- Table of Contents

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 01-Text | 5.99 MB |

Contents

Chassis views and technical specifications

Examining the installation site

Attaching the slide rails to the rack

Installing mounting brackets and cable management brackets

Installing the switch in the rack

Accessing the switch for the first time

This installation quick start provides basic instructions for installing an S7500E switch. For more information about the installation procedure, see H3C S7500E Switch Series Installation Guide.

The installation procedure is similar for all S7500E switch models. This installation quick start uses the S7503E switch as an example.

|

|

NOTE: The figures in this installation quick start are for illustration only. |

Chassis views and technical specifications

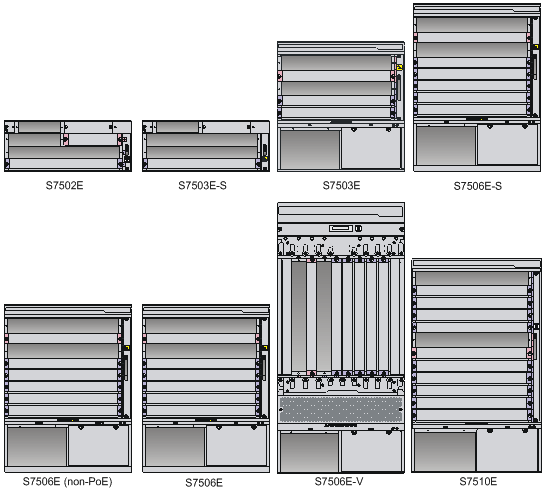

Chassis views

Figure 1 Chassis

Figure 2 S7503E switch front panel

|

(1) MPU slots |

(2) LPU slots |

|

(3) Power module slots |

(4) Fan tray slot |

Technical specifications

|

Model |

Height |

Width |

Depth |

|

S7502E |

175 mm (6.89 in) (4 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7503-S |

175 mm (6.89 in) (4 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7503E |

441 mm (17.36 in) (10 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7506E-S |

575 mm (22.64 in) (13 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7506E (non-PoE) |

575 mm (22.64 in) (13 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7506E |

575 mm (22.64 in) (13 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7506E-V |

930 mm (36.61 in) (21 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

|

S7510E |

708 mm (27.87 in) (16 RU) |

436 mm (17.17 in) |

420 mm (16.54 in) |

Table 2 Power module specifications

|

Model |

Rated voltage range |

Maximum output power |

Support for PoE |

Maximum PoE output power |

|

PSR320-A |

100 VAC to 240 VAC @ 50/60Hz |

300 W |

No |

N/A |

|

PSR320-D |

–48 VDC to –60 VDC |

300 W |

No |

N/A |

|

PSR650-A |

100 VAC to 240 VAC @ 50/60Hz |

650 W |

No |

N/A |

|

PSR650-D |

–48 VDC to –60 VDC |

650 W |

No |

N/A |

|

PSR650C-12A |

100 VAC to 240 VAC @ 50/60Hz |

650 W |

No |

N/A |

|

PSR650C-12D |

–48 VDC to –60 VDC |

650 W |

No |

N/A |

|

PSR1400-A |

100 VAC to 240 VAC @ 50/60Hz |

1150 W (110 VAC) |

No |

N/A |

|

1400 W (220 VAC) |

No |

N/A |

||

|

PSR1400-D |

–48 VDC to –60 VDC |

1400 W |

Yes |

6720 W |

|

PSR1400-12D1 |

–48 VDC to –60 VDC |

1400 W |

No |

N/A |

|

PSR2800-ACV |

100 VAC to 240 VAC @ 50/60Hz |

1150 W (110 VAC) |

Yes |

1150 W |

|

1400 W (220 VAC) |

Yes |

1400 W |

||

|

PSR6000-ACV |

100 VAC to 240 VAC @ 50/60Hz |

1150 W (110 VAC) |

Yes |

· One PoE input: 1200 W · Two PoE inputs: 2400 W · Three PoE inputs: 3600 W |

|

1400 W (220 VAC) |

Yes |

· One PoE input: 1800 W · Two PoE inputs: 3600 W · Three PoE inputs: 5300 W |

Table 3 Power module and chassis compatibility matrix

|

Power module |

Chassis |

|||||||

|

S7502E |

S7503E-S |

S7503E |

S7506E |

S7506E-S |

S7506E (non-PoE) |

S7506E-V |

S7510E |

|

|

PSR320-A |

l |

l |

— |

— |

— |

— |

— |

— |

|

PSR320-D |

l |

l |

— |

— |

— |

— |

— |

— |

|

PSR650-A |

l |

l |

? |

? |

? |

? |

? |

— |

|

PSR650-D |

l |

l |

? |

? |

? |

? |

? |

— |

|

PSR650C-12A |

— |

— |

l |

l |

— |

l |

l |

l |

|

PSR650C-12D |

— |

— |

l |

l |

— |

l |

l |

l |

|

PSR1400-A |

— |

— |

l |

l |

l |

l |

l |

l |

|

PSR1400-D |

— |

— |

l |

l |

l |

l |

l |

l |

|

PSR1400-12D1 |

— |

— |

l |

l |

l |

l |

l |

l |

|

PSR2800-ACV |

— |

— |

l |

l |

l |

— |

l |

l |

|

PSR6000-ACV |

— |

— |

l |

l |

l |

— |

l |

l |

|

|

NOTE: · "l" indicates that the power module can be directly installed on the chassis. · "?" indicates that you must first install a power module adapter on the chassis and then install the power module on the power module adapter. · "—" indicates that the power module cannot be installed on the chassis. |

Safety recommendations

To avoid equipment damage or bodily injury caused by improper use, read the following safety recommendations before installation. Note that the recommendations do not cover every possible hazardous condition.

· To prevent ESD damage, always wear an ESD wrist strap and make sure it is reliably grounded before you touch the switch, cards, or PCB.

· Do not install the switch, FRUs, or cables when the switch is powered on.

· To avoid equipment damage or bodily injury, make sure the switch is reliably grounded before powering on the switch.

· To ensure good ventilation, install a blank filler panel in an unused slot.

Figure 3 Attaching an ESD wrist strap

Examining the installation site

The switch can only be used indoors. To make sure the switch operates correctly and prolong its service lifetime, the installation site must meet the requirements for load-bearing, temperature, humidity, cleanness, EMI, grounding power module, ventilation, and space. For more information, see H3C S7500E Switch Series Installation Guide.

Installing the switch

Attaching the slide rails to the rack

1. Read the signs on the slide rails to identify the left and right slide rails and their front ends, as shown in Table 4.

Table 4 Description for signs on the slide rails

|

Sign |

Meaning |

Remarks |

|

F/L |

Front end of the left slide rail |

Mount this end to the front left rack post. |

|

F/R |

Front end of the right slide rail |

Mount this end to the front right rack post. |

2. Mark the installation position on the rack for the slide rails:

a. Make sure the top flange of a slide rail aligns with the middle of the narrower metal area between holes in a rack post, as shown in Figure 4.

b. Each rack post requires six screws to attach the slide rail. Mark only the uppermost and lowermost holes.

c. Mark the square holes at the same height on the other three rack posts.

Figure 4 Determining the cage nut installation holes by using a slide rail

|

(1) Middle of the narrower metal area between holes |

3. Install six cage nuts in the square holes in each rack post, as shown in Figure 5.

Figure 5 Installing a cage nut

4. Align the installation holes on the front end of a slide rail with the cage nuts on a front rack post, and use six screws to attach the slide rail to the front rack post. Figure 6 uses the right slide rail as an example.

Figure 6 Attaching the right slide rail to the front right rack post

5. Keep the slide rail horizontal and adjust its length until the installation holes on the rear end of the slide rail touch the cage nuts on the rear rack post. Then use screws to attach the slide rail to the rear rack post.

6. Repeat steps 4 and 5 to install the other slide rail. Make sure the two slide rails are at the same height so that the switch can be placed on them horizontally.

Installing cage nuts

1. Determine and mark the cage nut installation holes on the front rack posts ,as shown in Figure 7.

Figure 7 Cage nut installation holes

Figure 8 Marking the cage nut installation holes

2. Install the cage nuts.

Installing mounting brackets and cable management brackets

Installing the cable management brackets on the S7506E-V

The S7506E-V has two cable management brackets: the one with a tray is installed at the lower part of the switch, and the one without a tray is installed at the upper part of the switch. They are installed in the same way.

To install a cable management bracket:

1. Unpack the cable management brackets.

2. Attach the cable management bracket to the chassis, and align the screws with the screw holes in the chassis, as shown in Figure 9.

3. Fasten the screws.

Figure 9 Installing cable management brackets on an S7506E-V

Installing the cable management brackets on other models

For the models except the S7506E-V, install the cable management bracket on the left mounting bracket, as shown in Figure 10. The switch is supplied with two mounting brackets, and the one with the cable management bracket screw holes is the left mounting bracket.

Figure 10 Attaching the cable management bracket to the left mounting bracket

Installing the mounting brackets

Before installing the switch in the rack, install the mounting brackets to the chassis, as shown in Figure 11.

· S7506E-V—Facing the front of the switch, mount the left and right mounting brackets to the two sides of the switch.

· Other models—Facing the front of the switch, mount the mounting bracket with a cable management bracket to the left of the switch, and mount the mounting bracket without a cable management bracket to the right of the switch (where the fan tray is located).

Figure 11 Installing the mounting brackets

Installing the switch in the rack

Follow these guidelines when you install the switch in the rack:

· To avoid equipment damage or bodily injury, use a minimum of two people to lift the switch. H3C recommends that you use a mechanical lift to move the switch.

· Do not hold the filler panels, filler panel handles, or the air vents of chassis to carry the chassis. Any attempt to carry the switch with these parts might cause equipment damage or even bodily injury.

· After placing the switch on the slide rails, do not leave go of your hands immediately because this might tip the switch. Tipping the switch can cause switch damage and even bodily injury.

Figure 12 Installing the switch in the rack

Grounding the switch

|

|

CAUTION: Connect the grounding cable to the grounding system in the equipment room. Do not connect it to a fire main or lightning rod. |

Use the provided grounding cable (yellow-green grounding cable).

Figure 13 Grounding the switch

Installing FRUs

Installing a card

|

|

IMPORTANT: · Before installing a card in the chassis, make sure the connectors on the card are not broken or blocked. · To ensure good ventilation, install a blank filler panel in an empty slot. |

Figure 14 Installing a card

Installing a power module

|

|

CAUTION: · Provide a circuit breaker for each power module and make sure the circuit breaker is off before installation. · Do not install power modules of different models on the same switch. · For dual-grid input, the input voltage and frequency for the two grids must be the same. · To avoid power module damage or bodily injury, support the bottom of a power module instead of holding its handle to move the power module. · To ensure good ventilation, install a blank filler panel over an empty slot. |

After you push the power module into the slot, press the power module handle inward until it is secured in place, and then fasten the captive screws on the power module.

Figure 15 Installing a power module

Connecting power cords

Connecting the PSR320-A/PSR650-A power cord

Figure 16 Connecting the PSR320-A/PSR650-A power cord

Connecting the PSR650C-12A power cord

Figure 17 Connecting the PSR650C-12A power cord

Connecting the PSR1400-A power cord

Figure 18 Connecting the PSR1400-A power cord

Connecting the PSR2800-ACV power cord

The PSR2800-ACV is a built-in power module with AC input and DC output. It provides one system power socket and one PoE power socket. The methods for connecting the system power cord and PoE power cord are similar to connecting the PSR1400-A power cord. For more information, see "Connecting the PSR1400-A power cord."

Connecting the PSR6000-ACV power cord

The PSR6000-ACV is a built-in power module with AC input and DC output. It provides one system power socket and three PoE power sockets. Connecting the system power cord is the same as connecting the PoE power cord. The following illustrates how to connect the system power cord.

To attach the power cord retainer suite:

1. Fasten the retainer suite to the plug of the power cord, making sure you can align the screw holes in the retainer suite with the screw holes in the power module.

If you cannot align the screw holes in the retainer suite with the screw holes in the power module, pull the cable retainer suite outwards, rotate it by 180 degrees, and push it in until it is secured in place.

2. Use a Phillips screwdriver to fasten the two parts of the retainer suite together.

Figure 19 Attaching the power cord retainer suite

|

(1) Screw holes for connecting the retainer suite to the power module |

(2) Power cord plug |

|

(3) Screw holes for connecting the two parts of the retainer suite |

|

3. Insert the power cord into the power socket on the power module, and fasten the power cord retainer suite to the power module.

Figure 20 Connecting the AC power cord to the PSR6000-ACV

Connecting the PSR320-D/PSR650-D/PSR650C-12D power cord

Figure 21 Connecting the PSR320-D/PSR650-D/PSR650C-12D power cord

Connecting the PSR1400-D/PSR1400-12D1 power cord

Figure 22 Connecting the PSR1400-D/PSR1400-12D1 power cord

Accessing the switch for the first time

Connecting the console cable

The first time you access the switch you must use a console cable to connect a console terminal, for example, a PC, to the console port or USB console port on the switch. If both the console port and USB console port are connected to terminals, you can only access the switch through the USB console port.

To connect the console cable to the console port:

1. Connect the DB-9 connector of the console cable to the 9-core serial port on the terminal.

2. Connect the crimped RJ-45 connector of the console cable to the console port on the switch.

To connect the console cable to the USB console port:

1. Connect the USB A connector of the console cable to the USB port on the terminal.

2. Connect the mini-USB A/B connector of the console cable to the USB console port on the switch.

Figure 23 Connecting the console port to a PC

Setting terminal parameters

To configure and manage the switch through the console port, you must run a terminal emulator program, HyperTerminal or PuTTY, on your configuration terminal. You can use the emulator program to connect a network device, a Telnet site, or an SSH site. For more information about the terminal emulator programs, see the user guides for these programs.

The following are the required terminal settings:

· Bits per second—9,600.

· Data bits—8.

· Stop bits—1.

· Parity—None.

· Flow control—None.

Powering on the switch

1. Make sure the power cords are connected correctly to the power source, and the power source is supplying power correctly.

2. Turn on the circuit breakers for the power modules.

3. Power on the switch.

4. Verify that the LEDs on the switch are in the states as described Table 5. For more information about the LEDs, see H3C S7500E Switch Series Installation Guide.

Table 5 LED status when the switching is operating correctly

|

Item |

Model |

LED |

Status |

|

MPU |

LSQM3MPUA0 |

LINK/ACT |

Steady on or flashing |

|

OK |

Steady on |

||

|

FAIL |

Off |

||

|

RUN |

Flashing |

||

|

ALM |

Steady on or off |

||

|

· LSQ1MPUA0 · LSQ1CGV24PSC0 · LSQ1CGP24TSC0 · LSQ1CTGS16SC0 · LSQ1MPUB0 (Salience VI-Lite) · LSQ1SRPA0 (Salience VI-Smart) · LSQ1SRPB0 (Salience VI) · LSQ1SRPD0 (Salience VI-Plus) · LSQ1SRP1CB0 (Salience VI-Turbo) · LSQ1SRP12GB0 (Salience VI-GE) · LSQ1SRP2XB0 (Salience VI-10GE) · LSQM3MPUB0 |

LINK |

Steady on |

|

|

ACT |

Flashing or off |

||

|

OK |

Steady on |

||

|

FAIL |

Off |

||

|

RUN |

Flashing |

||

|

ACT |

Steady on or off |

||

|

· LSQM2MPUC0 · LSQM2MPUD0 · LSQM2MPUDS0 · LSQM1SRP8X2QE0 |

LINK |

Steady on |

|

|

ACT |

Flashing or off |

||

|

PWR/FAN |

Steady green |

||

|

SLOT |

Flashing green |

||

|

Power module |

· PSR320-A · PSR320-D · PSR650-A · PSR650-D |

Power module status LED |

Steady green |

|

· PSR650C-12A · PSR650C-12D · PSR1400-A · PSR1400-D · PSR1400-12D1 |

INPUT |

Steady green |

|

|

OUTPUT |

Steady green |

||

|

FAN |

Steady green |

||

|

PSR2800-ACV |

INPUT |

Steady green |

|

|

OUTPUT |

Steady green |

||

|

FAN |

Steady green |

||

|

PoE INPUT |

Steady green |

||

|

PoE OUTPUT |

Steady green |

||

|

PSR6000-ACV |

SYS IN |

Steady green |

|

|

SYS OUT |

Steady green |

||

|

SYS FAN |

Steady green |

||

|

PoE IN1 |

Steady green |

||

|

PoE IN2 |

Steady green |

||

|

PoE IN3 |

Steady green |

||

|

PoE OUT |

Steady green |

||

|

PoE FAN |

Steady green |

Obtaining documentation

Take the following steps to get related documents from the H3C website at www.h3c.com.hk.