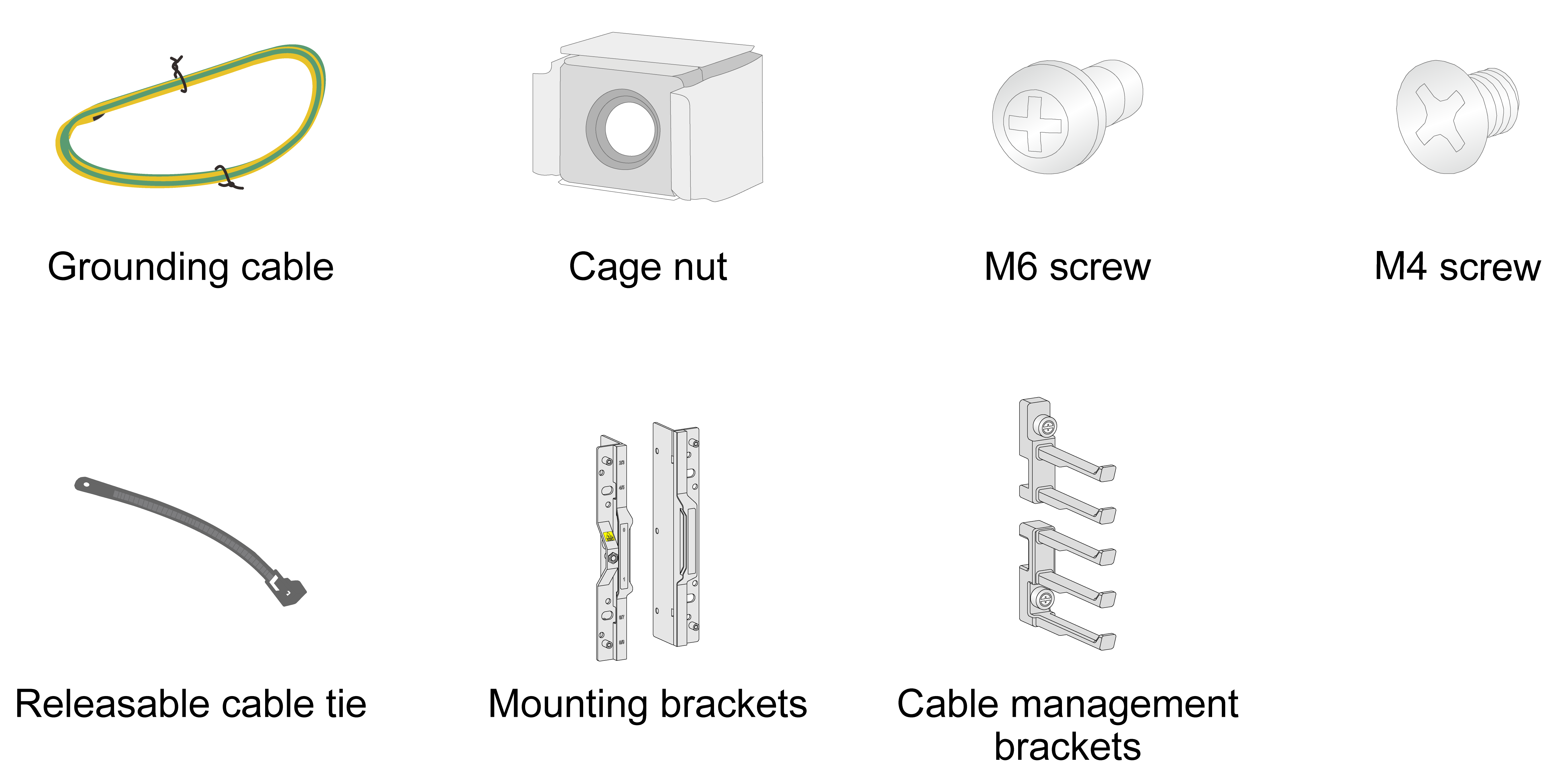

Installation tools

No installation tools are provided with the router. Prepare installation tools yourself as required.

Figure2-2 Installation tools

Installation accessories

Figure2-3 Installation accessories

3 Installing the router

Installing the router in a standard 19-inch rack

|

WARNING! To avoid bodily injury and device damage, a minimum of two persons are required to install the router. |

|

CAUTION: Ensure a clearance of 1 RU (44.45 mm, or 1.75 in) between the router and walls or other devices for heat dissipation. |

Router dimensions and rack requirements

To mount the router in a rack, make sure the rack meets the requirements described in Table3-1.

Table3-1 Router dimensions and rack requirements

|

Router dimensions |

Rack requirements |

|

· Height—175 mm (6.89 in) (4 RU) · Width—440 mm (17.32 in) · Total depth—420 mm (16.54 in) ¡ 330 mm (12.99 in) for the chassis ¡ 60 mm (2.36 in) for the AC/DC power cord at the chassis front ¡ 27 mm (1.06 in) for the fan tray handle at the chassis rear |

A minimum of 0.6 m (1.97 ft) in depth (recommended). · A minimum of 80 mm (3.15 in) between the front rack posts and the front door. · A minimum of 390 mm (15.35 in) between the front rack posts and the rear door. |

|

IMPORTANT: The router does not have rear mounting brackets. To mount it on a rack, use a tray. |

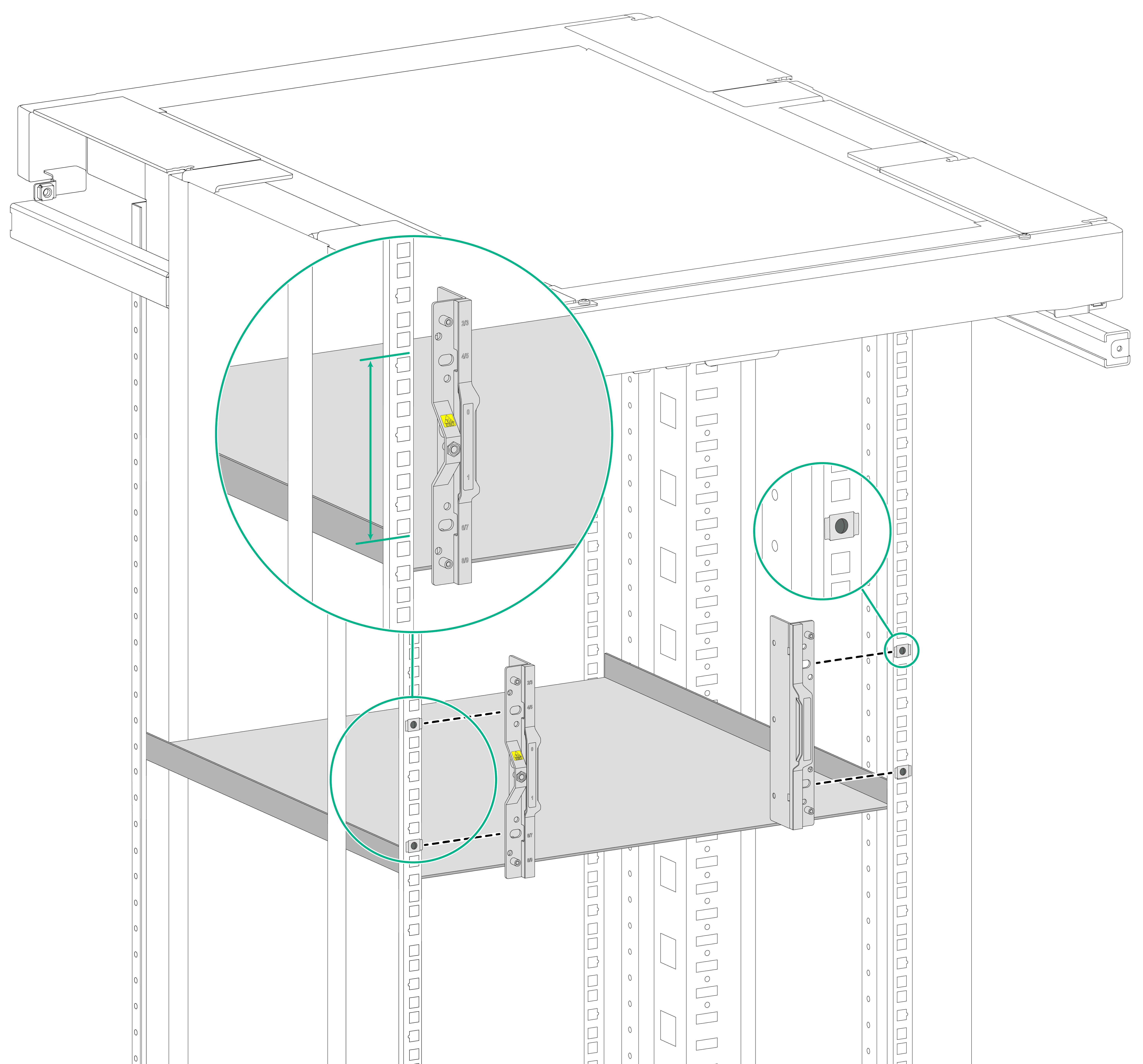

Rack-mounting the router

|

IMPORTANT: Mounting brackets are not used for load bearing but for securing the router to the rack. To use a rack shelf for load bearing, make sure a rack shelf that can bear the weight of the router and its accessories is installed in the rack before rack-mounting the router. |

To install the router by using the mounting brackets and a rack shelf:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Identify the router installation position and secure the rack shelf to the rack.

3. Use the mounting brackets to mark the cage nut installation positions on the front rack posts according to the rack shelf position. Then, install cage nuts at the marked positions.

Figure3-1 Installing cage nuts

4. Place the router horizontally on the rack shelf. Move the router along the rack shelf until the mounting brackets of the router are flush against the front the rack posts.

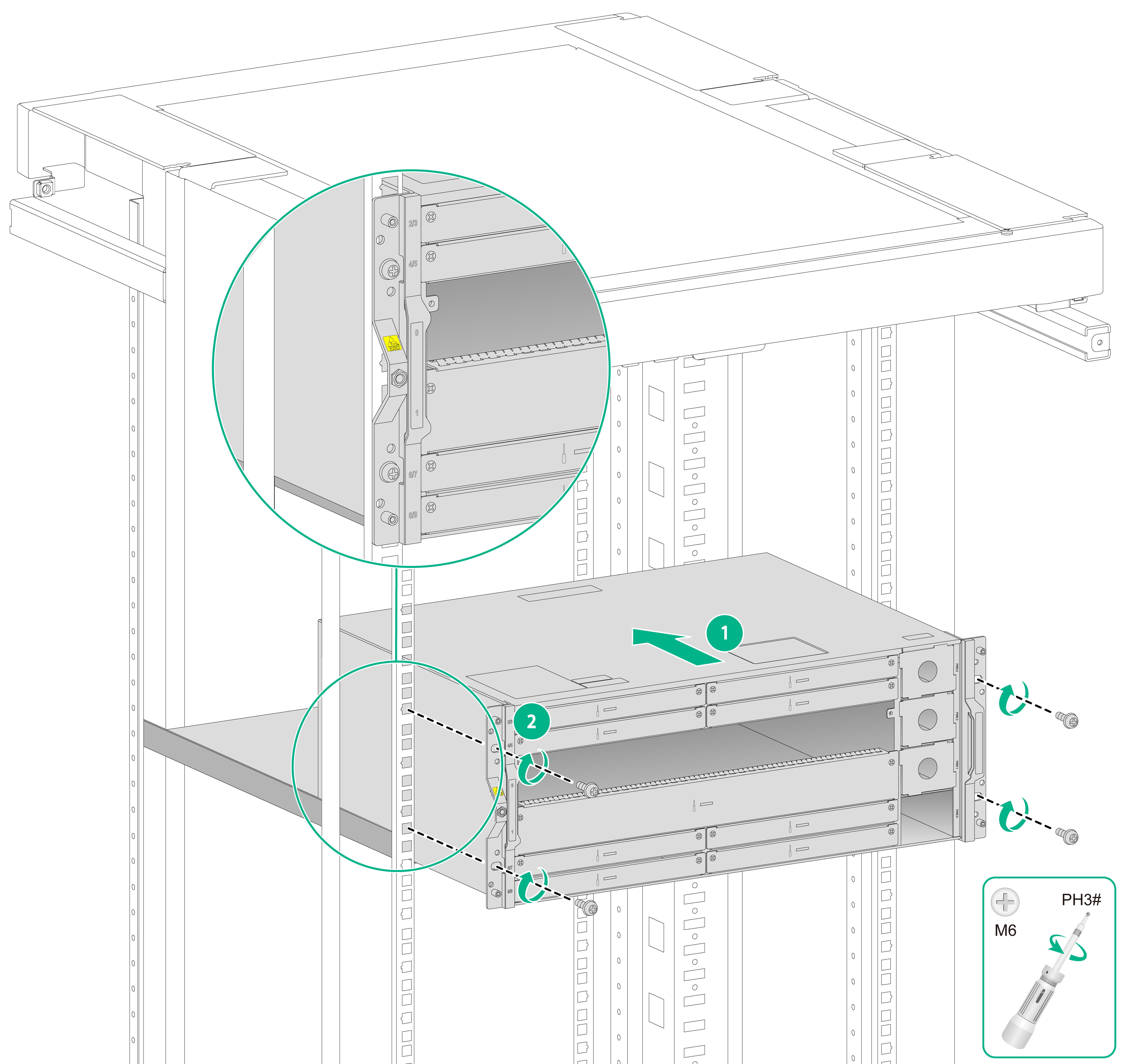

5. Use the M6 screws to secure the mounting brackets to the front rack posts.

Figure3-2 Mounting the router in the rack

Installing cable management brackets

Install cable management brackets after you mount the router in the rack.

To install cable management brackets:

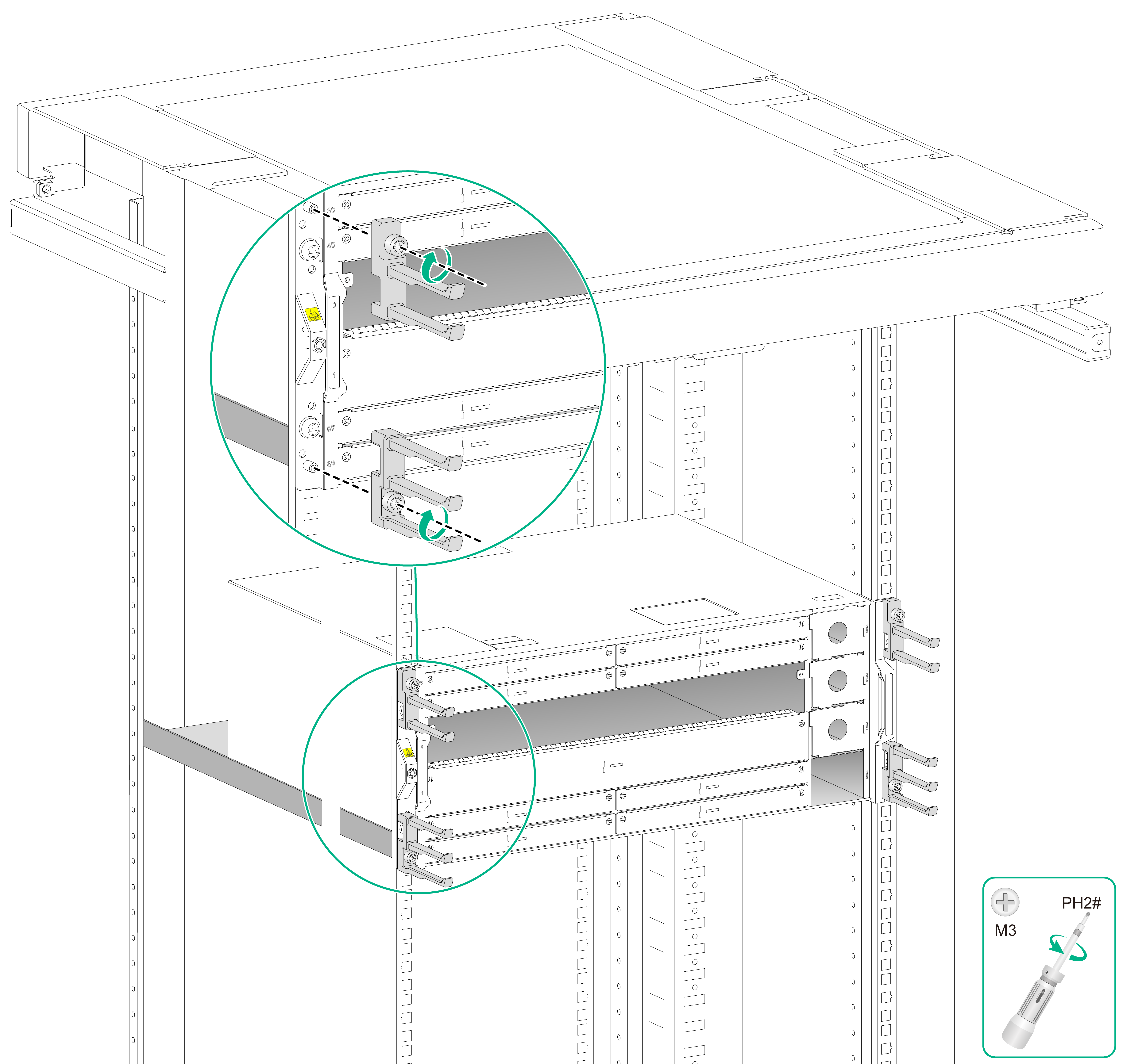

1. Identify the cable management bracket installation positions on the mounting brackets. Attach two-finger cable management brackets to the upper part of the mounting brackets and three-finger cable management brackets to the lower part of the mounting brackets.

2. Align the captive screws on the cable management brackets with the raised screw holes in the mounting brackets, and then fasten the captive screws.

Figure3-3 Installing cable management brackets

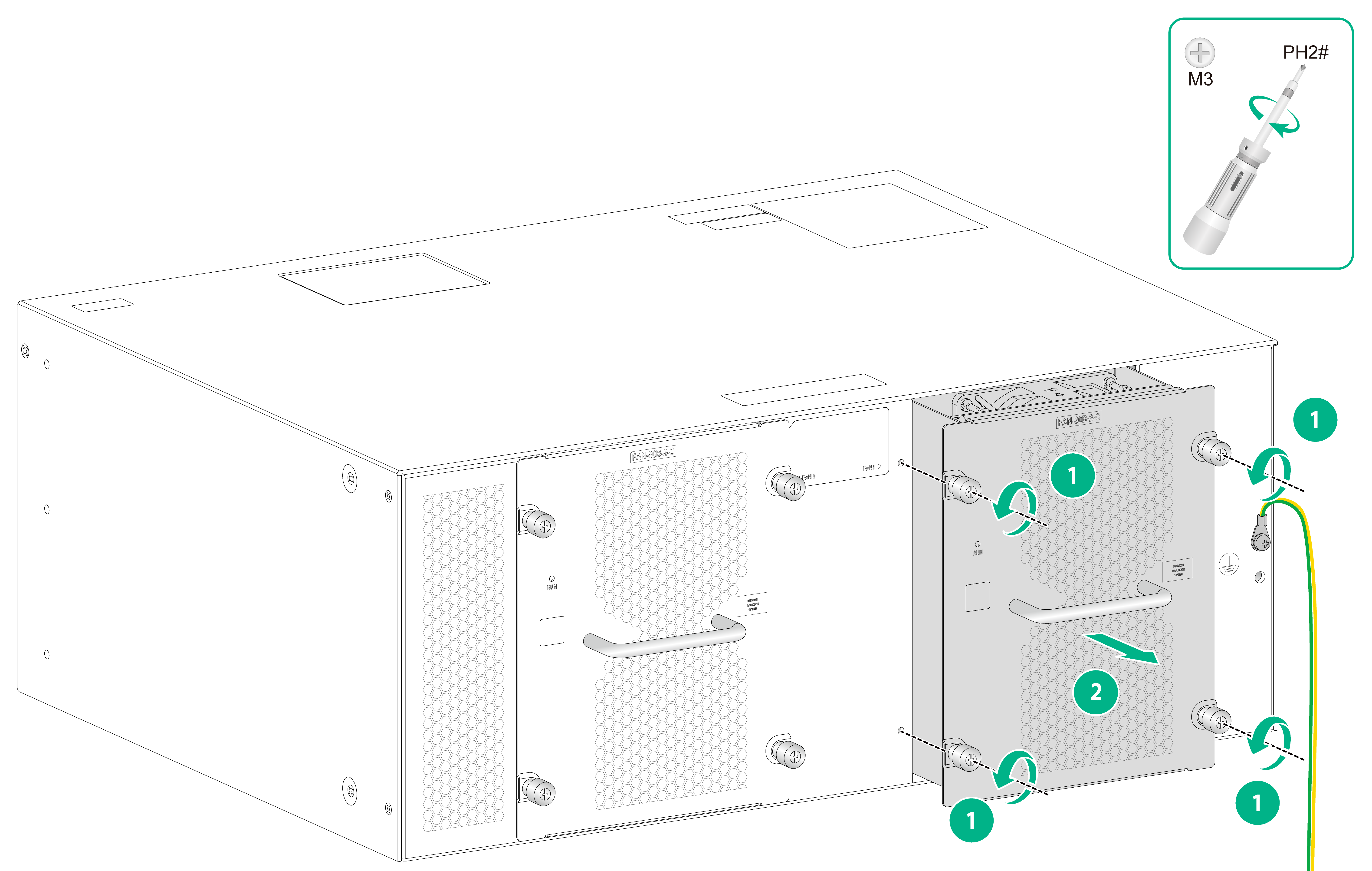

Grounding the router

|

WARNING! · Correctly connecting the grounding cable is crucial to lightning protection and EMI protection. · Do not connect the router grounding cable to a fire main or lightning rod. |

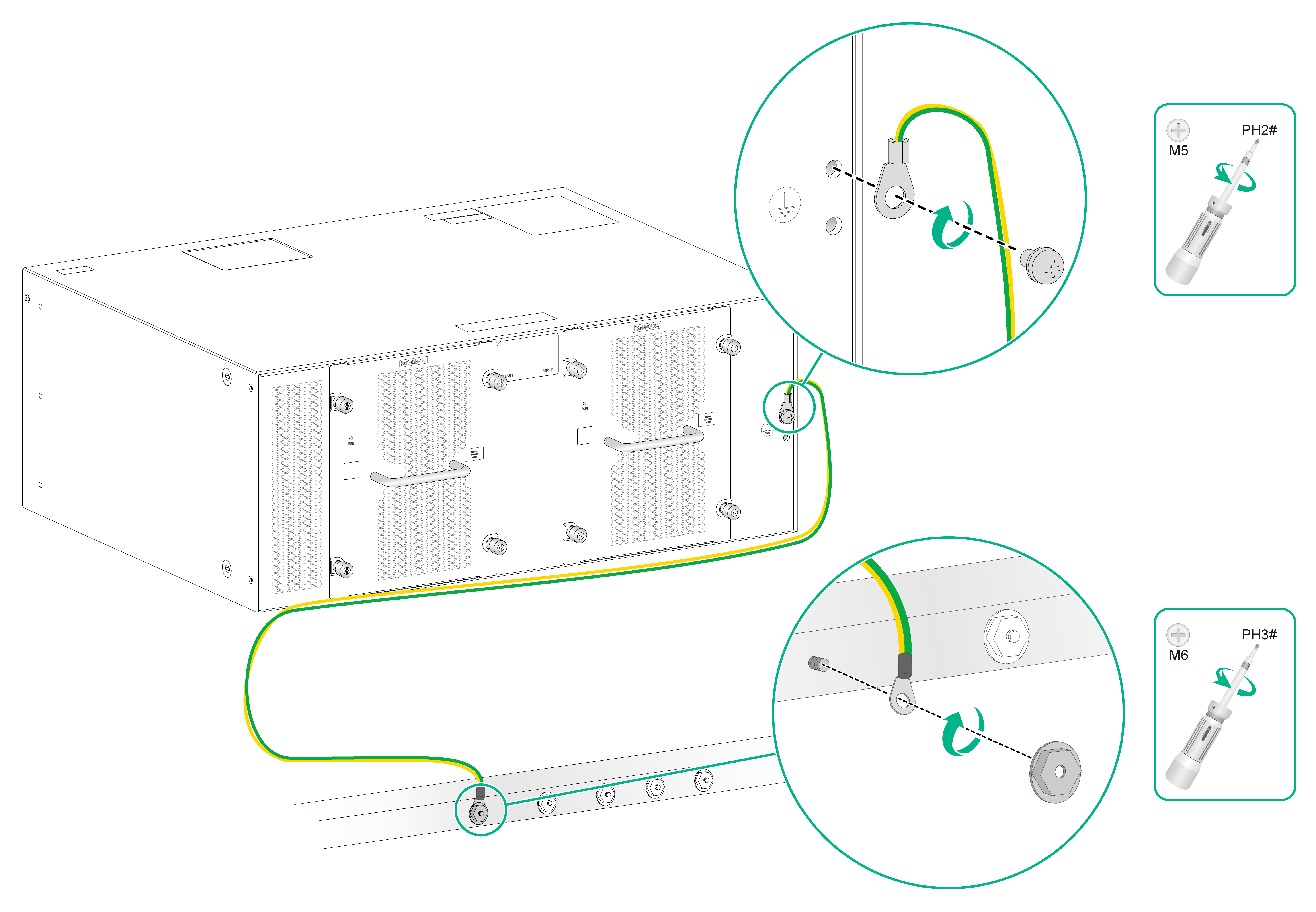

To ground the router:

1. Use a Phillips screwdriver to remove the grounding screw from the router chassis.

2. Attach the grounding screw to the ring terminal of the grounding cable.

3. Use a Phillips screwdriver to fasten the grounding screw into the grounding hole on the router.

4. Connect the other end (ring terminal) of the grounding cable to a grounding strip or a grounding point on the rack.

Figure3-4 Grounding the router

4 Installing removable components

|

CAUTION: · Do not leave any slots empty when the router is operating. Install a module or filler panel in the slots. · Keep the filler panels and the packaging boxes and packaging bags of removable components for future use. · To avoid device damage, do not hold the handle of a power supply or a module to move the router. |

Installing an RFU

|

CAUTION: · Active/standby routing and forwarding unit (RFU) switchover is supported when the router is configured with two RFUs. For the standby RFU to operate correctly, make sure it is the same model as the active RFU. · The RFUs are hot swappable. To hot swap an RFU with a storage medium, first execute the umount command to unmount the file system. Remove the RFU only after the system prompts that the file system is unmounted successfully. · To ensure smooth insertion when you install two adjacent RFUs vertically, press down the ejector levers on the latter RFU before pushing it into the slot slowly. |

To install an RFU:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Push the RFU gently into the slot along the guide rails, and then close the ejector levers.

3. Use a Phillips screwdriver to fasten the two captive screws on the RFU to secure the RFU to the router.

Figure4-1 Installing an RFU

Install an HMIC interface module

|

CAUTION: · The HMIC interface modules without a remove button can be hot swapped. To remove an HMIC interface module with a remove button (except for the RT-HMIC-CQ1F, which can be hot swapped) while the router is operating, first press the remove button until the RUN LED on the interface module is off. For more information about hot swapping of interface modules, see H3C SR6608-M Router Interface Module User Guide. · Do not install an HMIC interface module during an active/standby RFU switchover. To view the RFU status, execute the display system stable state command in any view. · To ensure smooth insertion when you install two adjacent HMIC interface modules vertically, press down the ejector levers on the latter HMIC interface module before pushing it into the slot slowly. |

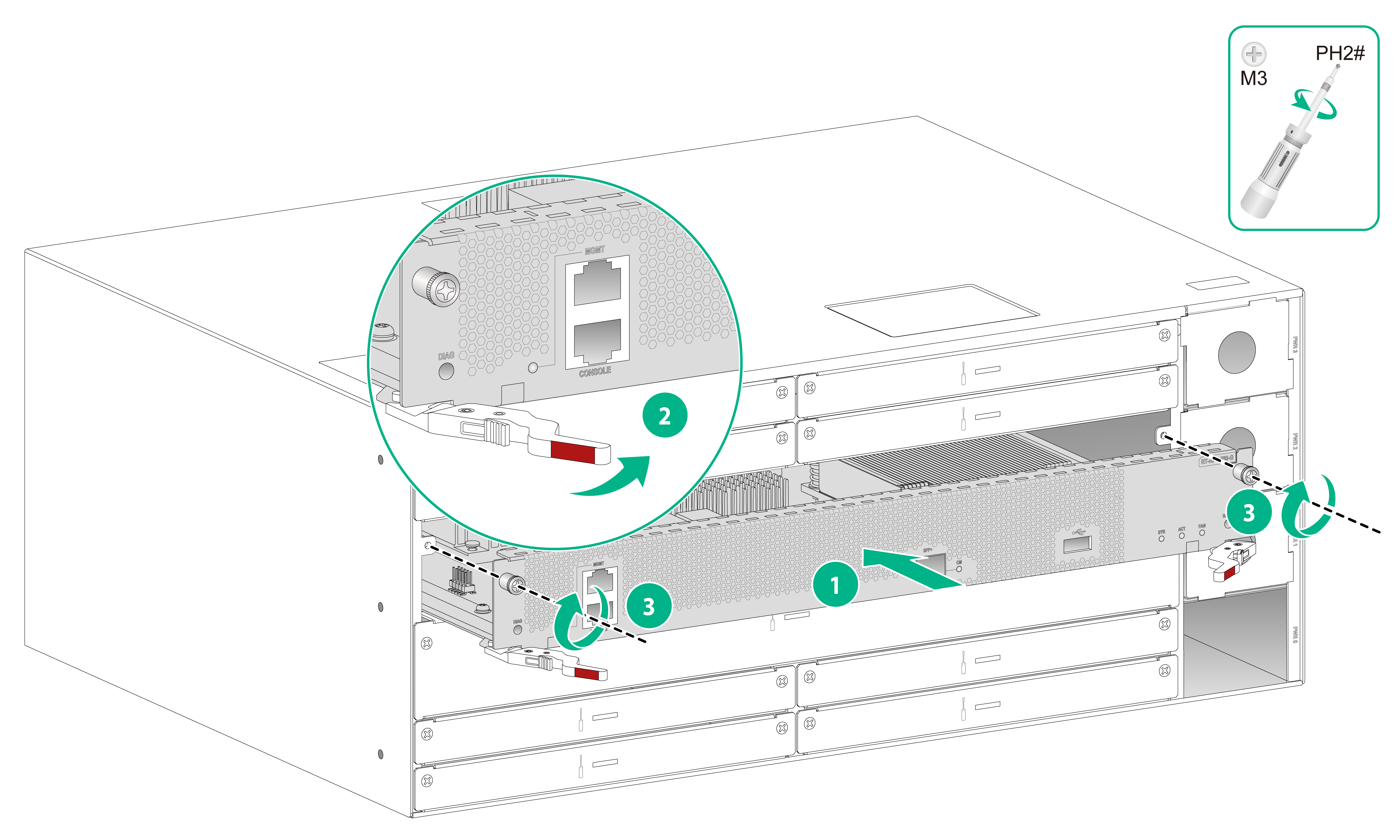

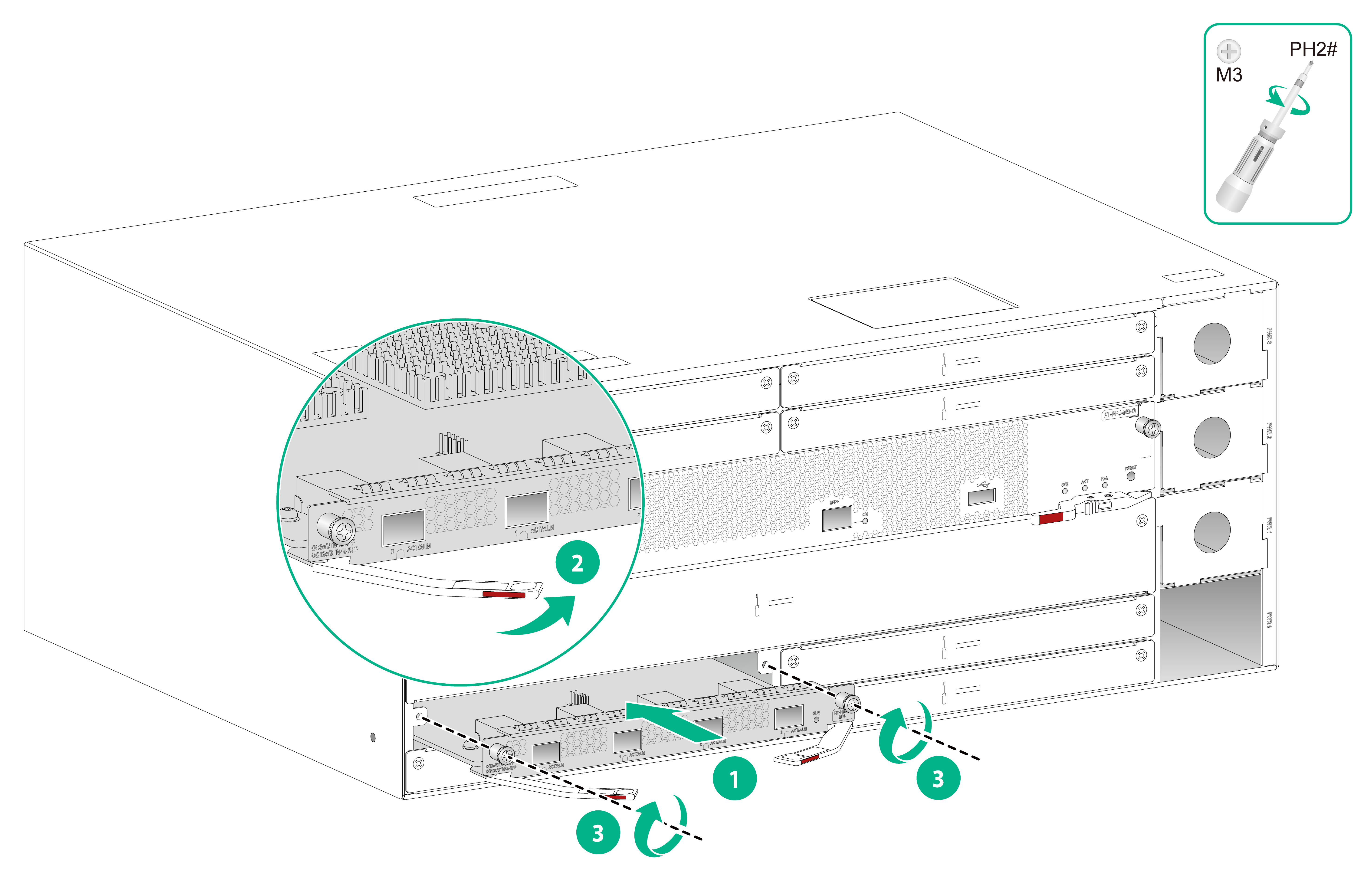

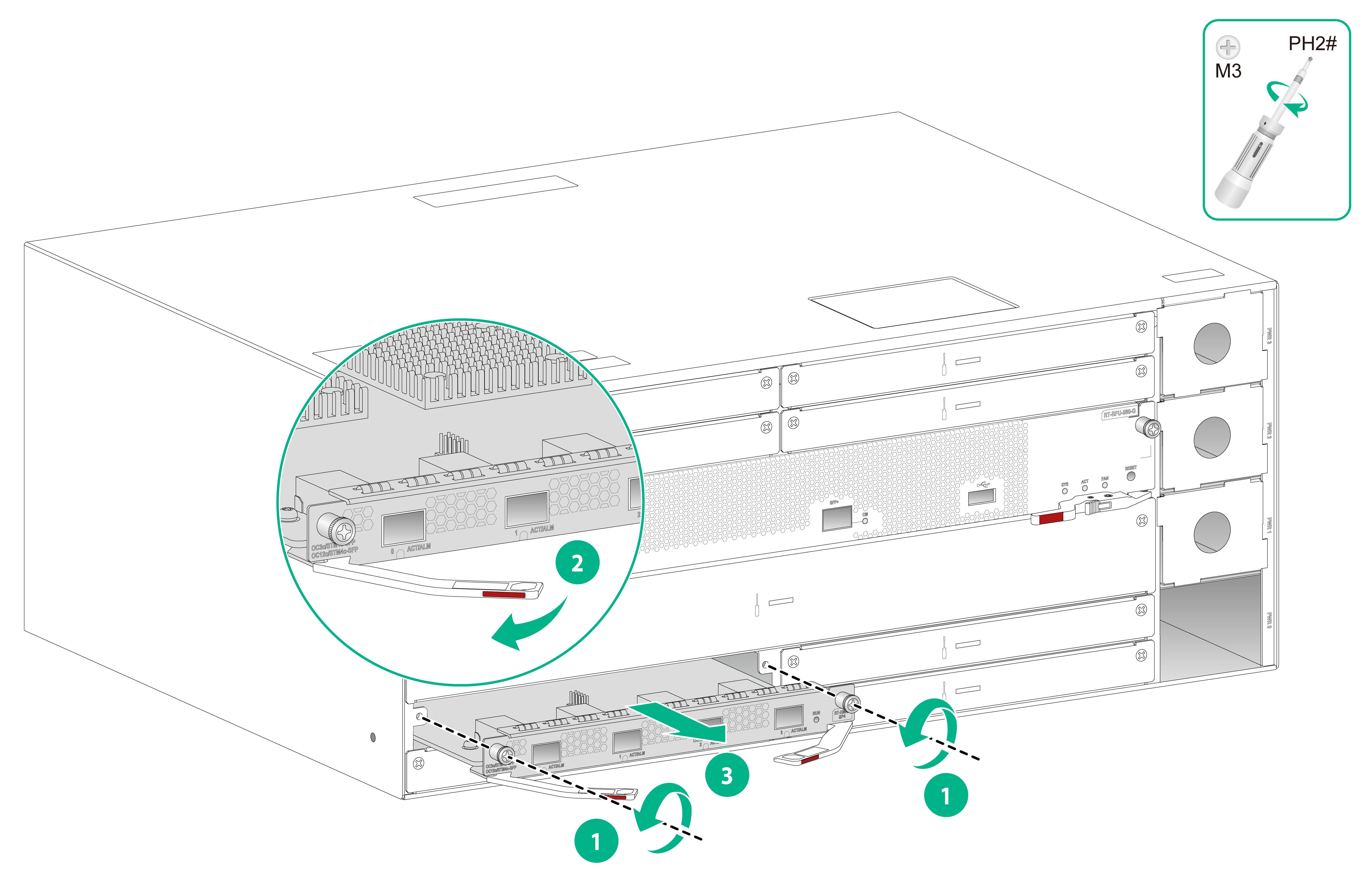

To install an HMIC interface module:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Use a Phillips screwdriver to remove the fastening screws on the filler panel. Then, feed the tip of a flat-head screwdriver through the hole on the filler panel, and pull the filler panel outwards to remove the filler panel. Keep the removed filler panel secure for future use.

3. Pull outward the two ejector levers of the module and then push the module slowly into the slot along the guide rails.

4. Push inward the two ejector levers to ensure that the interface module is firmly seated in the slot.

5. Use a Phillips screwdriver to fasten the captive screws on the interface module.

Figure4-2 Installing an HMIC interface module

Installing a power supply and connecting the power cord

|

WARNING! Provide a separate circuit breaker for each power supply. |

|

CAUTION: · The router supports only mix of 450 W AC and DC power supplies. · Do not install AC and DC power supplies on the same router. · To prevent damage to the connectors inside the chassis, insert the power supply gently. If you encounter a hard resistance while inserting the power supply, pull out the power supply and insert it again. |

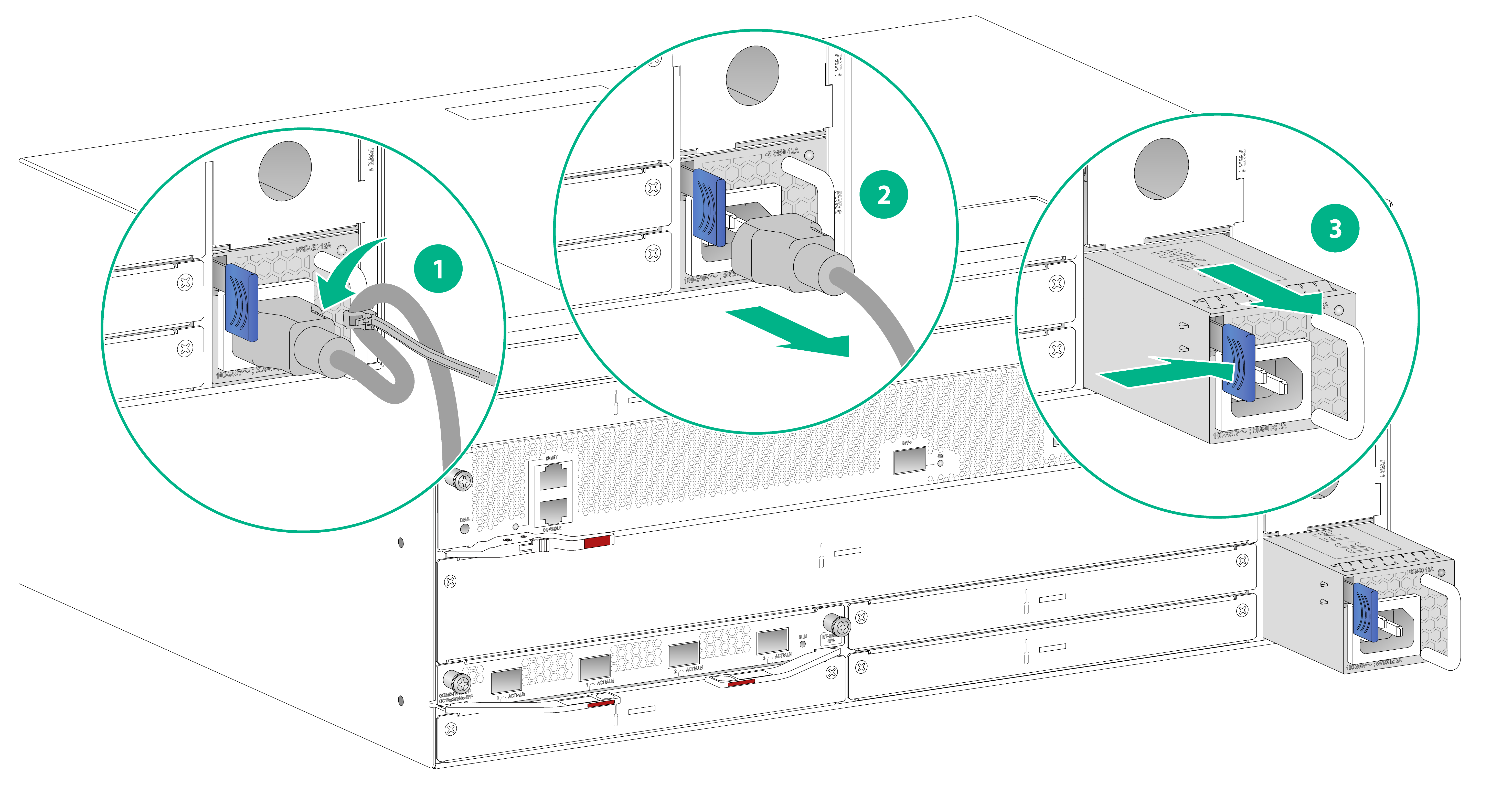

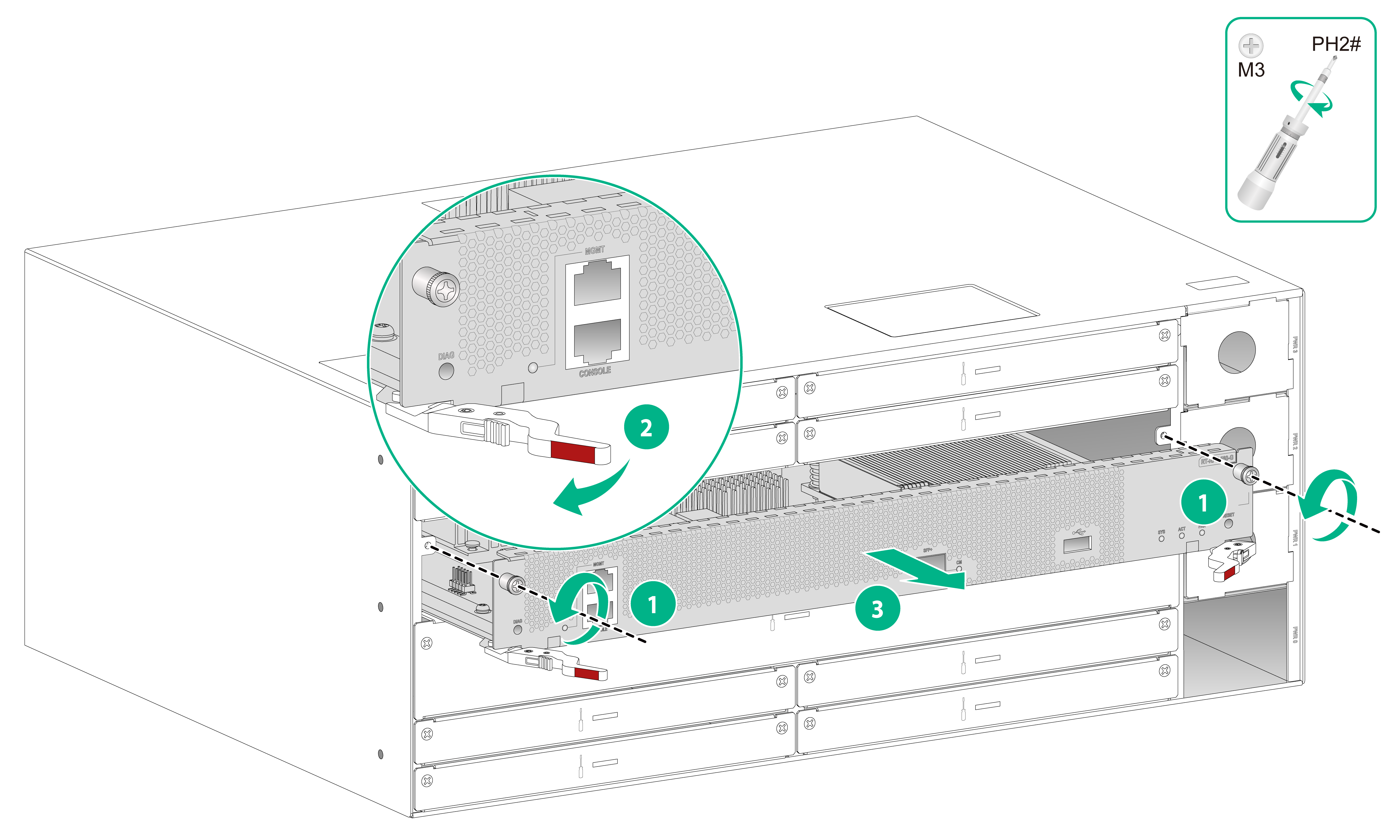

To avoid device damage or bodily injury, install a power supply as shown in Figure4-3.

Figure4-3 Installation procedure

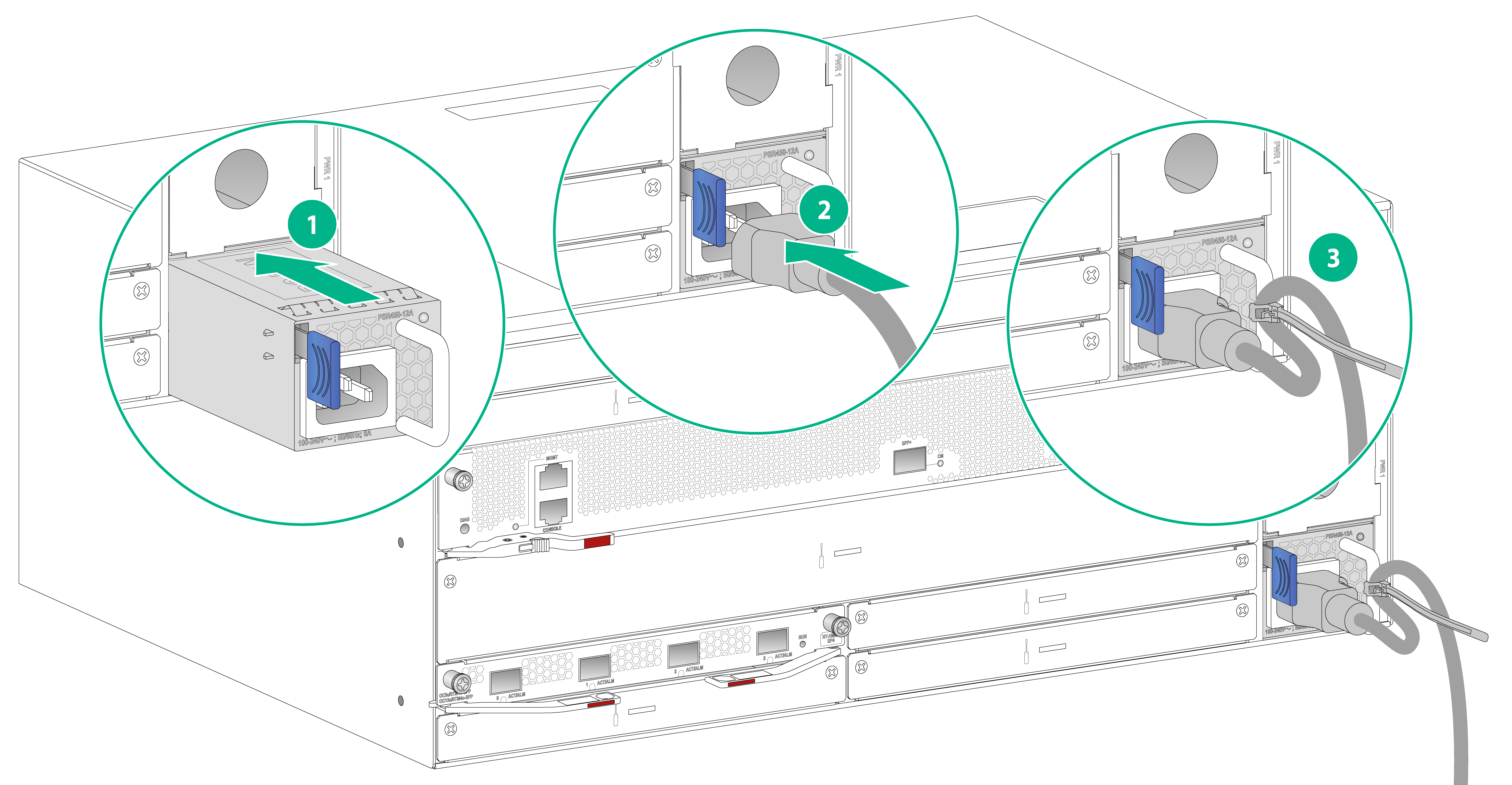

Installing an AC power supply and connecting the power cord

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Unpack the power supply and verify that the power supply model is correct.

3. Correctly orient the power supply with the power supply slot. Insert the power supply slowly into the slot along the guide rails until it clicks into place.

4. Insert the female connector of the power cord into the AC power receptacle on the power supply.

5. Use a cable tie to secure the power cord to the handle of the power supply.

6. Connect the other end of the power cord to an AC power source.

Figure4-4 Installing an AC power supply and connecting the power cord

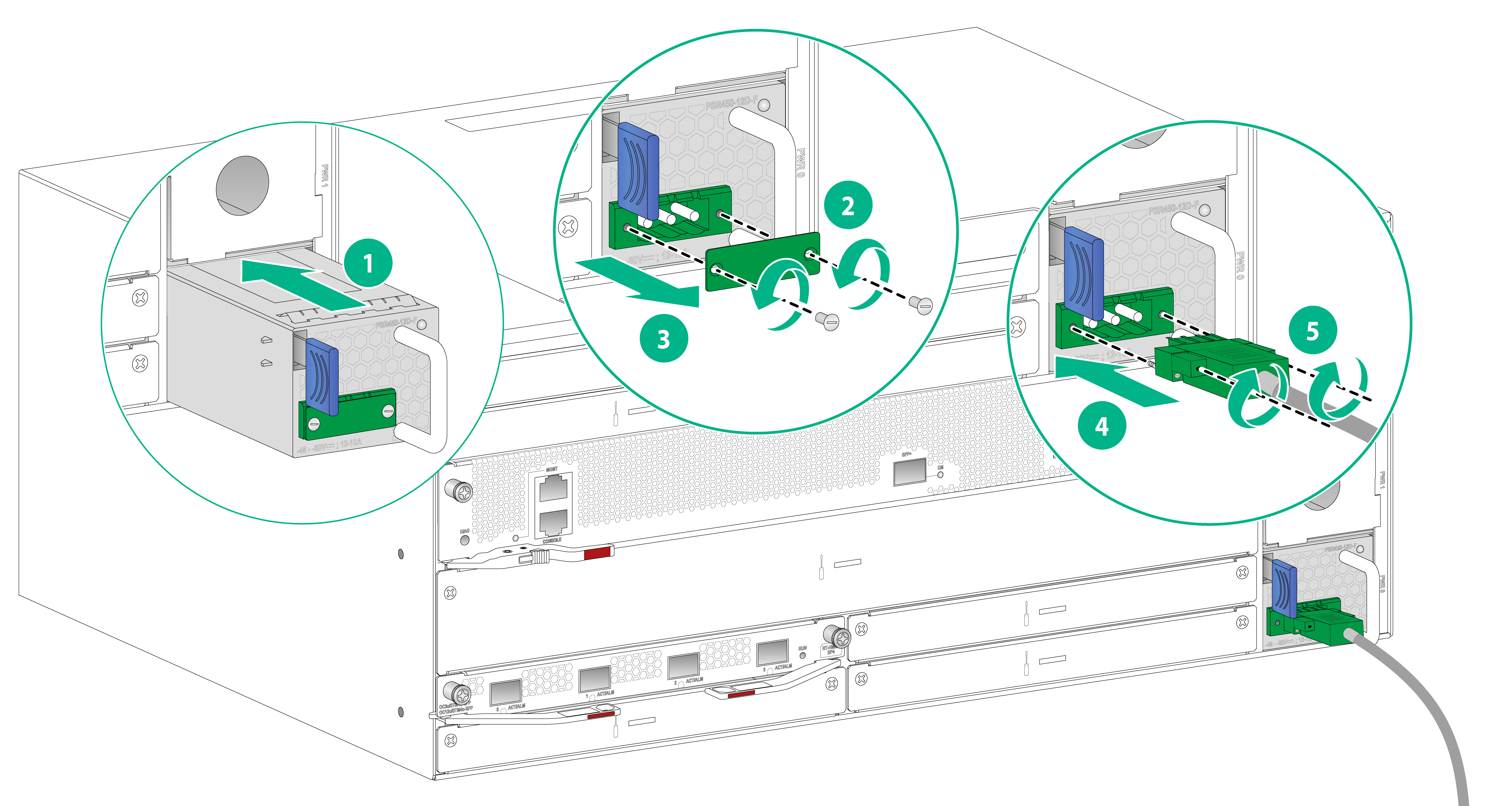

Installing a DC power supply and connecting the power cord

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Unpack the power supply and verify that the power supply model is correct.

3. Correctly orient the power supply. Insert the power supply slowly into the slot along the guide rails until it clicks into place.

4. Use a flat-head screwdriver to loosen the screws on the protective plate over the DC power receptacle, and then remove the plate.

5. Correctly orient the DC power cord connector and insert it into the power receptacle.

The DC power cord connector and DC power receptacle form an anti-misinsertion structure. If you orient the DC power cord connector upside down, you cannot insert it into the receptacle.

6. Use a flat-head screwdriver to fasten the screws on the power cord connector to secure the connector to the power receptacle.

7. Connect the other end of the DC power cord to the wiring terminals of a DC power source, with the negative wire (–) to the negative terminal (–) and the positive wire (+) to the positive terminal (+).

Figure4-5 Installing a DC power supply and connecting the power cord

5 Connecting cables

Connecting copper Ethernet cables

Auto-MDI/MDIX is supported on the Ethernet copper ports on the front panel of the router and the 10/100/1000BASE-T ports on the interface modules. You can use straight-through or cross-over network cables to connect the copper Ethernet ports.

To connect a copper Ethernet cable:

1. Connect one end of the Ethernet cable to a copper Ethernet port on the router, and the other end of the cable to the peer Ethernet port.

2. Examine the LED for the Ethernet port to verify that the port is operating correctly. For more information about the LEDs, see H3C SR6608-M Router Hardware Information and Specifications.

|

|

NOTE: After connecting the router to the network, you can use the ping or tracert command to verify network connectivity of the router. For more information about the commands, see the command references for the router. |

Connecting optical fibers

|

WARNING! Disconnected optical fibers or transceiver modules might emit invisible laser light. Do not stare into beams or view directly with optical instruments when the device is operating. |

|

CAUTION: · Never bend an optical fiber excessively. The bend radius of an optical fiber must be not less than 100 mm (3.94 in). · Keep the fiber end clean. · To connect an optical fiber to a fiber port, make sure the fiber connector matches the transceiver module. · Before connecting an optical fiber, make sure the received optical power does not exceed the upper receive power threshold of the transceiver module. If the threshold is exceeded, the transceiver module might be damaged. · To connect an optical fiber to a fiber port, first install a transceiver module in the fiber port and then connect the optical fiber to the transceiver module. · Insert a dust plug into any open fiber port. |

To connect an optical fiber:

1. Remove the dust plug from the fiber port.

2. Pivot the clasp of the transceiver module up to catch the clip on the top. Hold the two sides of the transceiver module and insert it slowly into the fiber port.

3. Remove the dust cap from the optical fiber connector, and use dust-free paper and absolute ethanol to clean the end face of the fiber connector.

4. Identify the Rx and Tx ports on the transceiver module. Use the optical fiber to connect the Rx port and the Tx port on the transceiver module to the Tx port and the Rx port on the peer router, respectively.

Figure5-1 Connecting a transceiver module and optical fiber

6 Verifying the installation

After the installation is completed, verify the following items:

· There is enough space around the router for heat dissipation.

· The rack or workbench is stable.

· The grounding cable is correctly and securely connected.

· The power supplies are compatible with the router, and the power source is as required by the router.

· The power cords are correctly connected.

· If part of the network cable for a port is routed outdoors, verify that a network port lightning protector is used for the port.

· If a power line is routed from outdoors, verify that a surge protected power strip is used for the router.

7 Accessing the router for the first time

To access the router for the first time, use a console cable to connect a console terminal (for example, a PC) to the serial console port on the router.

Connecting the router to a configuration terminal

Console cables

As shown in Table7-1, two types of console cables can be used for connecting a configuration terminal to the console port on the router. No console cable is provided with the router. Purchase a console cable as required.

Table7-1 Console cables for connecting the console port

|

Console cable type |

Console cable view |

Router-side connector |

Configuration terminal-side connector |

|

DB9-to-RJ45 console cable |

DB-9 female connector |

RJ-45 |

|

|

USB-to-RJ45 console cable |

USB |

RJ-45 |

Connecting a DB9-to-RJ45 console cable

|

CAUTION: The serial ports on PCs do not support hot swapping. If the router has been powered on, connect the serial console cable to the PC before connecting to the router, and when you disconnect the cable, first disconnect from the router. |

To connect the router to a configuration terminal by using a serial console cable:

1. Connect the DB-9 female connector of the console cable to the serial port on the configuration terminal.

2. Connect the RJ-45 connector to the console port on the router.

Connecting a USB-to-RJ45 console cable

|

IMPORTANT: · To use a USB-to-RJ45 console cable to connect the router to a configuration terminal, first download and install the USB-to-RJ45 console driver on the configuration terminal, and then connect the USB-to-RJ45 console cable to the configuration terminal. To download the USB-to-RJ45 console driver, access the H3C official website or scan the QR code on the cable package. · If you have connected a USB-to-RJ45 console cable to the configuration terminal before installing the driver, remove and reconnect the USB-to-RJ45 console cable to the configuration terminal after driver installation. |

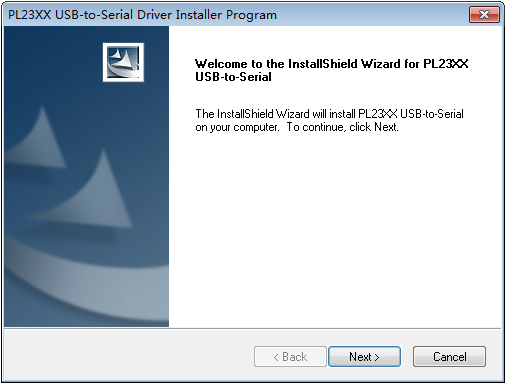

The following installs the driver on the Windows system. To install the driver on other operating systems, see the installation guide in the driver compression package named by using the corresponding operating system.

To connect the router to a configuration terminal by using a USB-to-RJ45 console cable:

1. Click the following link, or copy it to the address bar on your browser and download the USB-to-RJ45 console driver.

http://www.h3c.com/en/home/USB_to_RJ45_Console/

2. View the TXT file Read me in the Windows folder to check whether the Windows system of the configuration terminal supports the driver.

3. If the Windows system supports the driver, install PL23XX-M_LogoDriver_Setup_v200_20190815.exe.

4. Click Next on the welcome page of the driver installation wizard.

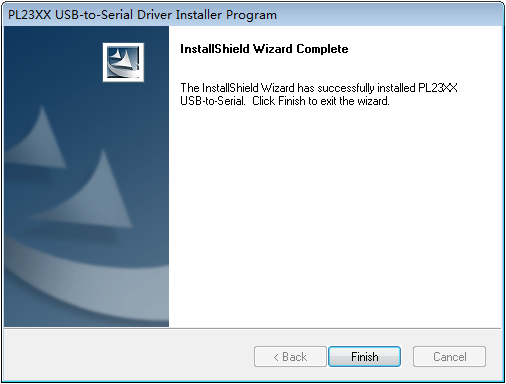

Figure7-1 Driver installation wizard

5. Click Finish after the drive installation is completed.

Figure7-2 Finishing the driver installation

6. Connect the standard USB connector of the cable to the USB port of the configuration terminal.

7. Connect the RJ-45 connector of the cable to the console port of the router.

Setting terminal parameters

To configure and manage the router through the console port, you must run a terminal emulator program, HyperTerminal or PuTTY, on your configuration terminal. You can use the emulator program to connect a network device, a Telnet site, or an SSH site. For more information about the terminal emulator programs, see the user guides for these programs

Configure the terminal parameters as follows:

· Bits per second—9600.

· Data bits—8.

· Stop bits—1.

· Parity—None.

· Flow control—None.

Starting the router

1. Verify that the following conditions are met before powering on the router:

¡ The power cord is correctly connected.

¡ The input power voltage is as required by the router.

¡ The console cable is correctly connected.

¡ The configuration terminal (a PC, for example) has started, and terminal parameters have been configured correctly.

2. Power on the router.

After powering on the router, you can determine whether the router is operating correctly by observing the system status LED (SYS) on the router. If the SYS LED is flashing green at 1 Hz, the router is operating correctly.

During the startup process, you can access Boot ROM menus to perform tasks such as software upgrade and file management. The Boot ROM interface and menu options vary by software version. For more information about Boot ROM menu options, see the release notes for the specific software version.

3. Examine the LEDs on the router to verify that the router is operating correctly. If the RUN LED is flashing green at 1 Hz, the router is operating correctly. For more information about the LEDs, see H3C SR6608-M Router Hardware Information and Specifications.

4. Access the CLI to configure the router.

For more information about the configuration commands, see the configuration guides and command references for the router.

8 Replacing removable components

Replacing a power supply

|

WARNING! To avoid device damage or bodily injury, strictly follow the removal procedure in Figure8-1 to remove a power supply. |

Figure8-1 Power supply removal procedure

|

CAUTION: For adequate heat dissipation and dust prevention, install a filler panel in a power supply slot if you are not to install a new power supply in the slot after removing the old one. |

The replacement procedure is similar for AC and DC power supplies. This section uses the AC power supply as an example.

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Remove the power cord from the power supply.

3. Pressing the latch on the power supply towards the handle direction, pull the power supply slowly out of the slot.

4. Place the removed power supply on an antistatic mat.

5. Install a new power supply in the slot. For the installation procedure, see "Installing a power supply."

If you are no to install a new power supply, install a filler panel in the slot.

Figure8-2 Removing a power supply

Replacing a fan tray

|

WARNING! · Ensure electricity safety when replacing a fan tray during router operation. · To avoid injury, do not touch the rotating fan blades. |

|

CAUTION: · To avoid disturbing the dynamic balance of a fan tray and causing loud noises, do not touch the fan blades and rotation axis even if the fan tray stops rotating. · When a fan tray fails during router operation, replace the fan tray immediately. Keep the failed fan tray in position until you start the replacement. · When an internal circuit or component of a fan tray is faulty, contact H3C Support for repair. Do not remove the components yourself. |

To replace a fan tray:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Use a Phillips screwdriver to loosen the captive screws on the fan tray.

3. Holding the handle of the fan tray with one hand and supporting its bottom with the other, gently pull out the fan tray from the fan tray slot along the guide rails.

4. Replace the removed fan tray on an antistatic mat.

5. Install a new fan tray. Holding the fan tray handle, push the fan tray into the slot along the guide rails. Fasten the captive screws on the fan tray.

Replace an HMIC interface module

|

CAUTION: You can hot swap an HMIC interface module only when the RUN LED on the module is steady green. |

To replace an HMIC interface module:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Use a Phillips screwdriver to loosen the captive screws on the interface module.

3. Pull outward the two ejector levers of the module and then pull out the module slowly from the slot along the guide rails.

4. Place the removed HMIC Interface on an antistatic mat.

Figure8-4 Removing an HMIC interface module

5. Install a filler panel in the slot if you are not to install a new HMIC interface module. To install a new HMIC interface module, follow the procedure described in "Install an HMIC interface module."

Replacing an RFU

|

CAUTION: The RFUs are hot swappable. To hot swap an RFU with a storage medium, first execute the umount command to unmount the file system. Remove the RFU only after the system prompts that the file system is unmounted successfully. |

To replace an RFU:

1. Wear an ESD wrist strap and make sure the strap makes good skin contact and is reliably grounded.

2. Use a Phillips screwdriver to loosen the captive screws on the RFU.

3. Pull outward the two ejector levers of the module and then pull out the module slowly out of the slot along the guide rails.

4. Place the removed module on an antistatic mat.

Figure8-5 Removing an RFU

5. Install a filler panel in the slot if you are not to install a new RFU. To install a new RFU, follow the procedure described in "Installing an RFU."

9 Hardware management and maintenance

The command lines and outputs vary by software version. For more information about the command lines and their outputs, see the command references for the specific software version.

Displaying software and hardware version information for the router

Use the display version command to display software and hardware version information for the router. This command also displays the system running time and the type and running time of each module.

<Sysname> display version

Displaying the operational statistics about the router

During daily maintenance or when a fault occurs, you need to view the running information of each functional module to locate the issue.

You can use one of the following methods to collect operating statistics for diagnostics and troubleshooting:

· Use separate display commands, such as display clock, display version, display device, and display current-configuration to collect operating information feature by feature or module by module.

· Use the display diagnostic-information command to save or display operating information for multiple or all features and hardware modules.

¡ Save operating information for multiple or all features and hardware modules:

<Sysname> display diagnostic-information

Save or display diagnostic information (Y=save, N=display)? [Y/N]:y

Please input the file name(*.tar.gz)[flash:/diag_360_20220803-063834.tar.gz]:diag.tar.gz

Diagnostic information is outputting to flash:/diag.tar.gz.

Please wait...

Save successfully.

To save storage space, this command automatically compresses the information before saving the information to a file. To view the file content:

# Use the tar extract archive-file command to extract the file.

# Use the gunzip command to decompress the extracted file.

# Use the more command to view the content of the decompressed file.

¡ Save operating information for multiple or all features and hardware modules:

<Sysname> display diagnostic-information

Save or display diagnostic information (Y=save, N=display)? [Y/N]:n

===============================================

===============display clock===============

14:03:55 UTC Thu 01/05/2023

=================================================

===============display version===============

…

Displaying detailed information about the router

Use the display device verbose command to display detailed information about the router and the modules.

<Sysname> display device verbose

Slot No. Board type Status Primary SubSlots

----------------------------------------------------------------

0 RT-RFU-360-G Normal Standby 0

1 RT-RFU-360-G Normal Master 0

2 RT-HMIC-GT8 Normal N/A 0

3 RT-HMIC-GT8 Normal N/A 0

4 N/A Absent N/A N/A

5 N/A Absent N/A N/A

6 N/A Absent N/A N/A

7 N/A Absent N/A N/A

8 N/A Absent N/A N/A

9 N/A Absent N/A N/A

Slot 0: RT-RFU-360-G

Subslot No. Board Type Status Max Ports

------------------------------------------------------------

0 Fixed SubCard on Board Normal 3

Slot 1: RT-RFU-360-G

Subslot No. Board Type Status Max Ports

-------------------------------------------------------------

0 Fixed SubCard on Board Normal 3

Slot 2: RT-HMIC-GT8

Subslot No. Board Type Status Max Ports

-------------------------------------------------------------

0 Fixed SubCard on Board Normal 8

Slot 3: RT-HMIC-GT8

Subslot No. Board Type Status Max Ports

-------------------------------------------------------------

0 Fixed SubCard on Board Normal 8

Slot 0: RT-RFU-360-G

Subslot 0

Status: Normal

Type: Fixed SubCard on Board

Hardware: Ver.7

Driver: 1.0

CPLD: 1.0

Slot 1: RT-RFU-360-G

Subslot 0

Status: Normal

Type: Fixed SubCard on Board

Hardware: Ver.7

Driver: 1.0

CPLD: 1.0

Slot 2: RT-HMIC-GT8

Subslot 0

Status: Normal

Type: Fixed SubCard on Board

Hardware: Ver.A

Driver: 1.0

CPLD: 193.0

Slot 3: RT-HMIC-GT8

Subslot 0

Status: Normal

Type: Fixed SubCard on Board

Hardware: Ver.A

Driver: 1.0

CPLD: 1.0

Use the display device slot slot-number command to display detailed information about a module.

<Sysname> display device slot 1

Slot 1: RT-RFU-360-G

Subslot No. Board Type Status Max Ports

-------------------------------------------------------------

0 Fixed SubCard on Board Normal 3

Table9-1 Command output

|

Field |

Description |

|

Slot No |

Slot number. |

|

Board Type |

Hardware type of the module. |

|

Status |

Module status: · Absent—The slot is empty. · Fault—The module in the slot is faulty and cannot start up. · Normal—The module is operating correctly. |

|

Primary |

Role of the module. · Master—The module is the active RFU. · Standby—The module is the standby RFU. |

|

Max Ports |

Number of ports on the module. |

Displaying electrical label information for the router

Use the display device manuinfo command to display electrical label information for the router.

An electronic label contains the permanent configuration information, including the name, hardware serial number, manufacturing date, MAC address, and vendor name of the router and modules.

<Sysname> display device manuinfo

Chassis self:

DEVICE_NAME:SR6608-M

DEVICE_SERIAL_NUMBER:219801XX11X199000001

MAC_ADDRESS:0020-E212-3451

MANUFACTURING_DATE:2019-09-18

VENDOR_NAME:H3C

Slot 0 CPU 0:

DEVICE_NAME:RT-RFU360-G

DEVICE_SERIAL_NUMBER:219801XXX1X199000001

MAC_ADDRESS:0020-E212-3451

MANUFACTURING_DATE:2019-09-18

VENDOR_NAME:H3C

Slot 1 CPU 0:

DEVICE_NAME:RT-RFU360-G

DEVICE_SERIAL_NUMBER:219801XXX1X199000001

MAC_ADDRESS:0020-E212-3451

MANUFACTURING_DATE:2019-09-18

VENDOR_NAME:H3C

Slot 2:

DEVICE_NAME:RT-HMIC-GT8

DEVICE_SERIAL_NUMBER:210231AK61X199000001

MAC_ADDRESS:000F-E212-3451

MANUFACTURING_DATE:2022-09-18

VENDOR_NAME:H3C

Slot 3:

DEVICE_NAME:RT-HMIC-GT8

DEVICE_SERIAL_NUMBER:210231AK61X199000001

MAC_ADDRESS:000F-E212-3451

MANUFACTURING_DATE:2022-09-18

VENDOR_NAME:H3C

Use the display device manuinfo slot slot-number command to display electrical label information for a module.

<Sysname> display device manuinfo slot 1

Slot 1 CPU 0:

DEVICE_NAME:RT-RFU360-G

DEVICE_SERIAL_NUMBER:219801XXX1X199000001

MAC_ADDRESS:0020-E212-3451

MANUFACTURING_DATE:2019-09-18

VENDOR_NAME:H3C

Table9-2 Command output

|

Field |

Description |

|

DEVICE_NAME |

Name of the device or module. |

|

DEVICE_SERIAL_NUMBER |

Serial number of the device or module. |

|

MAC_ADDRESS |

MAC address of the device or module. |

|

MANUFACTURING_DATE |

Manufacturing date of the device or module. |

|

VENDOR_NAME |

Vendor name of the device or module. |

Displaying the CPU usage of the router

Use the display cpu-usage command to display the CPU usage of the router.

<Sysname> display cpu-usage

Slot 1 CPU 0 CPU usage:

38% in last 5 seconds

38% in last 1 minute

40% in last 5 minutes

Table9-3 Output description

|

Field |

Description |

|

38% in last 5 seconds |

Average CPU usage in the most recent 5 seconds. (After the router boots, the router calculates and records the average CPU usage at intervals of 5 seconds.) |

|

38% in last 1 minute |

Average CPU usage in the most recent minute. (After the router boots, the router calculates and records the average CPU usage at intervals of 1 minute.) |

|

40% in last 5 minutes |

Average CPU usage in the most recent 5 minutes. (After the router boots, the router calculates and records the average CPU usage at intervals of 5 minutes.) |

Displaying the memory usage of the router

Use the display memory command to display memory usage of the router.

Memory statistics are measured in KB:

Slot 0:

Total Used Free Shared Buffers Cached FreeRatio

Mem: 7991828 4042780 3949048 0 1776 1221876 49.8%

-/+ Buffers/Cache: 2819128 5172700

Swap: 0 0 0

Slot 1:

Total Used Free Shared Buffers Cached FreeRatio

Mem: 7991828 3820996 4170832 0 496 1206524 52.3%

-/+ Buffers/Cache: 2613976 5377852

Swap: 0 0 0

Container memory statistics are measured in KB:

Slot 0:

Total Used Free UsageRatio

Mem: 7991828 1555164 3948860 19.5%

Slot 1:

Total Used Free UsageRatio

Mem: 7991828 1351724 4170832 16.9%

Table9-4 Command output

|

Field |

Description |

|

Memory statistics are measured in KB |

Memory usage information. |

|

Total |

Total size of the physical memory space that can be allocated. The memory space is virtually divided into two parts. Part 1 is used for kernel codes, kernel management, and ISSU functions. Part 2 can be allocated and used for such tasks as running service modules and storing files. The size of part 2 equals the total size minus the size of part 1. |

|

Used |

Used physical memory. |

|

Free |

Free physical memory. |

|

Shared |

Physical memory shared by processes. If this field is not supported, two hyphens (--) are displayed. |

|

Buffers |

Physical memory used for buffers. If this field is not supported, two hyphens (--) are displayed. |

|

Cached |

Physical memory used for caches. If this field is not supported, two hyphens (--) are displayed. |

|

FreeRatio |

Free memory ratio. |

|

-/+ Buffers/Cache |

-/+ Buffers/Cache:used = Mem:Used – Mem:Buffers – Mem:Cached, which indicates the physical memory used by applications. -/+ Buffers/Cache:free = Mem:Free + Mem:Buffers + Mem:Cached, which indicates the physical memory available for applications. |

|

Swap |

Swap memory. |

|

Container memory statistics are measured in KB |

· Total—Physical memory allocable to Comware containers, in KB. · Used—Physical memory used by Comware containers, in KB. · Free—Free physical memory available for Comware containers, in KB. · UsageRatio—Comware container memory usage ratio. |

Displaying the operational status of fan trays

Use the display fan command to display the operational status of fan trays.

<Sysname> display fan

Fan No. State Speed

---------------------------

0 Normal 50

1 Absent N/A

Table9-5 Command output

|

Field |

Description |

|

Fan No |

Slot number of the fan tray. |

|

State |

State of the fan tray: · Normal—The fan tray is operating correctly. · Absent—No fan tray is present. · Fault—The fan tray is faulty. |

|

Speed |

Speed of the fan tray, in percentage to the maximum speed. |

Displaying the operational status of power supplies

Use the display power-supply command to display the operational status of power supplies.

<Sysname> display power-supply

PWR No. State

-----------------

0 Absent

1 Absent

2 Normal

3 Absent

Table9-6 Command output

|

Field |

Description |

|

Power No |

Slot number of the power supply. |

|

State |

State of the power supply: · Normal—The power supply is operating correctly. · Absent—No power supply is present. · Fault—The power supply is faulty. |

Displaying temperature information for the router

Use the display environment command to display router temperature information.

<Sysname> display environment

System temperature information (degree centigrade):

---------------------------------------------------------------------------

Slot Sensor Temperature LowerLimit WarningLimit AlarmLimit ShutdownLimit

0 Inflow 1 37 -5 62 67 127

0 Hotspot 1 48 0 68 73 127

0 Hotspot 2 65 0 87 90 127

0 Hotspot 3 60 0 100 117 122

0 Hotspot 4 62 0 100 117 122

0 Hotspot 5 53 0 80 92 97

1 Inflow 1 38 -5 62 67 127

1 Hotspot 1 47 0 68 73 127

1 Hotspot 2 64 0 87 90 127

1 Hotspot 3 57 0 100 117 122

1 Hotspot 4 52 0 100 117 122

1 Hotspot 5 50 0 80 92 97

Table9-7 Command output

|

Field |

Description |

|

System Temperature information (degree centigrade) |

Temperature information (°C). |

|

Sensor |

Temperature sensor: · hotspot—Hotspot sensor. · inflow—Air inlet sensor. · outflow—Air outlet sensor. |

|

Temperature |

Current temperature. |

|

LowerLimit |

Lower temperature limit. If the router does not support this field, this field displays NA. |

|

WarningLimit |

Warning temperature threshold. If the router does not support this field, this field displays NA. |

|

AlarmLimit |

Alarming temperature threshold. If the router does not support this field, this field displays NA. |

|

ShutdownLimit |

Shutdown temperature threshold. When the sensor temperature reaches the limit, the system shuts down automatically. If the router does not support this field, this field displays NA. |

Displaying transceiver module information

Use the display transceiver interface command to display the key parameters of transceiver modules, including the transceiver module type, connector type, central wavelength of the transmit laser, signal transmission distance, and vendor name.

To display transceiver module information:

|

Task |

Command |

Remarks |

|

Display key parameters of transceiver modules. |

display transceiver interface [ interface-type interface-number ] |

Available for all transceiver modules. |

Diagnosing transceiver modules

The router provides the alarm and digital diagnosis functions for transceiver modules. When a transceiver module fails or is not operating correctly, you can perform the following tasks:

· Check the alarms on the transceiver module to identify the fault source.

· Examine the key parameters monitored by the digital diagnosis function, including the temperature, voltage, laser bias current, TX power, and RX power.

To diagnose a transceiver module:

|

Task |

Command |

Remarks |

|

Display transceiver alarms. |

display transceiver alarm interface [ interface-type interface-number ] |

Available for all transceiver modules. |

For more information about transceiver module-rated commands, see the command references for the router.

Saving the running configuration

|

IMPORTANT: You must save the running configuration to a .cfg configuration file. |

You can use one of the following methods to save the running configuration:

· Fast mode—Use the save command without the safely keyword. In this mode, the router directly overwrites the target next-startup configuration file. If a reboot or power failure occurs during this process, the next-startup configuration file is lost. You must specify a new startup configuration file after the router reboots.

· Safe mode—Use the save command with the safely keyword. Safe mode is slower than fast mode, but more secure. In safe mode, the system saves the configuration in a temporary file and starts overwriting the target next-startup configuration file after the save operation is complete. If a reboot or power failure occurs during the save operation, the next-startup configuration file is still retained. Use the safe mode if the power source is not reliable or you are remotely configuring the router.

To save the running configuration:

|

Task |

Command |

Remarks |

|

Save the running configuration to a configuration file, without specifying the file as a next-startup configuration file. |

save file-url [ all | slot slot-number ] |

Use either approach. Available in user view. |

|

Save the running configuration to a configuration file in the root directory of the storage medium, and specify the file as a next-startup configuration file. |

save [ safely ] |

Rebooting the router or a module

|

CAUTION: · If the main system software image file does not exist, do not use the reboot command to reboot the router. Specify the main system software image file first, and then reboot the router. · The precision of the rebooting timer is 1 minute. 1 minute before the rebooting time, the router prompts "REBOOT IN ONE MINUTE" and reboots in one minute. · If you are performing file operations when the router is to be rebooted, the system does not execute the reboot command for security. |

To reboot the router or a module, use one of the following methods:

· Reboot the router at the CLI.

¡ Reboot the router immediately by using the reboot command.

¡ Schedule a reboot to occur at a specific time or date or after a delay by using the schedule reboot command.

· Power off and then power on the router. This method cuts off the power of the router forcibly, which might cause data loss and hardware damage. It is the least-preferred method.

To reboot a module or the router immediately:

|

Task |

Command |

Remarks |

|

Reboot a module or the router immediately. |

reboot [ slot slot-number ] |

If you do not specify the slot slot-number option, the command reboots the router (including the RFUs and interface modules). Available in user view. |

To schedule a reboot:

|

Task |

Command |

Remarks |

|

Schedule a reboot. |

· Schedule a reboot to occur at a specific time or

date: · Schedule a reboot to occur after a delay: |

Use either approach. By default, no reboot date or time or reboot delay time is specified. Available in user view. |

10 Troubleshooting

Power supply failure

Symptom

The router fails to be powered on, and the status LED on the power supply is off.

Solution

To resolve the issue:

1. Verify that the power cord is connected correctly and reliably.

2. Verify that the power source is as required by the power supply.

3. Verify that the router operates at acceptable temperature ranges and the power supply has good ventilation.

4. If the issue persists, contact H3C Support.

To replace a power supply, see "Replacing a power supply."

Fan tray failure

Symptom

The system reports a fan tray failure:

%May 22 10:13:17:666 2023 H3C DEV/2/FAN_FAILED: Fan 1 failed.

The RUN status LED on the fan tray is steady yellow.

Solution

To resolve the issue:

1. Verify that the air inlet and outlet vents of the chassis are not blocked. Clear the obstructions if any.

2. Replace the fan tray.

3. If the issue persists, contact H3C Support.

Configuration terminal display issue

No display

Symptom

The configuration terminal does not have display when the router is powered on.

Solution

To resolve the issue:

1. Verify that the power system is operating correctly.

2. Verify that the console cable is correctly connected.

3. Verify that the console cable does not have any issues and the terminal settings are correct.

4. If the issue persists, contact H3C Support.

Garbled display

Symptom

The display on the configuration terminal is garbled.

Solution

To resolve the issue:

1. Verify that the terminal parameters are configured as follows:

¡ Baud rate—9600.

¡ Data bits—8.

¡ Stop bits—1.

¡ Parity—None.

¡ Flow control—None.

2. If the issue persists, contact H3C Support.

Interface module, cable, and connection failure

Symptom

After an interface module is installed and the router is powered on, the LEDs on the interface module panel indicate that the interface module is operating incorrectly.

Solution

To resolve the issue:

1. Verify that the interface module is installed correctly.

2. Verify that the router supports the interface module.

3. Verify that the interface module is installed in the compatible slot.

4. Verify that a correct cable is used.

5. Verify that the cable is correctly connected.

6. If the issue persists, contact H3C Support.

System failure during operation

Symptom

A system failure occurs during router operation.

Solution

Press the reset button (RESET) to reboot the router.

Guidelines for using the reset button

|

IMPORTANT: · The reset button can only reboot the router and cannot restore the router to the factory default. · For the reset button to take effect, you must press it for a minimum of 0.5s. |

· When only one RFU is present on the router, pressing the reset button reboots the router.

· When two RFUs run on the router, pressing the reset button on the active RFU will trigger an active/standby RFU switchover without interrupting the system operation.

· When two RFUs run on the router, pressing the reset button on the standby RFU will reset the standby RFU without affecting the system operation.