Country / Region

H3C SDN Network Upgrade Gives Steel Industry a Fresh Start

The steel industry has always been an important industry sector in China, and forms a key component of both the Industry 4.0 and "intelligent manufacturing in China" strategies. But increasing the efficiency and intelligence of industries such as steel – with its traditional manufacturing processes – makes integration of advanced IT technologies – in areas such as production process optimization, decision support, office automation, and supply chain integration – particularly important.

A new, large-scale specialist industrial, H3C’s customer is the most famous Iron and Steel Group in China, with a leading strategic position, and a high-quality, high-performance, environmentally-friendly, process assurance capability that is already advanced by international standards.

Multi-network Concurrence: Security, Efficiency and Cost are Key

For any network upgrade process, a large-scale, highly-developed starting-point network system massively complicates planning and deployment. In any company’s data center, network includes many subsystems such as office intranets, energy networks, and safety networks. Often multiple networks co-exist in the data center, connected to office system via firewalled external networks. These scenarios require solution-wide integrated planning of reliability, performance, network security, and load balancing to ensure safe and stable simultaneous operation of multiple services.

Aiming to "build a dream factory for smart manufacturing", the Steel Group planned to use advanced telecommunication facilities and computer systems to develop it key technological platform for smart production and operation. In the end, after many proof-of-concept demonstrations, H3C's SDN-based ADDC solution was chosen, to become the cornerstone of the Group’s data center network.

Powerful Hardware Breaks Performance Bottlenecks

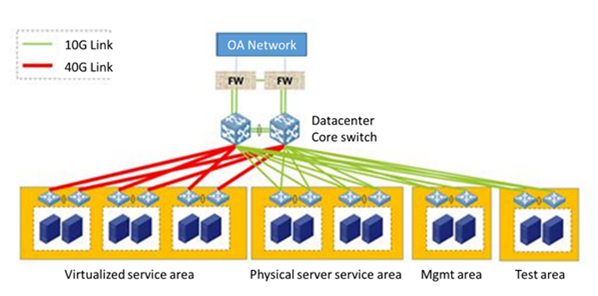

The new system arranges extranet, intranet, energy, and safety networks in a star topology, with dual-core dual-aggregation nodes deployed in each area for improved network reliability and operational stability. A data highway interconnecting the data center core switch and the virtualized service area access switch is established using a 40 Gbit/s link.

Three of H3C's high-end core switches (S12508X-AF, S10508, S7506E, and S7504E-XS), form the pillars of the company's network system, supported by hundreds of access switches, and 802.11ac wireless APs. Large-scale switches and high-performance APs ensure high-performance, high-efficiency operation of the entire network, eliminating any bottlenecks the underlying hardware might cause.

At the junction between the data center and Intranet, safety, energy, and operations networks, New N3C security gateways ensure security providing firewall, IPS, and load balancing services. Inside the data center, security protection equipment for IT O&M audit, and vulnerability scanning service, together with bastion hosts, have been deployed.

The Application-Driven Data Centre (ADDC) leverages hard and software fully

Virtualization – involving layers of hardware virtualized as software running on solid hardware platforms - is the only way to reduce system costs and improve resource utilization. But simple virtualization technology can entail problems with security, performance, and reliability, and as such systems expand, these challenges can only increase.

H3C plans system architecture, equipment selection, system deployment, and the post-upgrade phase from multiple perspectives, to build safe, flexible and efficient network systems based on the latest Application-Driven Data Centre (ADDC) interconnection concepts.

Data center architecture

In the new data center architecture, each network’s service area acts as an independent security area – or virtual private data center – such that hosts, storage, firewalls, networks, and databases together form a Virtual Private Cloud (VPC). Service systems can thus mutually, independently, and flexibly access one another.

Finally, the ADDC solution allows four virtual data centers to be constructed on one physical network while keeping the extra-, intra-, safety, and monitoring networks logically isolated. In addition, H3C also built a large-scale L2 VxLAN-technology virtualized network, implementing virtualized multi-tenant security via use of firewalls.

H3C’s ADDC Director allows monitoring of the operational status of the entire data center, traffic monitoring, automatic deployment, automatic discovery, and unified management of both the underlay and overlay networks. Acting as ‘steward’ of the ADDC solution, ADDC Director is its operators’ most important tool, also allowing management of applications/services and their supporting infrastructure from end-to-end, and planning, deployment, monitoring, and optimization over entire application life cycles.

The successful commercialization of the ADDC solution provides a complete set of effective solutions for the construction, maintenance, and upgrade of future cloud data centers, which H3C plans to develop into customized network solutions to help further upgrade and transform the Steel Group’s data center network over the coming years.

Iron and steel is a stereotypical traditional heavy industry. But with H3C’s guidance, the Group has broken its industry’s mould, and made great innovations in its data center construction. The promise of SDN technology and ADDC solutions here is not only satisfaction of present and future business needs and operational requirements, but also the provision of a model of transformation for the steel industry in Shandong – and perhaps China – as a whole, setting the scene for the adoption of next-generation network architectures across all of China's heavy industries.