- Table of Contents

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 01-Installation Guide | 3.68 MB |

Examining the installation site

Installation methods and accessories

Installation methods and rack requirements

Rack-mounting procedures at a glance

Mounting the switch in a 19-inch rack

Rack-mounting the switch by using front and rear mounting brackets

Rack-mounting by using front mounting brackets and long or super-short slide rails

Grounding the switch by using a grounding strip

Installing/removing power supplies

Connecting the power cord for a PSR450-12A/PSR450-12A1 power supply

Connecting the power cord for a PSR450-12AHD power supply

Connecting the DC power cord for a PSR450-12D power supply

3 Accessing the switch for the first time

Connecting the switch to a configuration terminal

Connecting a DB9-to-RJ45 console cable

Connecting a USB-to-RJ45 console cable

4 Maintenance and troubleshooting

Configuration terminal display issues

1 Preparing for installation

The S6880 switch series includes the following models:

|

Product code |

Product model |

|

LS-6880-48Y8C |

S6880-48Y8C |

|

LS-6880-48X8C |

S6880-48X8C |

Safety recommendations

To avoid any equipment damage or bodily injury, read the following safety recommendations before installation. Note that the recommendations do not cover every possible hazardous condition.

· Before cleaning the switch, remove all power cords from the switch. Do not clean the switch with wet cloth or liquid.

· Do not place the switch near water or in a damp environment. Prevent water or moisture from entering the switch chassis.

· Do not place the switch on an unstable case or desk. The switch might be severely damaged in case of a fall.

· Ensure good ventilation of the equipment room and keep the air inlet and outlet vents of the switch free of obstruction.

· Make sure the operating voltage is in the required range.

· To avoid electrical shocks, do not open the chassis while the switch is operating or when the switch is just powered off.

· To avoid ESD damage, always wear an ESD wrist strap when replacing a power supply or fan tray.

Examining the installation site

You must install the switch indoors and make sure the following requirements are met:

· Adequate clearance is reserved at the air inlet and outlet vents for ventilation.

· The rack has a good ventilation system.

· Identify the hot aisle and cold aisle at the installation site, and make sure ambient air flows into the switch from the cold aisle and exhausts to the hot aisle.

· Identify the airflow designs of neighboring devices, and prevent hot air flowing out of the neighboring devices from entering the top device.

· The rack is sturdy enough to support the switch and its accessories.

· The rack is reliably grounded.

To ensure correct operation and long service life of your switch, install it in an environment that meets the requirements described in the following subsections.

Temperature/humidity

Maintain temperature and humidity in the equipment room at acceptable ranges.

· Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical property change of materials, and metal corrosion.

· Lasting low relative humidity can cause washer contraction and ESD and cause issues including loose mounting screws and circuit failure.

· High temperature can accelerate the aging of insulation materials and significantly lower the reliability and lifespan of the switch.

For the temperature and humidity requirements, see hardware information and specifications for the switch.

Cleanliness

Dust buildup on the chassis might cause electrostatic adsorption and dust corrosion, resulting in poor contact of metal connectors and contact points. This might shorten the device's lifetime and even cause device failure in the worst case. Table1-1 describes the dust concentration limits in the equipment room.

Table1-1 Dust concentration limits in the equipment room for the switch

|

Dust |

Particle diameter |

Maximum allowable concentration |

|

Dust particles |

≥ 0.5 µm |

3.5 × 106 particles/m3 |

|

Dust particles |

≥ 5 µm |

3 × 104 particles/m3 |

|

Dust (suspension) |

≤ 75 µm |

0.2 mg/m3 |

|

Dust (sedimentation) |

75 µm to 150 µm |

1.5 mg/(m2h) |

To maintain cleanliness in the equipment room, follow these guidelines:

· Keep the equipment room away from pollution sources. Do not smoke, eat, or drink in the equipment room.

· Use double-glazed windows and seal doors and windows with dust-proof rubber strips. Use screen doors and window screens for doors and windows open to the outside and make sure the external windows are air tight.

· Use dustproof materials for floors, walls, and ceilings and use wallpaper or matt paint that does not produce powders.

· Clean the equipment room regularly and clean the air filters of the rack each month.

· Wear ESD clothing and shoe covers before entering the equipment room. Keep the ESD clothing and shoe covers clean and change them frequently.

Corrosive gas limit

Corrosive gases can accelerate corrosion and aging of metal components. Make sure the corrosive gases in the equipment room do not exceed the concentration limits as shown in Table1-2.

Table1-2 Corrosive gas concentration limits in the equipment room

|

Gas |

Average concentration (mg/m3) |

Maximum allowable concentration (mg/m3) |

|

SO2 |

0.3 |

1.0 |

|

H2S |

0.1 |

0.5 |

|

Cl2 |

0.1 |

0.3 |

|

HCI |

0.1 |

0.5 |

|

HF |

0.01 |

0.03 |

|

NH3 |

1.0 |

3.0 |

|

O3 |

0.05 |

0.1 |

|

NOX |

0.5 |

1.0 |

|

CAUTION: As a best practice, control the corrosive gas in the equipment room at the average concentration values. Make sure the corrosive gas will not be in their maximum allowable concentration values for over 30 minutes per day. |

To control corrosive gases, use the following guidelines:

· As a best practice, do not build the equipment room in a place with a high concentration of corrosive gases.

· Make sure the equipment room is not connected to sewer, vertical shaft, or septic tank pipelines and keep it far away from these pipelines. The air inlets in the equipment room must be away from such pollution sources.

· Use environmentally friendly materials to decorate the equipment room. Avoid using organic materials that contain harmful gases, such as sulfur or chlorine-containing insulation cottons, rubber mats, sound-proof cottons, and avoid using plasterboards with high sulfur concentration.

· Place fuel (diesel or gasoline) engines separately. Do not place them in the same equipment room with the device. Make sure the air exhausted from the engines will not flow into the equipment room or towards the air inlets of the air conditioners.

· Place batteries separately. Do not place them in the same room with the device.

· Employ a professional company to monitor and control corrosive gases in the equipment room regularly.

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application system, adversely affect the switch in the following ways:

· A conduction pattern of capacitance coupling.

· Inductance coupling.

· Electromagnetic wave radiation.

· Common impedance (including the grounding system) coupling.

To prevent EMI, use the following guidelines:

· If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to filter interference from the power grid.

· Keep the switch far away from radio transmitting stations, radar stations, and high-frequency devices.

· Use electromagnetic shielding, for example, shielded interface cables, when necessary.

· To prevent signal ports from getting damaged by overvoltage or overcurrent caused by lightning strikes, route interface cables only indoors.

Laser safety

|

WARNING! · The switch is a Class 1 laser device. · Disconnected optical fibers or transceiver modules might emit invisible laser light. Do not stare into beams or view directly with optical instruments when the switch is operating. |

Installation tools

No installation tools are provided with the switch. Prepare the following tools yourself:

· Flat-head screwdriver.

· Phillips screwdriver.

· ESD wrist strap.

· Marker.

· Heat gun.

· Wire stripper.

· Diagonal pliers.

Installation accessories

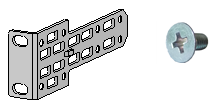

Before installation, make sure you have all the required installation accessories. If any accessory is damaged or missing, use the part No. provided in this table to purchase a new one.

Table1-3 Installation accessories

|

Part No. |

Description |

Quantity |

Applicable device models |

|

2150A0AN |

Front mounting kit, including a pair of front mounting brackets and eight M4 screws |

1 kit, provided |

All S6800 models |

|

2150A0BP |

Rear mounting bracket kit, including a pair of rear mounting brackets and two shoulder screws |

1 kit, provided |

All S6800 models |

|

2150A050 |

1U long slide rail and chassis rail kit |

1 kit, optional |

All S6800 models |

|

2150A0CP |

1U super-short slide rail and chassis rail kit

|

1 kit, optional |

All S6800 models |

|

2150A0GN |

1U extension slide rail and chassis rail kit |

1 kit, optional |

All S6800 models |

|

N/A |

M6 screw |

8, user supplied |

All S6800 models |

|

N/A |

Cage nut |

8, user supplied |

All S6800 models |

|

0404A0DT |

Grounding cable |

1, provided |

All S6800 models |

|

26010496 |

Grounding screw |

1, provided |

All S6800 models |

|

2114A09C |

Power supply filler panel |

1, provided |

All S6800 models |

|

· 04041104 (PSR450-12A and PSR450-12A1) · 0404A0TA (PSR450-12AHD) |

AC/HVDC power cord The appearance and parameters for power cords vary by countries and regions. The power cord in this table is a standard AC power cord in China. |

PSR450-12A/PSR450-12A1/PSR450-12AHD: 1, provided |

All S6800 models |

|

0404A00E |

DC power cord |

PSR450-12D: 1, provided |

All S6800 models |

|

0404A06R |

DB9-to-RJ45 console cable |

1, provided |

All S6800 models |

|

0404A1EE |

USB-to-RJ45 console cable |

1, optional |

All S6800 models |

2 Installing the switch

|

CAUTION: Keep the tamper-proof seal on a mounting screw on the chassis cover intact, and if you want to open the chassis, contact H3C for permission. Otherwise, H3C shall not be liable for any consequence caused thereby. |

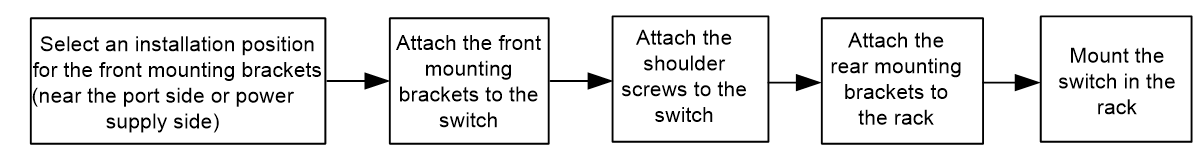

Figure2-1 Hardware installation flow

Installation methods and accessories

Installation methods and rack requirements

Table2-2 Installation methods and rack requirements

|

Installation method |

Chassis dimensions |

Requirements for the distance between the front and rear rack posts |

Rack requirements |

|

|

Install the front mounting brackets at the port side |

Front mounting brackets and rear mounting brackets with the wide flange inside the rack |

· Height—44.0 mm (1.73 in)/1 RU · Width—440 mm (17.32 in) · Depth—425 mm (16.73 in) ¡ 25 mm (0.98 in) for the power supply handle ¡ 400 mm (15.75 in) for the chassis |

372 to 536 mm (14.65 to 21.10 in) |

To close the rack door easily after cabling the switch, make sure the rack meets the following requirements: · A minimum of 130 mm (5.12 in) between the front rack posts and the front door. · A minimum of 153 mm (6.02 in) between the rear rack posts to the inner surface of the rack door. |

|

Front mounting brackets and rear mounting brackets with the wide flange outside the rack |

214 to 378 mm (8.43 to 14.88 in) |

|||

|

Install the front mounting brackets at the power supply side |

Front mounting brackets and rear mounting brackets with the wide flange inside the rack |

357 to 492 mm (14.06 to 19.37 in) |

||

|

Front mounting brackets and rear mounting brackets with the wide flange outside the rack |

200 to 335 mm (7.87 to 13.19 in) |

|||

|

Install the front mounting brackets at the port side |

Front mounting brackets and long slide rails |

634 to 793 mm (24.96 to 31.22 in) |

To close the rack door easily after cabling the switch, make sure the rack meets the following requirements: · A minimum of 130 mm (5.12 in) between the front rack posts and the front door. · A minimum of 550 mm (21.65 in) between the front rack posts and the rear door. |

|

|

Install the front mounting brackets at the power supply side |

Front mounting brackets and long slide rails |

634 to 728 mm (24.96 to 28.66 in) |

||

|

Install the front mounting brackets at the port side |

Front mounting brackets and super-short slide rails with the wide flange inside the rack |

397 to 505 mm (15.63 to 19.88 in) |

||

|

Front mounting brackets and super-short slide rails with the wide flange outside the rack |

504 to 612 mm (19.84 to 24.09 in) |

|||

|

Install the front mounting brackets at the power supply side |

Front mounting brackets and super-short slide rails with the wide flange inside the rack |

343 to 440 mm (13.50 to 17.32 in) |

||

|

Front mounting brackets and super-short slide rails with the wide flange outside the rack |

439 to 547 mm (17.28 to 21.54 in) |

|||

|

Install the front mounting brackets at the port side |

Front mounting brackets and extension slide rails |

690 to 890 mm (27.17 to 35.04 in) |

||

For information about how to mount the switch in a rack by using front mounting brackets and extension slide rails, see H3C SL-1U-SCABBARD 1U Chassis Extension Rail Kit Installation Guide.

Rack-mounting procedures at a glance

Figure2-2 Rack-mounting procedure by using front and rear mounting brackets

Figure2-3 Rack-mounting procedure by using front mounting brackets and slide rails

|

|

NOTE: If a rack shelf is available, you can put the switch on the rack shelf, slide the switch to an appropriate location, and attach the switch to the rack by using the mounting brackets. |

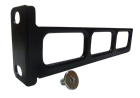

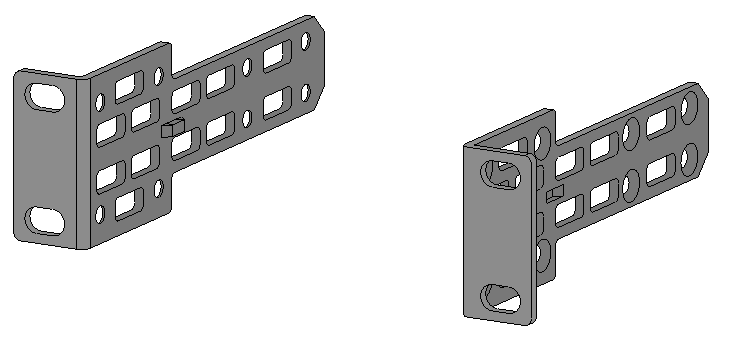

Installation accessories

Figure2-5 Rear mounting bracket and shoulder screw

|

(1) Shoulder screw |

(2) Attach the rear mounting bracket to the rack |

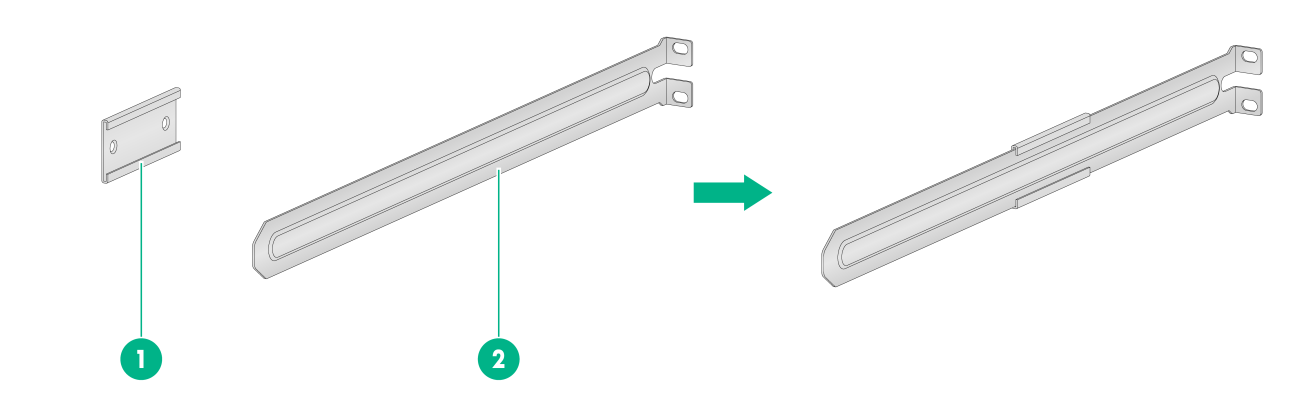

Figure2-6 1U long slide rail and chassis rail

|

(1) Chassis rail |

(2) Long slide rail |

Figure2-7 1U super-short slide rail and chassis rail

|

(1) Chassis rail |

(2) Super-short slide rail |

Mounting the switch in a 19-inch rack

Rack-mounting the switch by using front and rear mounting brackets

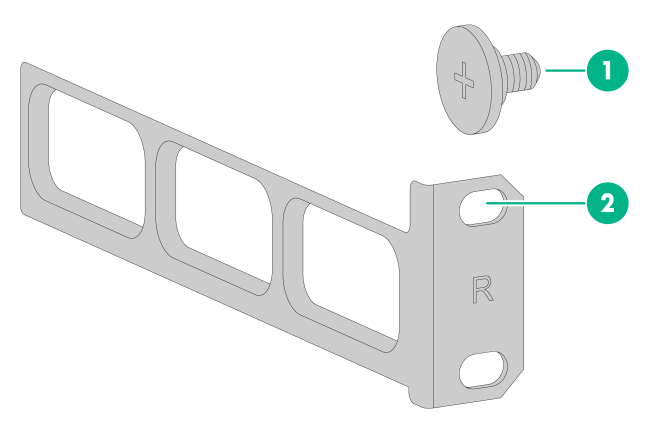

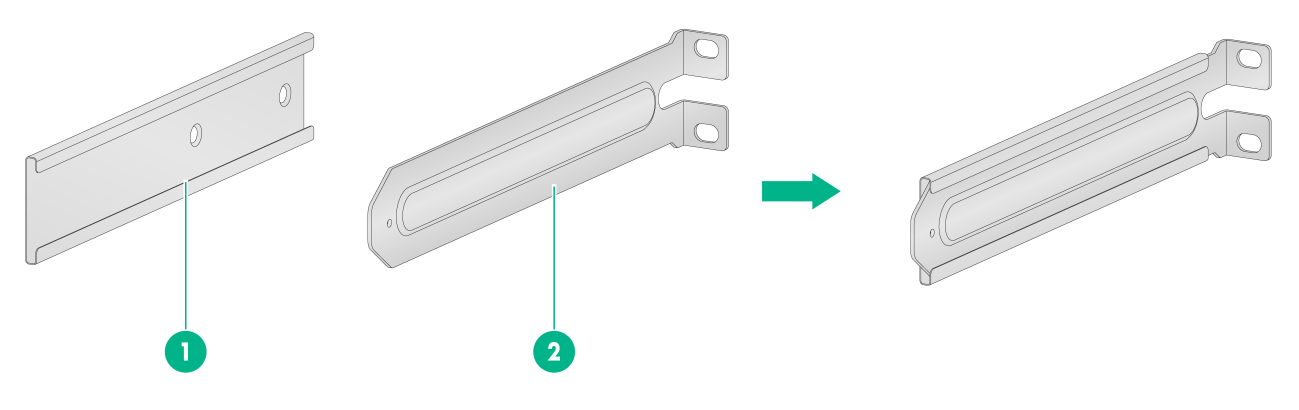

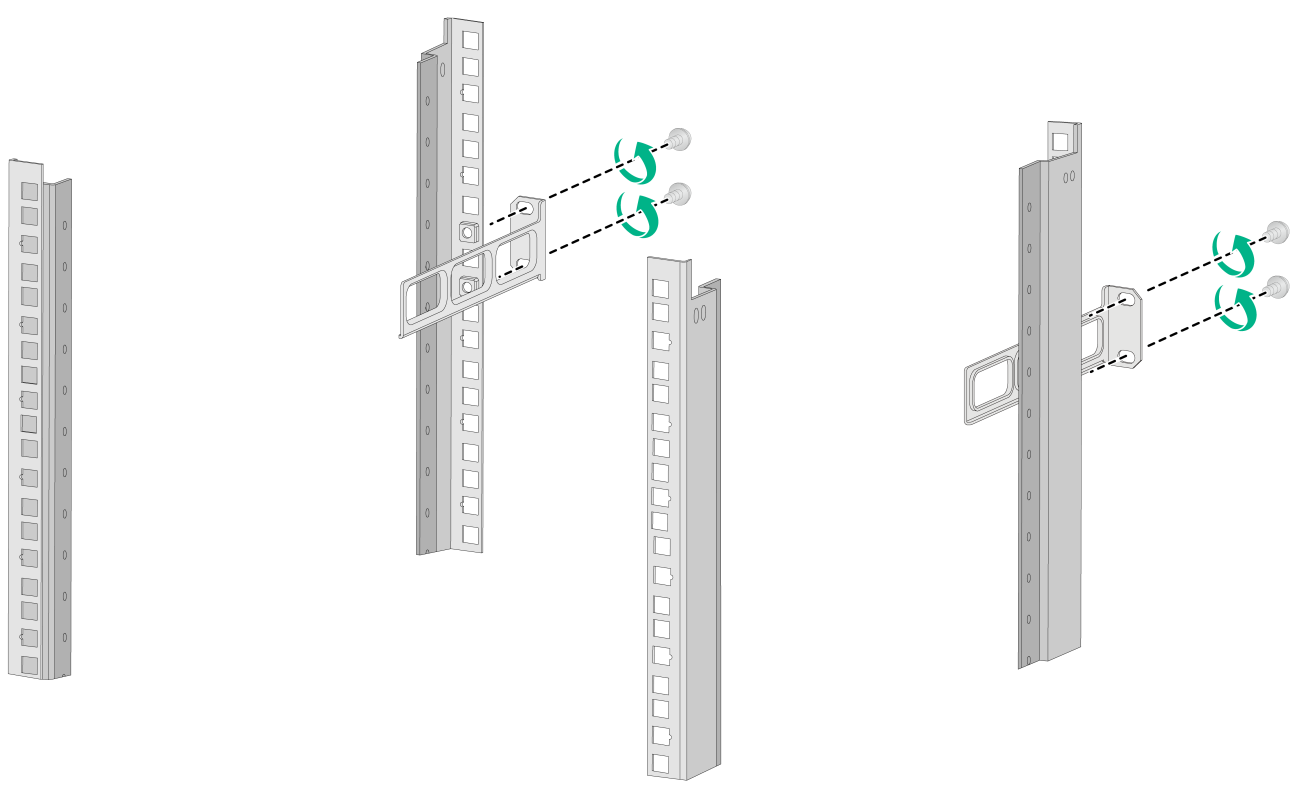

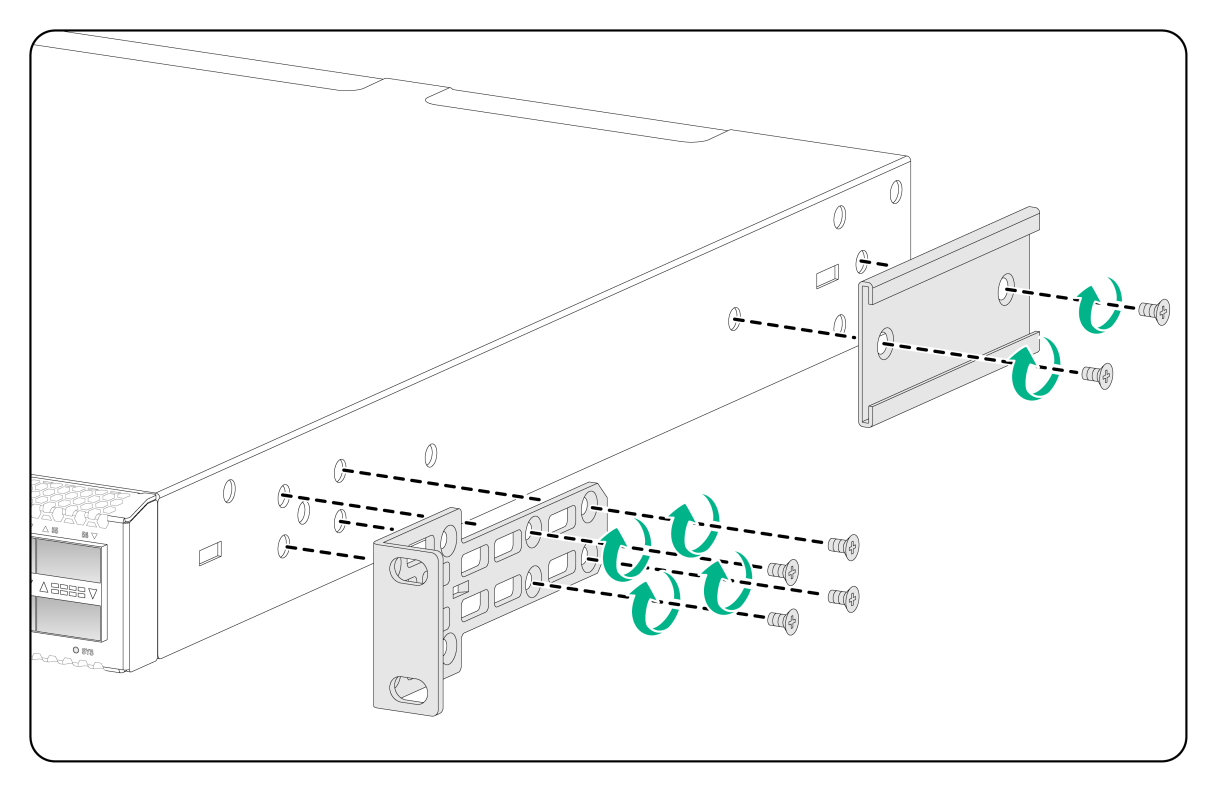

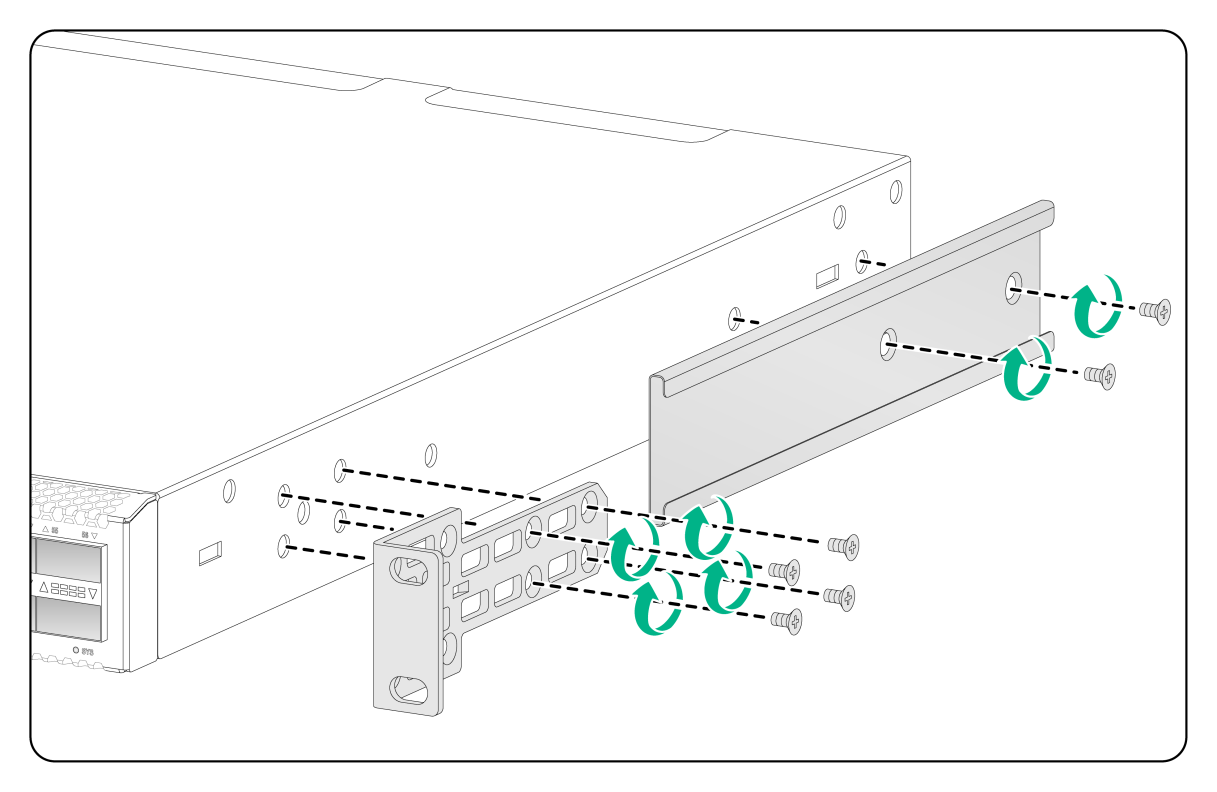

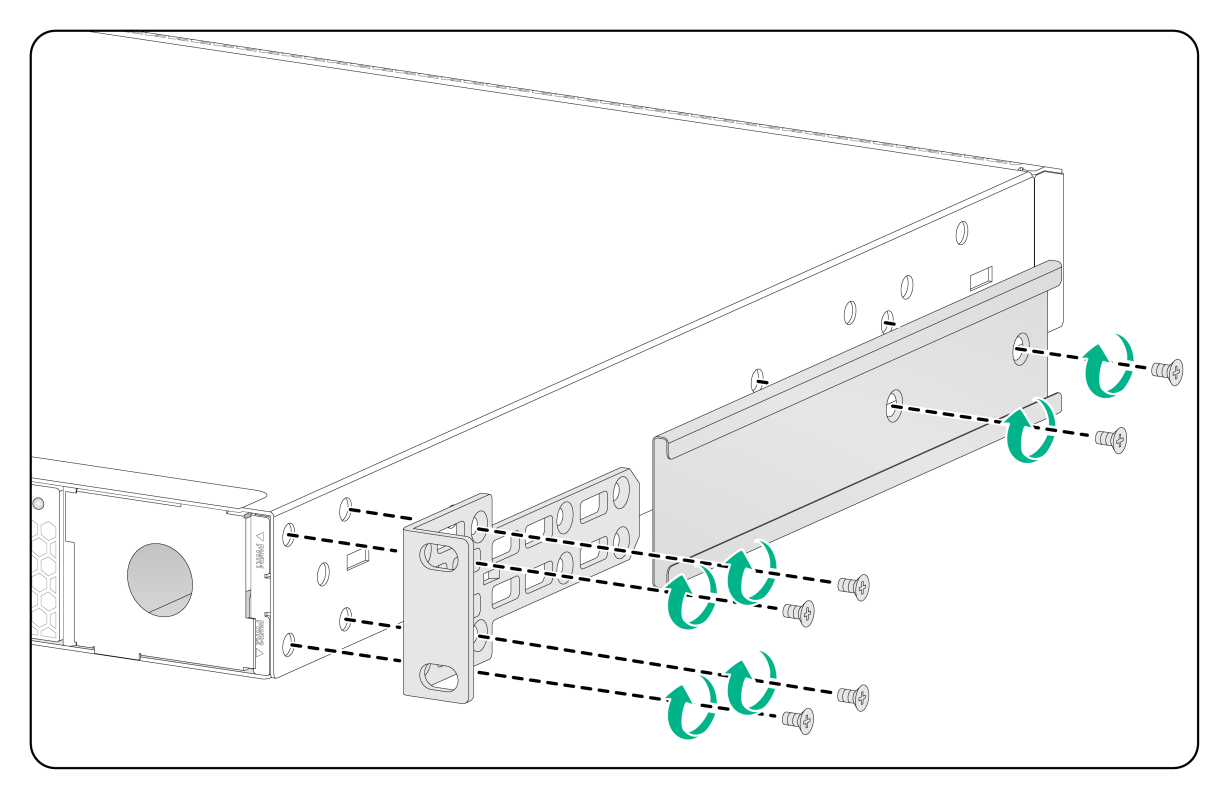

Attaching the front mounting brackets and shoulder screws to the switch

The switch provides two installation positions for front mounting brackets. One is near the port side and the other is near the power supply side. Choose the installation position for front mounting brackets according to the installation environment.

To attach the front mounting brackets and shoulder screws to the switch:

1. Align the round holes in the wide flange of one front mounting bracket with the screw holes in the chassis. See Figure2-8 and Figure2-9.

2. Use M4 screws (supplied with the switch) to attach the mounting bracket to the chassis.

As a best practice, use a torque of 12 kgf-cm (1.18 Nm) to fasten the M4 screws.

3. Repeat the preceding two steps to attach the other mounting bracket to the chassis.

4. Unpack the shoulder screw and attach it to the chassis. As a best practice, use a torque of 12 kgf-cm (1.18 Nm) to fasten the shoulder screw.

If you install the front mounting brackets at the port side, the switch provides two installation positions for the shoulder screw (red marked in Figure2-8).

If you install the front mounting brackets at the power supply side, the switch provides one installation position for the shoulder screw (red marked in Figure2-9).

The distance between the front and rear rack posts depends on the installation method of front mounting brackets. Choose one installation method according to the installation environment.

Figure2-8 Attaching the front mounting brackets and shoulder screws to the chassis (at the port-side)

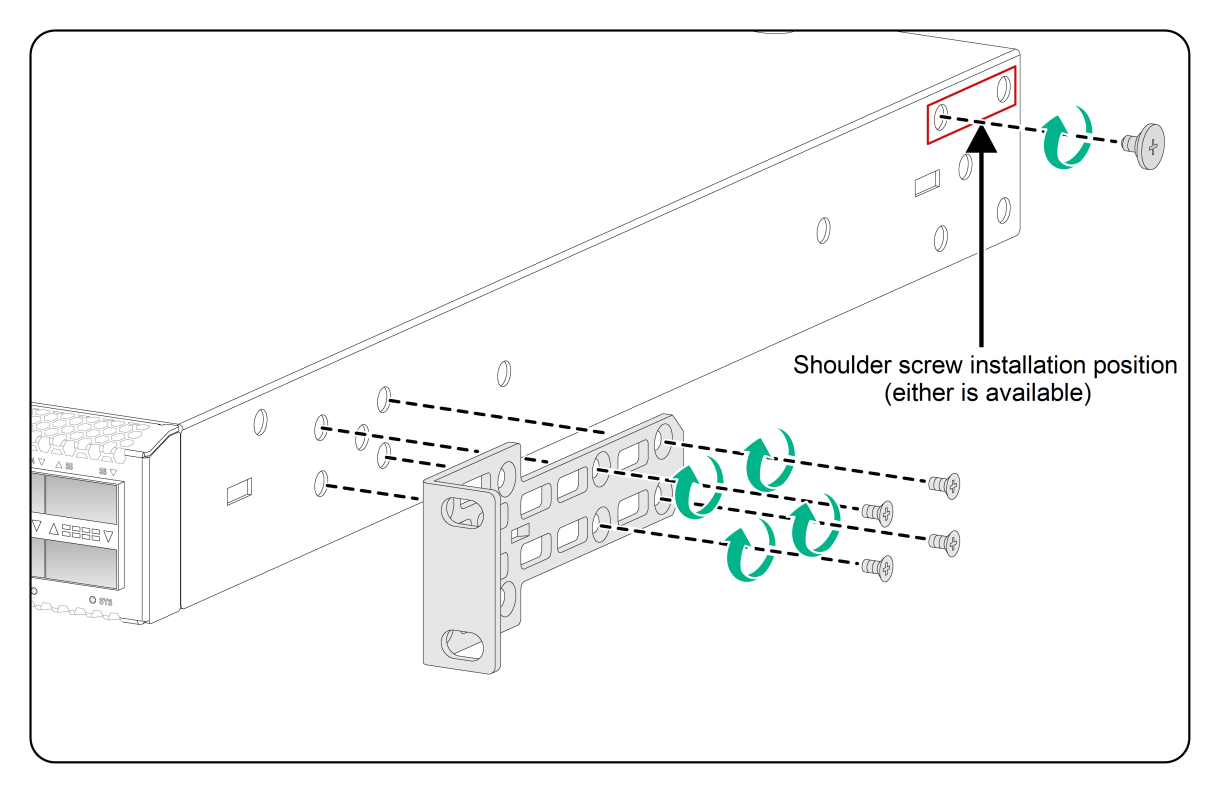

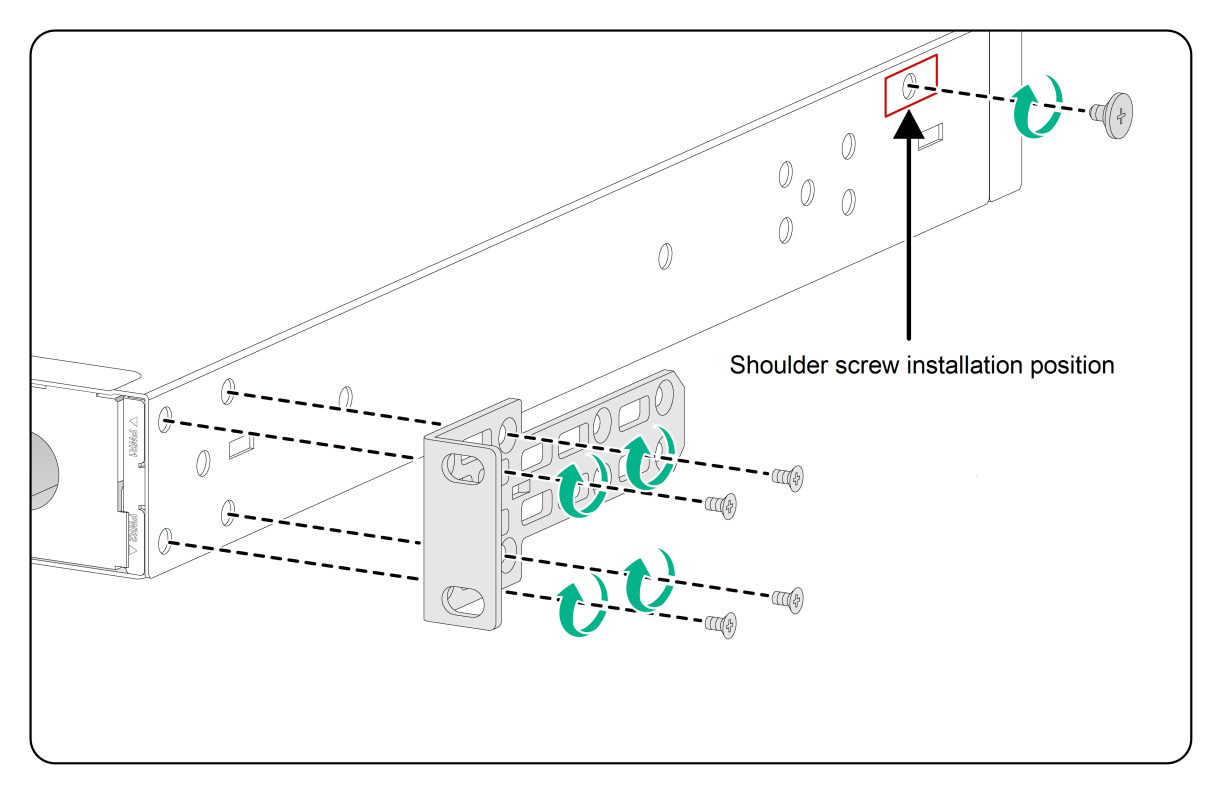

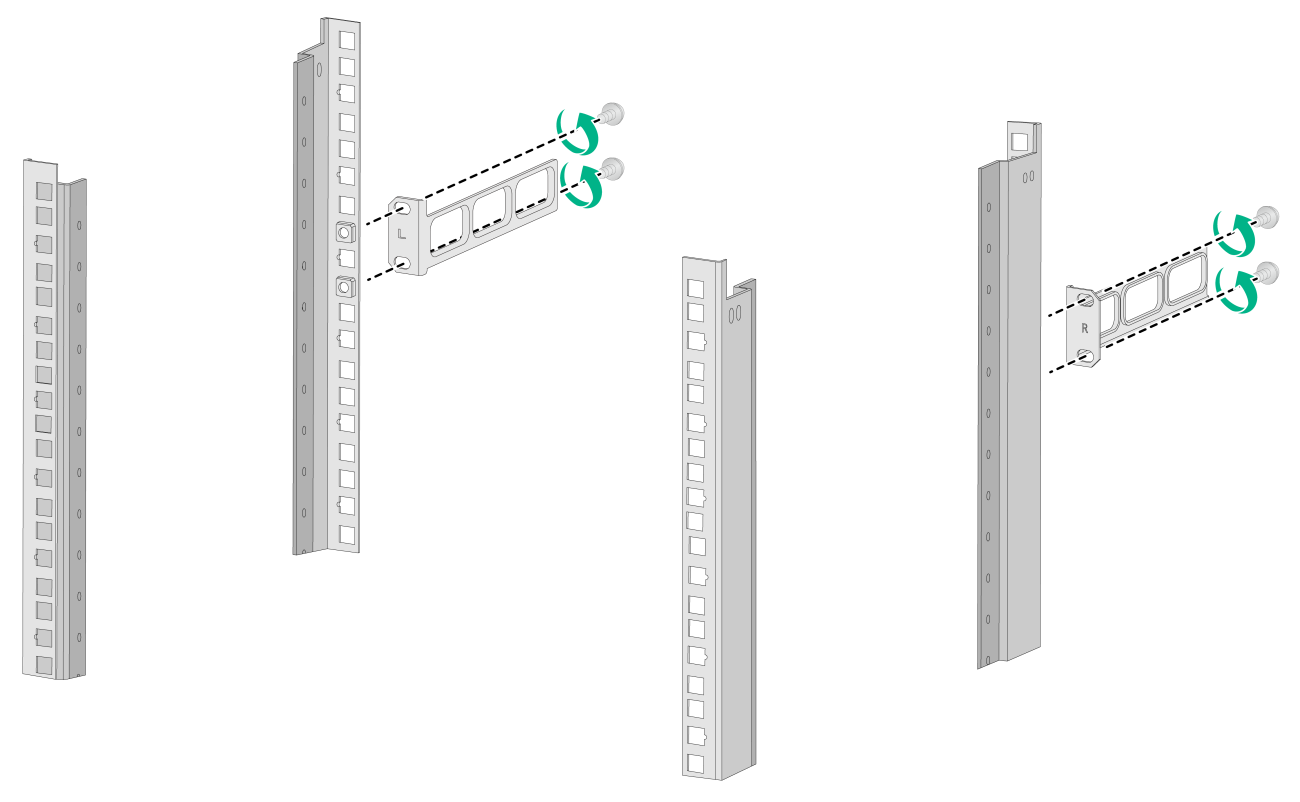

Attaching the rear mounting brackets to the rack

1. Determine the switch installation position in the rack.

2. Orient the rear mounting brackets with the wide flange inside or outside the rack as required, as shown in Figure2-10 and Figure2-11.

3. Use M6 screws and cage nuts to attach the rear mounting brackets to the rear rack posts. As a best practice, use a torque of 30 kgf-cm (2.94 Nm) to fasten the M6 screws.

Make sure the corresponding cage nuts on the left and right rear rack posts are at the same height.

Do not fully tighten the M6 screws before mounting the switch in the rack.

Figure2-10 Attaching the rear mounting brackets to the rack with the wide flange inside the rack

Figure2-11 Attaching the rear mounting brackets to the rack with the wide flange outside the rack

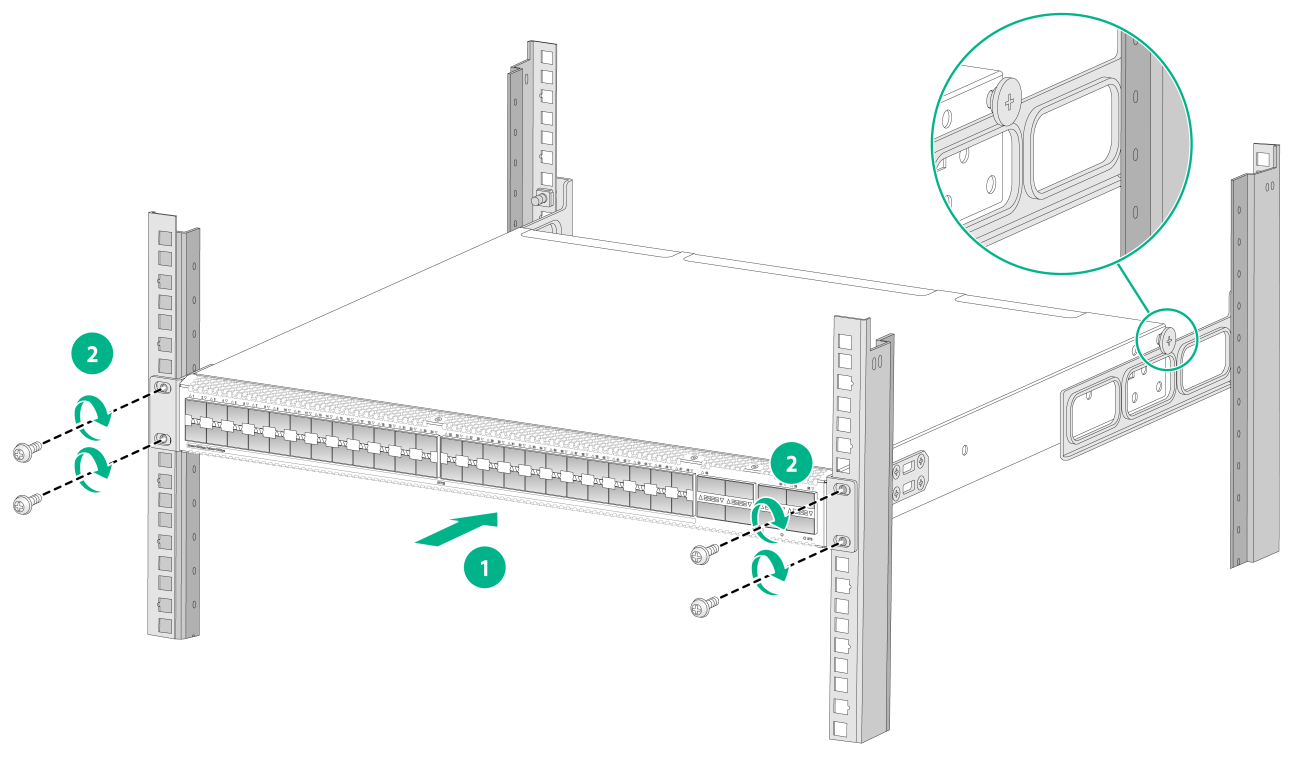

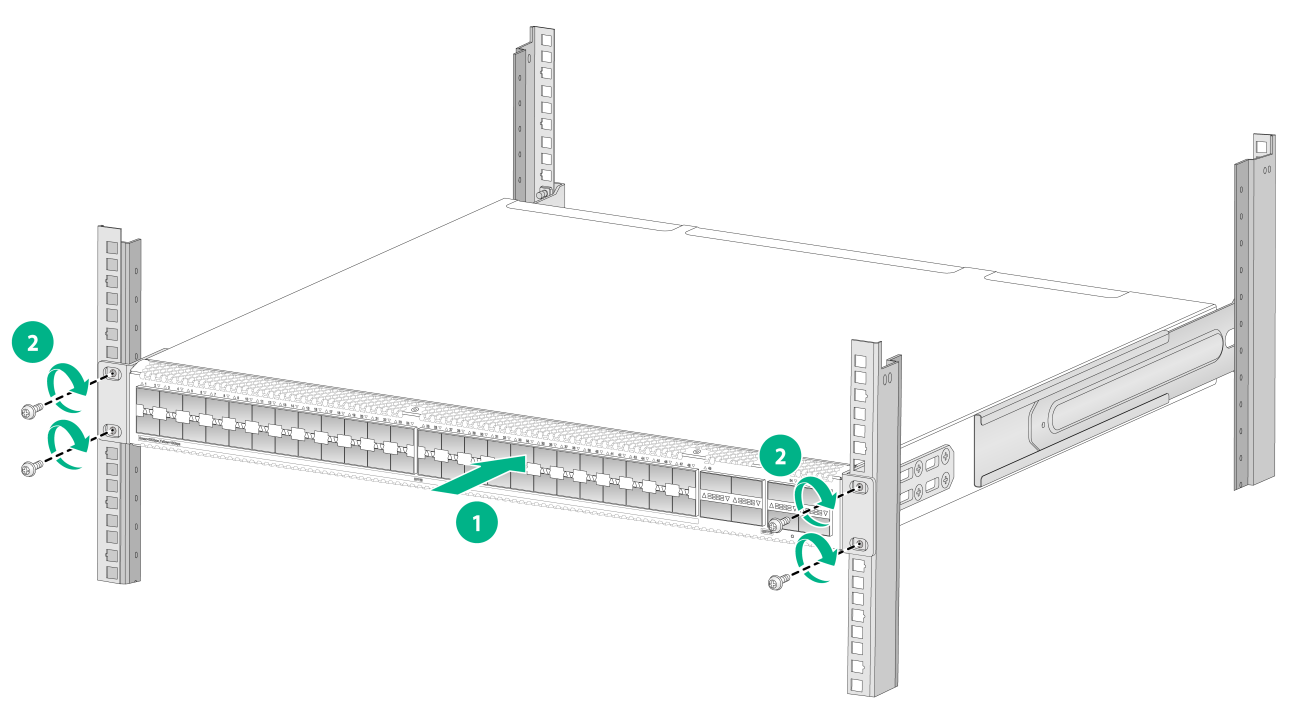

Mounting the switch in the rack

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. Verify that the front mounting brackets and shoulder screws are securely attached to the two sides of the switch. For more information, see Figure2-8 and Figure2-9.

3. Attach cage nuts to the front rack posts and make sure the corresponding cage nuts on the front and rear rack posts are at the same height.

4. One person supports the chassis bottom and pushes the chassis into the rack. Make sure the shoulder screws rest firmly on the upper edge of the rear mounting brackets. See Figure2-12 and Figure2-13.

5. The other person attaches the front mounting brackets by using M6 screws and cage nuts to the front rack posts. Make sure the switch is installed securely in the rack. See Figure2-12 and Figure2-13. As a best practice, use a torque of 30 kgf-cm (2.94 Nm) to fasten the M6 screws.

Figure2-12 Mounting the switch in the rack (with the wide flange of the rear mounting brackets inside the rack)

Rack-mounting by using front mounting brackets and long or super-short slide rails

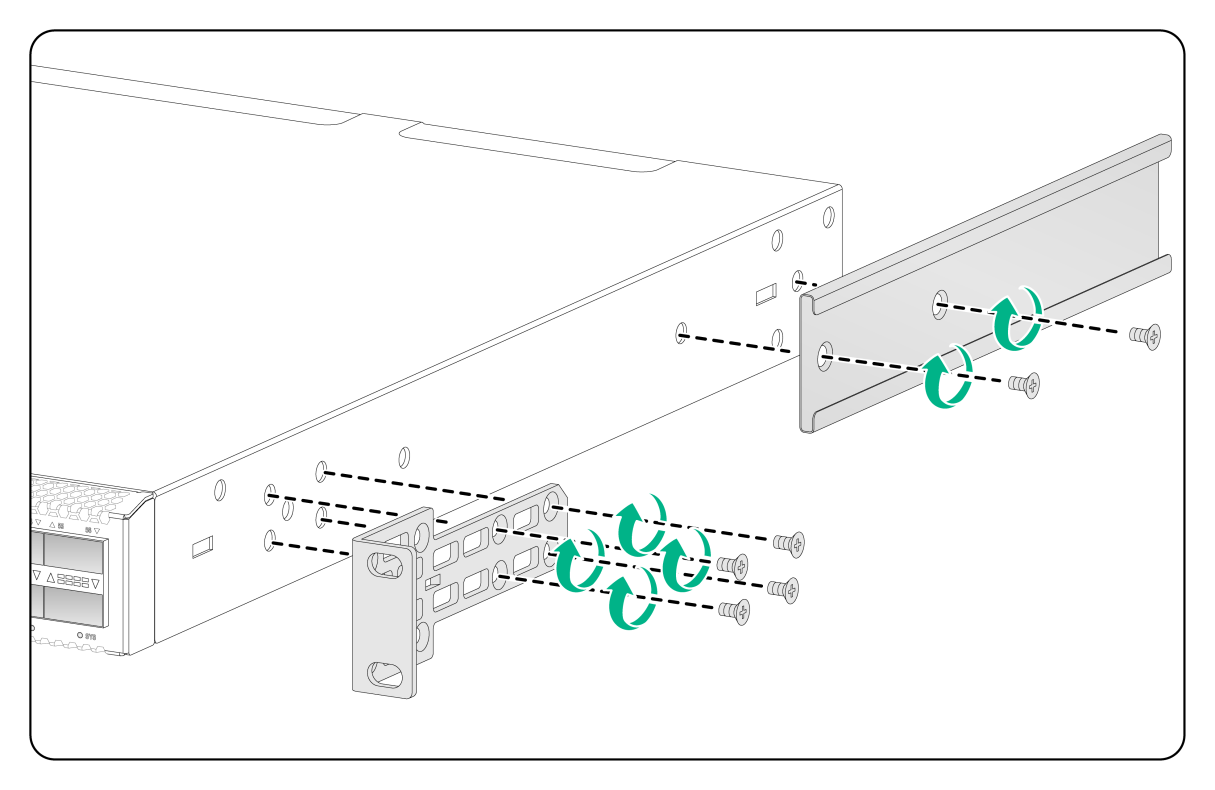

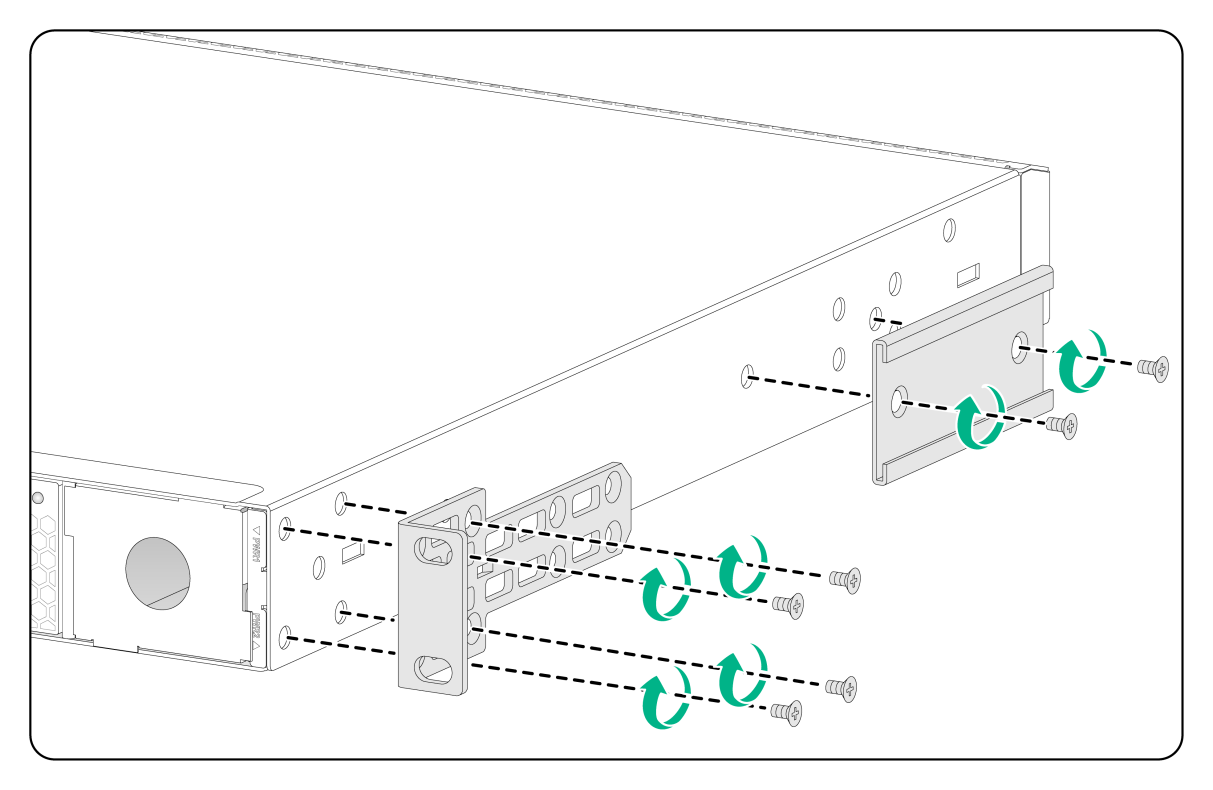

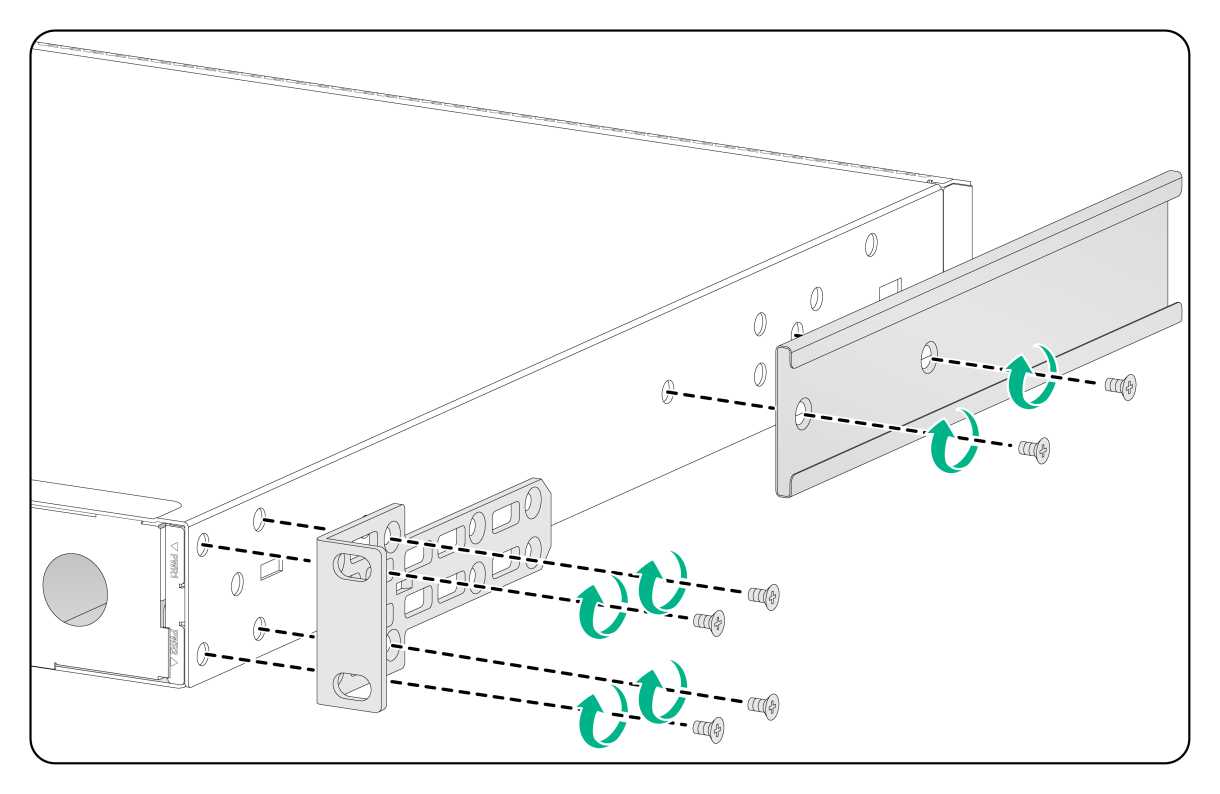

Attaching the chassis rails to the chassis

1. Place the wide flange of the mounting bracket against the chassis side panel. Align the mounting bracket installation holes with the appropriate screw holes in the chassis. Use the provided M4 screws to attach the mounting bracket to the chassis.

2. Place the chassis rail against the chassis side panel. Align the chassis rail installation holes with the screw holes. Use the provided M4 screws to attach the chassis rail to the chassis. See Figure2-14 to Figure2-19.

You can use super-short slide rails and long chassis rails to rack-mount the switch. Based on the rack depth, install the long chassis rails with the chassis rails not reaching out of the chassis, as shown in Figure2-15 through Figure2-18 or with the chassis rails reaching out of the chassis, as shown in Figure2-16 through Figure2-19.

Figure2-14 Attaching the front mounting brackets and chassis rails to the switch (port-side mounting position for the mounting brackets, long slide rails)

Figure2-15 Attaching the front mounting brackets and chassis rails to the switch (port-side mounting position for the mounting brackets, super-short slide rails, chassis rails not reaching out of the chassis)

Figure2-19 Attaching the front mounting brackets and chassis rails to the switch (power supply-side mounting position for the mounting brackets, super-short slide rails, chassis rails reaching out of the chassis)

|

|

NOTE: Secure the mounting brackets and chassis rails to both sides of the chassis in the same way. |

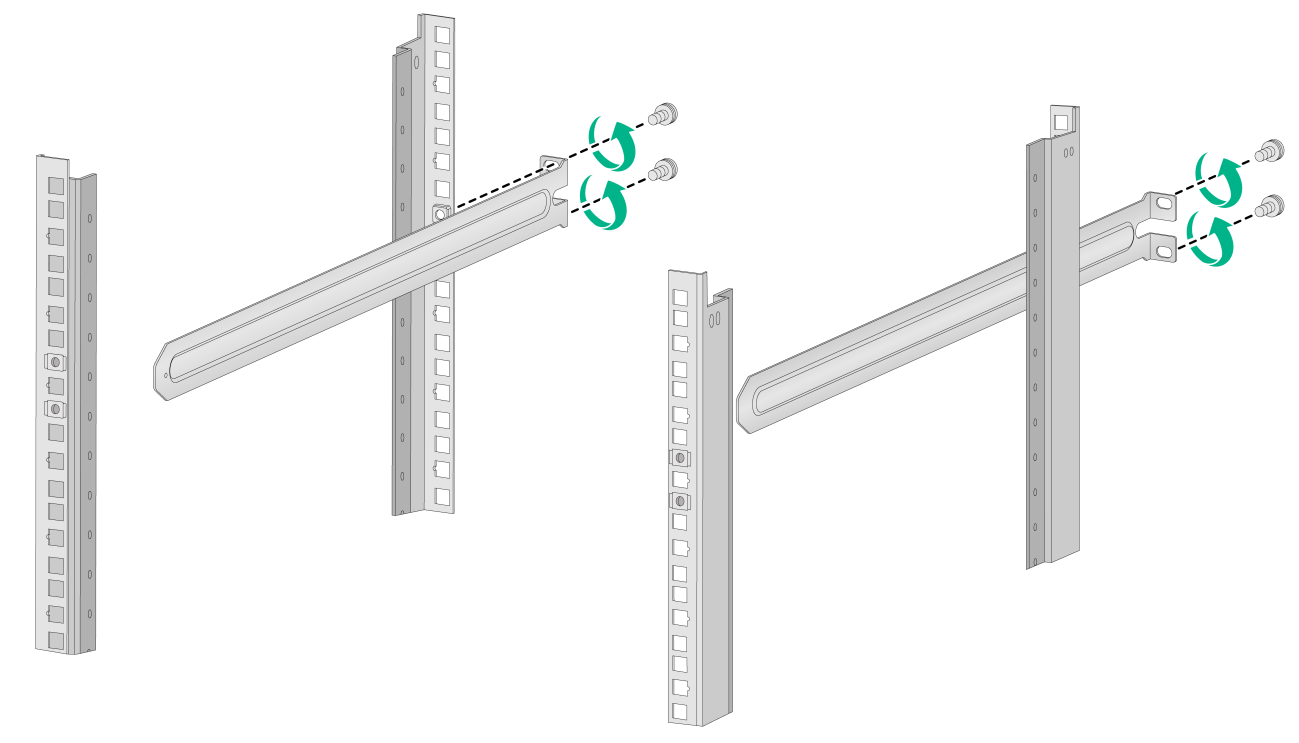

Attaching the long or super-short slide rails to the rack

The procedure is the same for attaching long and super-short slide rails to the rack. This section uses the long slide rails as an example.

To attach the slide rails to the rack:

1. Identify the slide rail installation position in the rack.

2. Install cage nuts in the mounting holes in the rack posts.

3. Align the screw holes in one slide rail with the cage nuts in a rear rack post. Use M6 screws to attach the slide rail to the post. See Figure2-20.

4. Repeat the preceding steps to attach the other slide rail to the other rear rack post.

Keep the two slide rails at the same height so the slide rails can attach into the chassis rails.

Figure2-20 Installing the long slide rails

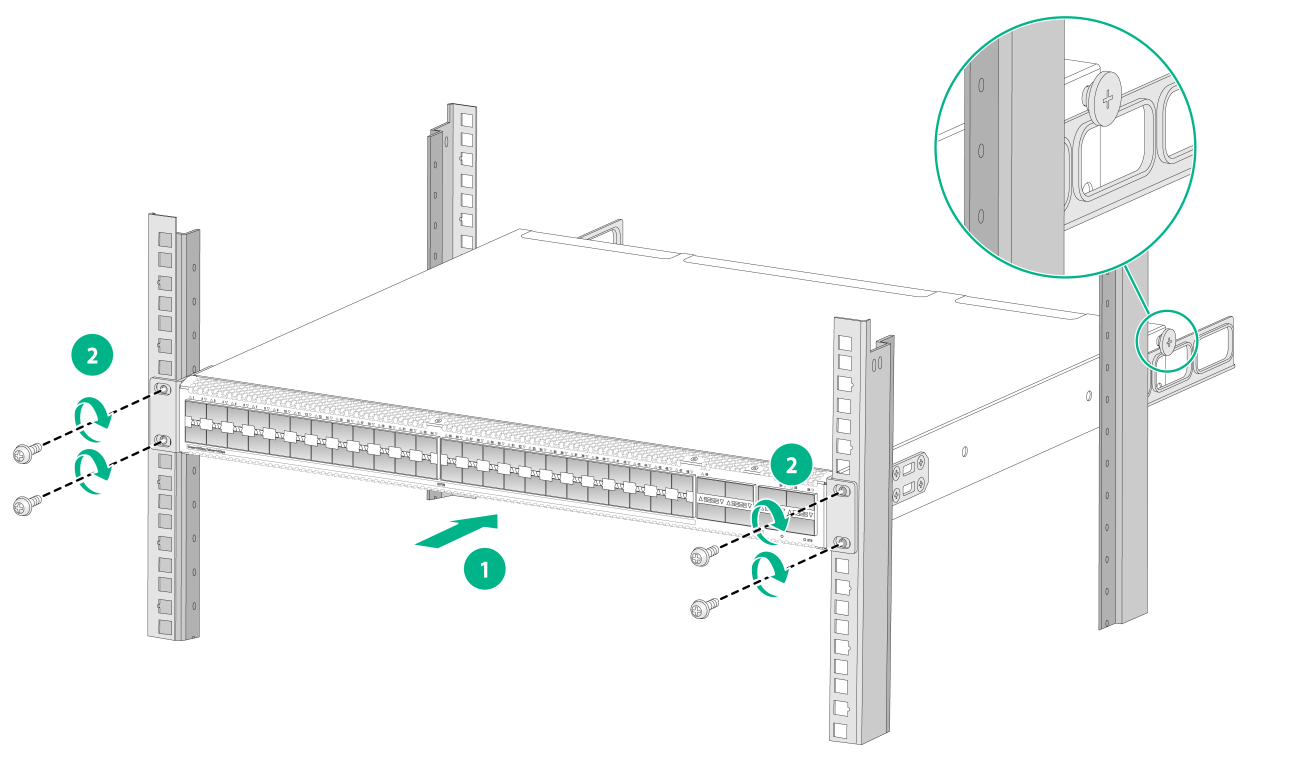

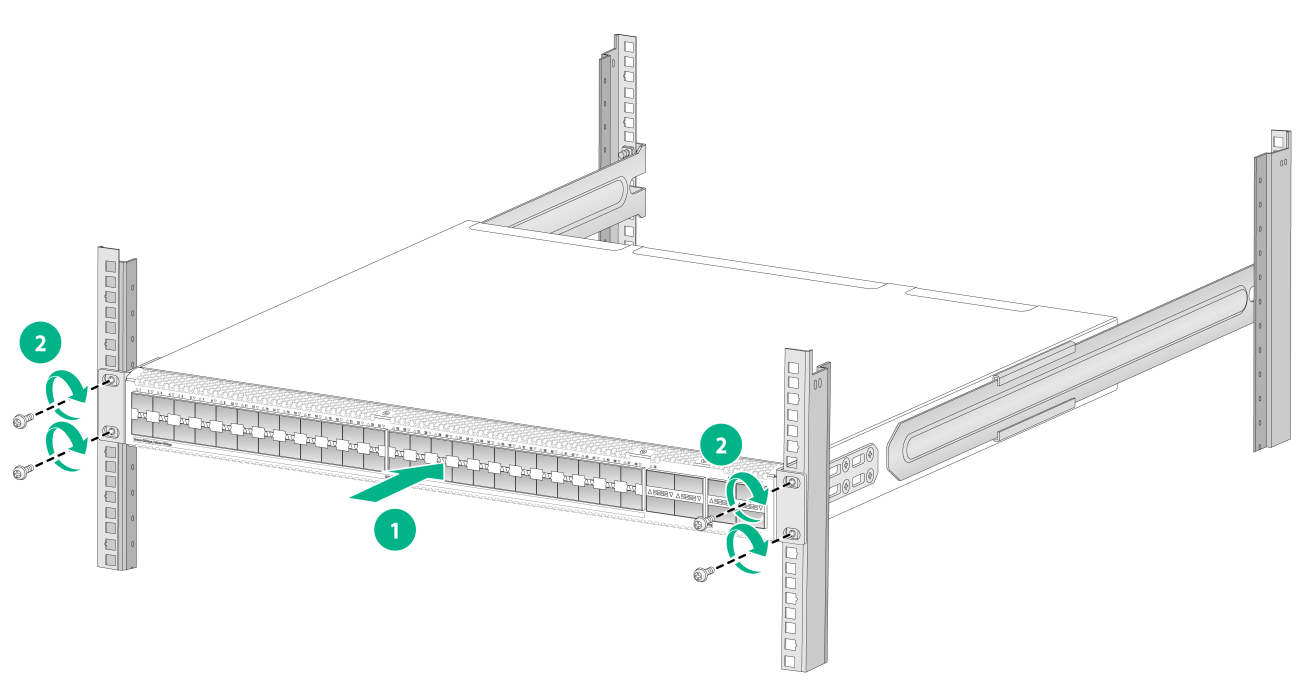

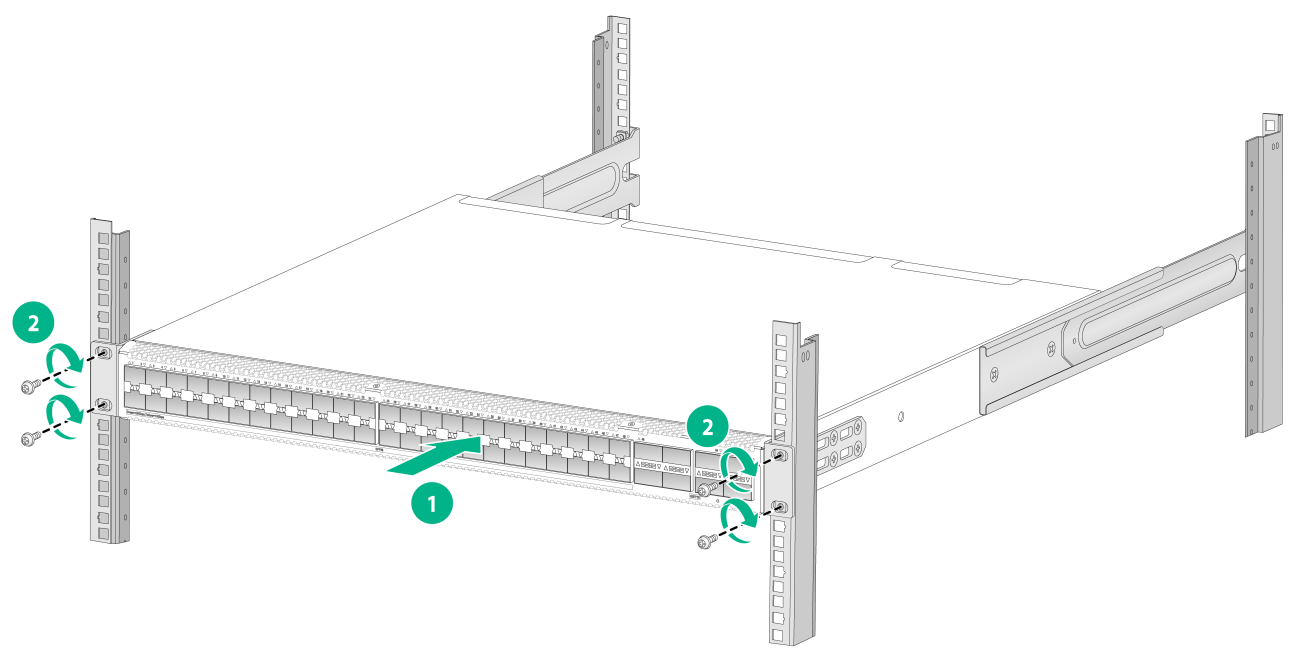

Mounting the switch in the rack

This task requires two people.

To mount the switch in the rack:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. Verify that the mounting brackets and chassis rails have been securely attached to the switch chassis. See "Attaching the chassis rails to the chassis."

3. Verify that the slide rails have been correctly attached to the rear rack posts. See "Attaching the long or super-short slide rails to the rack."

4. Attach cage nuts to the front rack posts and make sure they are at the same level as the slide rails.

5. One person performs the following operations:

a. Supporting the bottom of the switch, aligns the chassis rails with the slide rails on the rack posts.

b. Pushes the switch slowly to slide the chassis rails along the slide rails until the mounting brackets are flush with the rack posts.

|

IMPORTANT: If you use long slide rails to rack-mount the switch, make sure the front ends of the long slide rails reach out of the chassis rails for a maximum of 20 mm (0.79 in). If you use super-short slide rails to rack-mount the switch, make sure the front ends of the super-short slide rails reach inside the chassis rails for a minimum of 110 mm (4.33 in) after installation. |

6. Another person uses user-supplied M6 screws to attach the mounting brackets to the rack.

Figure2-22 Mounting the switch in the rack (port-side mounting position for the mounting brackets, super-short slide rails, chassis rails not reaching out of the chassis)

Figure2-23 Mounting the switch in the rack (port-side mounting position for the mounting brackets, super-short slide rails, chassis rails reaching out of the chassis)

Grounding the switch

|

CAUTION: Correctly connecting the grounding cable is crucial to lightning protection, ESD, and EMI protection. You must connect the grounding cable correctly and reliably for the switch. |

To protect against the following types of problems, use a grounding cable to connect the device to the earthing facility at the installation site:

· Bodily injury from electric shocks.

· Device and power and data line damages.

· Electrical fires, lightning strokes, electromagnetic coupling interferences, and ESD damages.

Choose an appropriate grounding method according to the installation environment.

|

|

NOTE: The grounding terminals in the following figures are for illustration only. |

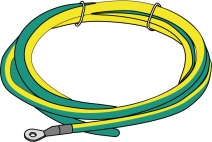

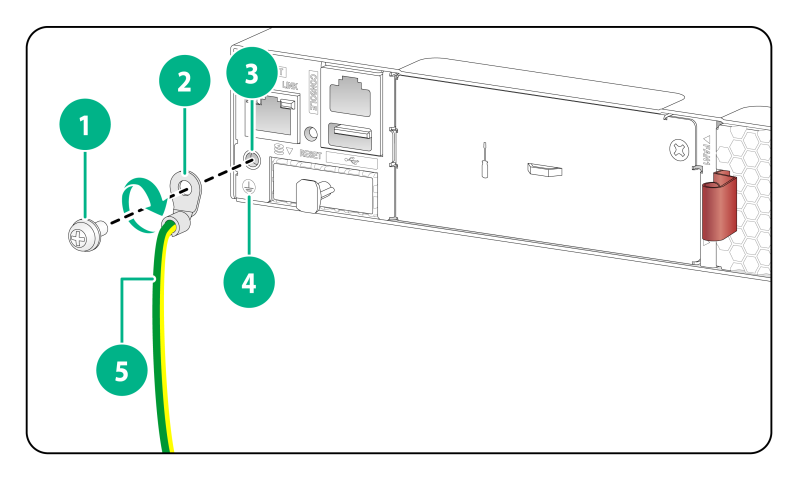

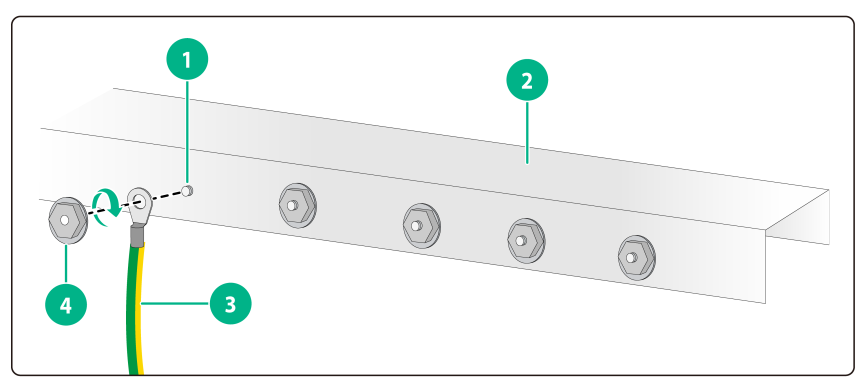

Grounding the switch by using a grounding strip

|

CAUTION: · Connect the grounding cable to the grounding strip in the equipment room. Do not connect it to a fire main or lightning rod. · To guarantee the grounding effect and avoid switch damage, use the grounding cable provided with the switch to connect the switch to a grounding strip in the equipment room. |

Connecting the grounding cable to the chassis

1. Remove the grounding screw from the grounding hole in the chassis.

2. Use the grounding screw to attach the ring terminal of the grounding cable to the grounding hole and fasten the grounding screw.

As a best practice, use a torque of 12 kgf-cm (1.18 Nm) to fasten the grounding screw.

|

IMPORTANT: Orient the grounding cable as shown in Figure2-24 so that you can easily install or remove the fan trays. |

Figure2-24 Connecting the grounding cable to the chassis

|

(1) Grounding screw |

(2) Ring terminal |

|

(3) Grounding sign |

(4) Grounding hole |

|

(5) Grounding cable |

|

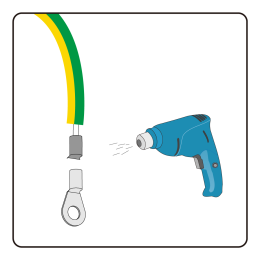

Connecting the grounding cable to a grounding strip

1. Remove a hex nut from the grounding strip.

2. Cut the grounding cable to a length according to the distance between the switch and the grounding strip.

3. Attach a ring terminal to the grounding cable:

a. Strip 5 mm (0.20 in) of insulation off the end of the grounding cable.

b. Slide the heat-shrink tubing onto the cable and insert the bare metal part into the end of the ring terminal.

c. Use a crimping tool to secure the metal part of the cable to the ring terminal.

d. Slide the heat-shrink tubing down the cable until the tube covers the joint.

e. Use a heat gun to shrink the tubing around the cable.

Figure2-25 Attaching a ring terminal to the grounding cable

4. Connect the ring terminal to the grounding post of the grounding strip, and fasten it with the removed hex nut.

Figure2-26 Connecting the grounding cable to a grounding strip

|

(1) Grounding post |

(2) Grounding strip |

|

(3) Grounding cable |

(4) Hex nut |

Installing/removing fan trays

|

CAUTION: The switch has multiple fan tray slots. To ensure good ventilation of the switch, follow these guidelines to install and remove fan trays: · The switch is provided with the fan tray slots empty. Before powering on the switch, make sure all fan tray slots have fan trays installed and the fan trays are the same model. · Make sure all slots have a module or filler panel installed when the switch is operating. · If multiple fan trays fail on an operating switch, do not remove the fan trays at the same time. Replace the fan trays one after another and finish replacing each fan tray within 3 minutes. |

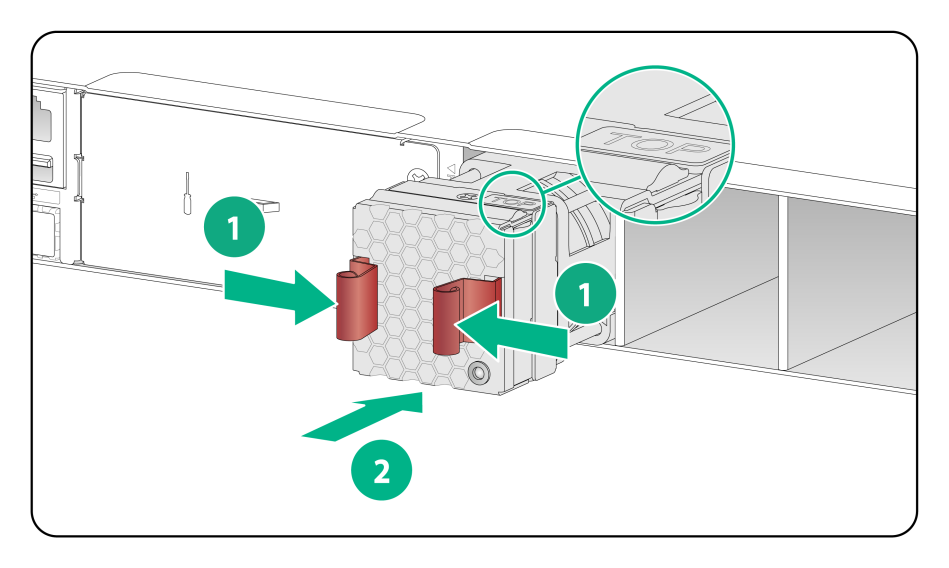

The installation and removal procedures are the same for the FAN-40F-1-A and FAN-40B-1-A fan trays. The following installation and removal procedures use the FAN-40B-1-A fan tray as an example.

Installing a fan tray

|

CAUTION: To prevent damage to the fan tray or the connectors on the backplane, insert the fan tray gently. If you encounter a hard resistance while inserting the fan tray, pull out the fan tray and insert it again. |

Select fan trays for the switch as needed. For the available fan trays and their specifications, see hardware information and specifications for the switch.

To install a fan tray:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. Unpack the fan tray and verify that the fan tray model is correct.

3. Orient the fan tray with the "TOP" mark on top. Grasp the handle of the fan tray with one hand and support the fan tray bottom with the other, and slide the fan tray along the guide rails into the slot until the fan tray is fully seated in the slot and has a firm contact with the backplane. See Figure2-27.

Figure2-27 Installing a FAN-40B-1-A fan tray in the switch

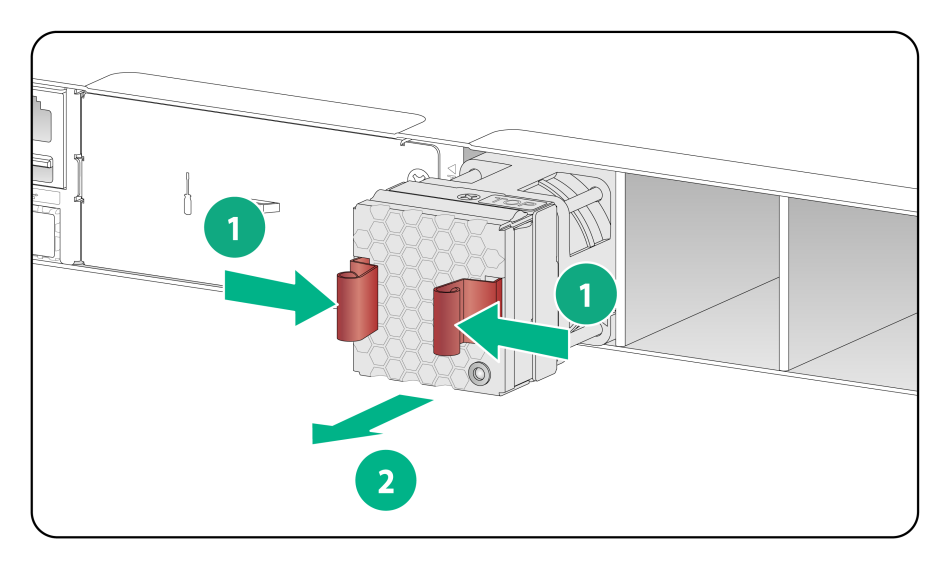

Removing a fan tray

|

WARNING! · Ensure electricity safety and never touch the rotating fans when you hot-swap a fan tray. · To prevent a fan from causing loud noise, do not touch the fan blades and rotation axis, even if the fan is not rotating. |

To remove a fan tray:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. Grasp the handle of the fan tray with one hand and pull the fan tray part way out of the slot. Support the fan tray bottom with the other and pull the fan tray completely out of the slot.

3. Put the removed fan tray in an antistatic bag.

Figure2-28 Removing a FAN-40B-1-A fan tray

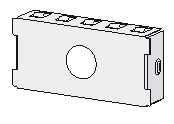

Installing/removing power supplies

|

WARNING! · To avoid bodily injury and device damage, strictly follow the procedures in Figure2-29 and Figure2-30 to install and remove a power supply. · Provide a separate circuit breaker for each power supply. |

Figure2-29 Installation procedure

The installation and removal procedures are the same for different models of power supplies. The following installation and removal procedures use a PSR450-12A1 power supply as an example.

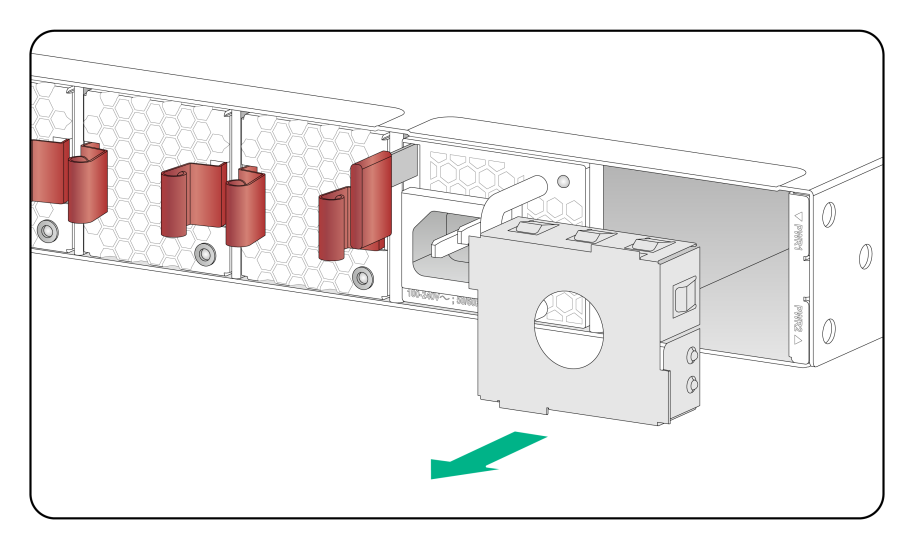

Installing a power supply

|

CAUTION: · Follow the forward inertia of the power supply when inserting it into the chassis, and make sure the power supply has firm contact with the connectors on the backplane. · To prevent damage to the connectors inside the switch chassis, insert the power supply gently. If you encounter a hard resistance while inserting the power supply, pull out the power supply and insert it again. |

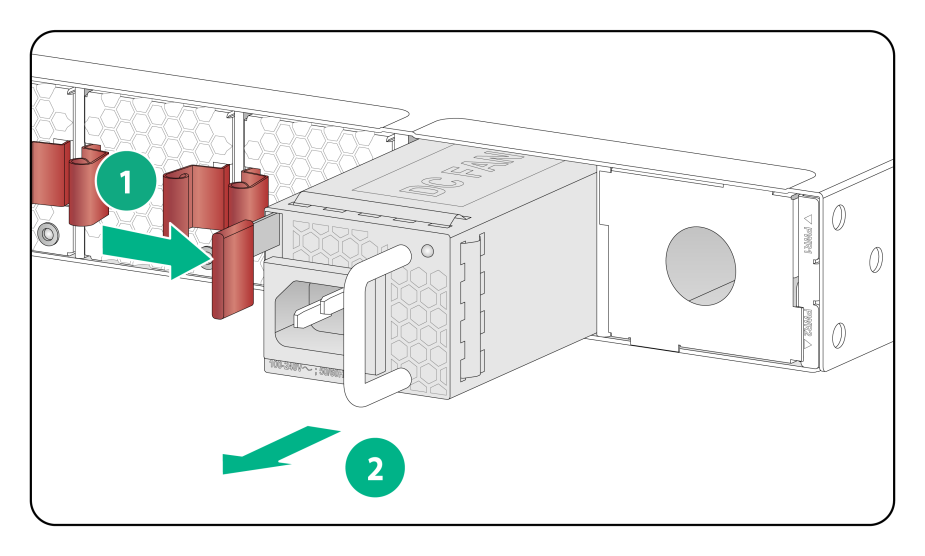

To install a power supply:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

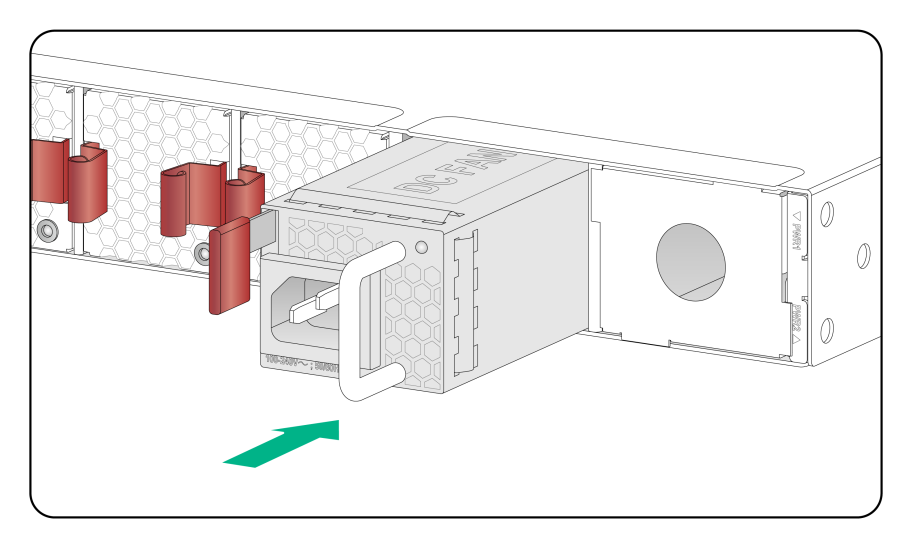

2. Remove the filler panel, if any, from the target power supply slot, as shown in Figure2-31.

Figure2-31 Removing a filler panel

3. Unpack the power supply and verify that the power supply model is correct.

4. Correctly orient the power supply with the words on the power supply upward. Grasp the handle of the power supply with one hand and support its bottom with the other, and slide the power supply slowly along the guide rails into the slot.

The slot is foolproof. If you cannot insert the power supply into the slot, re-orient the power supply rather than use excessive force to push it in.

Figure2-32 Installing a power supply

Removing a power supply

|

CAUTION: When the switch has two power supplies in 1+1 redundancy mode, removing one power supply does not affect the operation of the switch. When the switch has only one power supply installed, removing the power supply powers off the switch. |

To remove a power supply:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. Disconnect the power cord from the power source and power supply.

3. Holding the handle on the power supply with one hand, press the latch on the power supply towards the handle direction with your thumb, and pull the power supply part way out of the slot. Supporting the power supply bottom with the other, slowly pull out the power supply.

4. Put the removed power supply on an antistatic mat or in its original package.

5. If you are not to install a new power supply, install a filler panel in the slot.

Figure2-33 Removing a power supply

Connecting the power cords

|

WARNING! Provide a circuit breaker for each power input. When you connect a power cord, make sure the circuit breaker is switched off. |

Connecting the power cord for a PSR450-12A/PSR450-12A1 power supply

The power cord connection procedure is the same for the PSR450-12A and PSR450-12A1 power supplies. The following procedure uses a PSR450-12A1 power supply as an example.

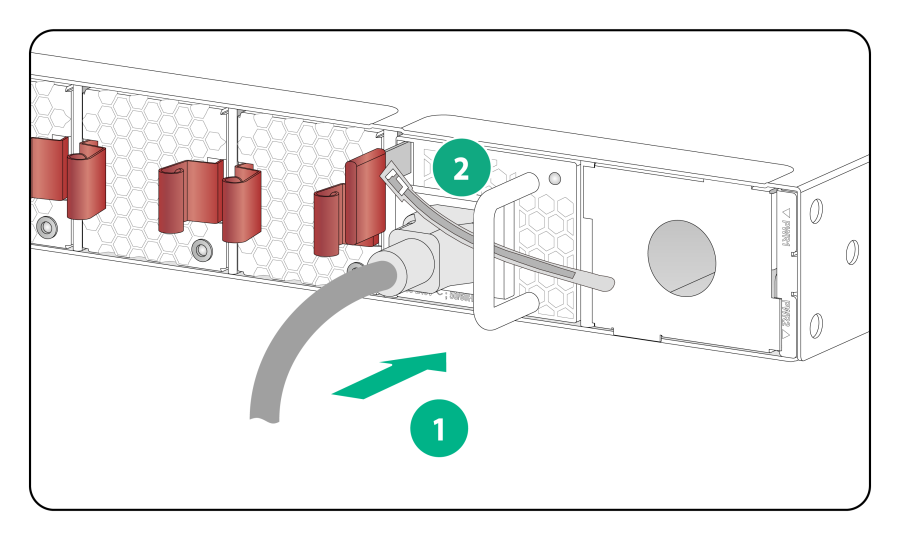

To connect the power cord for a PSR450-12A1 power supply:

1. Insert the female connector of the power cord supplied with the power supply into the power receptacle on the power supply.

2. Use a releasable cable tie to secure the power cord to the handle of the power supply, as shown in Figure2-34.

3. Connect the other end of the power cord to a power source.

Figure2-34 Connecting a power cord to the PSR450-12A1 power supply (1)

Figure2-35 Connecting a power cord to the PSR450-12A1 power supply (2)

Connecting the power cord for a PSR450-12AHD power supply

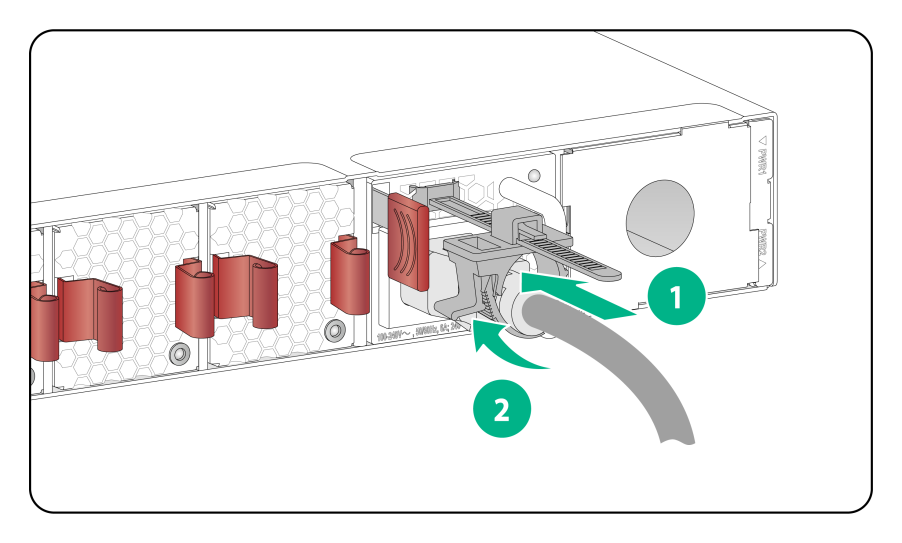

1. Slide the cable clamp onto the tie mount on the power supply, as shown in Figure2-36.

2. Connect the female connector of the power cord to the power receptacle on the power supply. Close the cable clamp and slide it forward until it is flush against the edge of the female connector. See Figure2-37.

3. Connect the other end of the power cord to a power source.

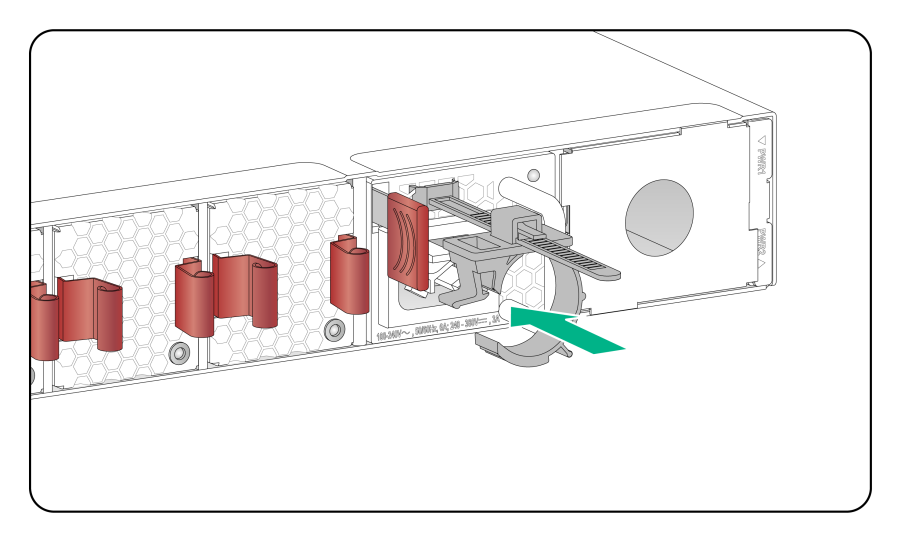

Figure2-36 Connecting the power cord for a PSR450-12AHD power supply (1)

Figure2-37 Connecting the power cord for a PSR450-12AHD power supply (2)

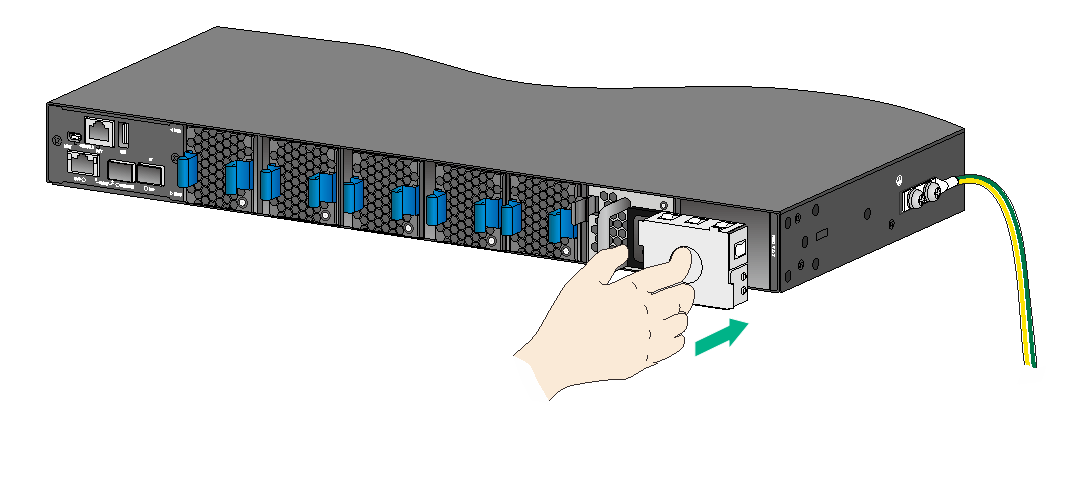

Connecting the DC power cord for a PSR450-12D power supply

|

CAUTION: · To use a –48 VDC power source to supply power for the power supply, use the DC power cord supplied with the power supply. · When you use a –48 VDC power source to supply power, identify the positive (+) and negative (-) marks on the two wires to avoid connection mistakes. |

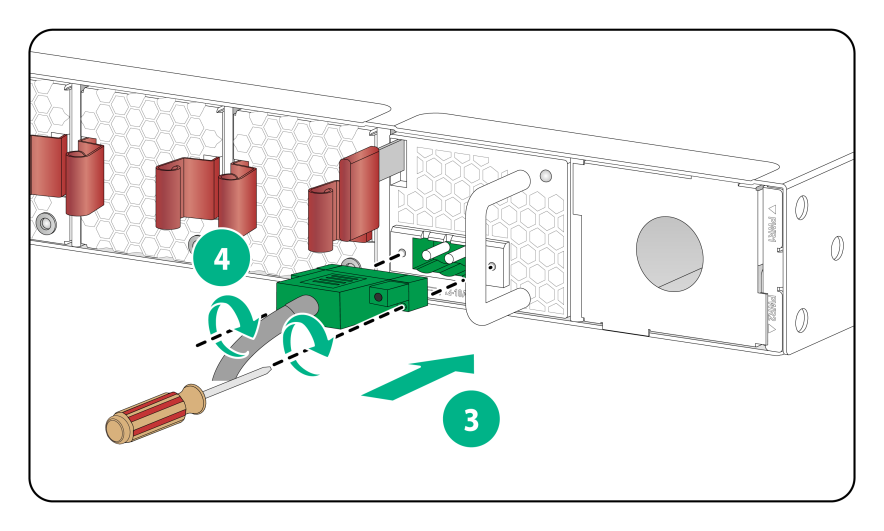

To connect the DC power cord for a PSR450-12D power supply:

1. Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2. As shown by callout 1 and callout 2 in Figure2-38, use a flat-head screwdriver to loosen the mounting screws on the receptacle cover, and then remove the receptacle cover.

3. As shown by callout 3 in Figure2-39, correctly orient the power cord connector and insert it into the power receptacle. The power receptacle and power cord connector have disorientation rejection designs. If you cannot insert the connector into the receptacle, re-orient the connector rather than use excessive force to push it in.

4. As shown by callout 4 in Figure2-39, use a flat-head screwdriver to fasten the screws on the power cord connector to secure the connector to the receptacle.

5. Connect the other end of the power cord to a –48 VDC power source.

Figure2-38 Connecting the DC power cord for a PSR450-12D power supply (1)

Figure2-39 Connecting the DC power cord for a PSR450-12D power supply (2)

Verifying the installation

After you complete the installation, verify that:

· There is enough space for heat dissipation around the switch, and the rack is stable.

· The grounding cable is securely connected.

· The correct power source is used.

· The power cords are correctly connected.

· All the interface cables are cabled indoors. The switch does not support cabling outdoors.

3 Accessing the switch for the first time

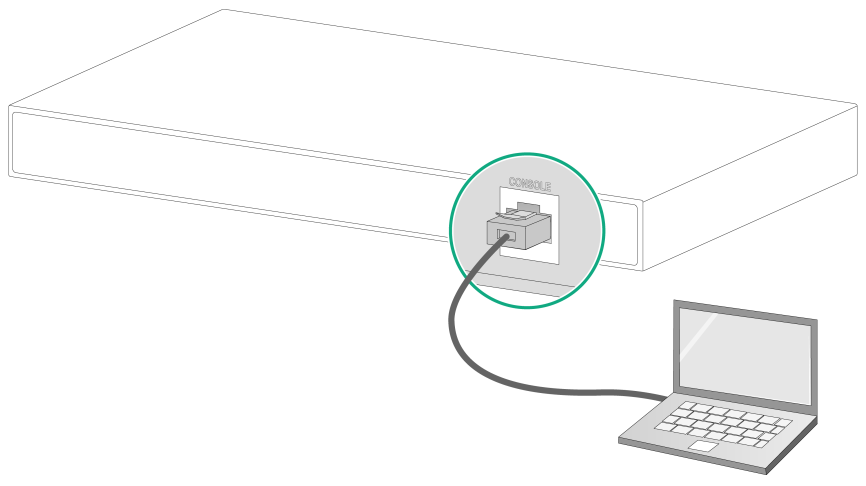

Connecting the switch to a configuration terminal

You can connect the switch to a configuration terminal only by using the serial console port.

In Figure3-1, the switch is connected to a configuration terminal (PC as an example) from the serial console port.

Figure3-1 Connecting the switch to a configuration terminal

Connecting a DB9-to-RJ45 console cable

|

CAUTION: Follow these guidelines when you connect a DB9-to-RJ45 console cable: · Identify the mark on the serial console port and make sure you are connecting to the correct port. · The serial ports on PCs do not support hot swapping. To connect a PC to an operating switch, first connect the PC end. To disconnect a PC from an operating switch, first disconnect the switch end. |

A DB9-to-RJ45 serial console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for connecting to the serial console port of the switch, and a DB-9 female connector at the other end for connecting to the serial port on a configuration terminal.

Figure3-2 DB9-to-RJ45 console cable

Table3-1 DB9-to-RJ45 console cable signal pinout

|

RJ-45 |

Signal |

DB-9 |

Signal |

|

1 |

RTS |

8 |

CTS |

|

2 |

DTR |

6 |

DSR |

|

3 |

TXD |

2 |

RXD |

|

4 |

SG |

5 |

SG |

|

5 |

SG |

5 |

SG |

|

6 |

RXD |

3 |

TXD |

|

7 |

DSR |

4 |

DTR |

|

8 |

CTS |

7 |

RTS |

To connect the switch to a configuration terminal (for example, a PC) by using a DB9-to-RJ45 console cable:

1. Plug the DB-9 female connector of the DB9-to-RJ45 console cable to the serial port on the PC.

2. Connect the RJ-45 connector to the serial console port on the switch.

Connecting a USB-to-RJ45 console cable

|

IMPORTANT: · To use a USB-to-RJ45 console cable to connect the switch to a configuration terminal, first download and install the USB-to-RJ45 console driver on the configuration terminal and then connect the USB-to-RJ45 console cable to the configuration terminal. · If you have connected a USB-to-RJ45 console cable to the configuration terminal before installing the driver, remove and reconnect the USB-to-RJ45 console cable to the configuration terminal after driver installation. |

The following installs the driver on a Windows operating system. To install the driver on other operating systems, see the installation guide in the driver compression package named by using the corresponding operating system.

To connect the switch to a configuration terminal by using a USB-to-RJ45 console cable:

1. Click the following link, or copy it to the address bar on your browser and download the USB-to-RJ45 console driver.

http://www.h3c.com/en/home/USB_to_RJ45_Console/

2. View the TXT file Read me in the Windows folder to identify whether the Windows operating system on the configuration terminal supports the driver.

3. If the Windows operating system supports the driver, install PL23XX-M_LogoDriver_Setup_v200_20190815.exe.

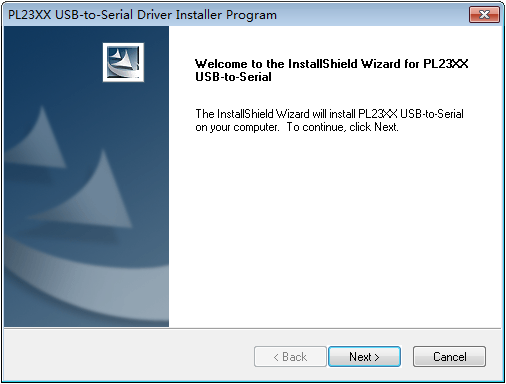

4. Click Next on the welcome page of the driver installation wizard.

Figure3-3 Driver installation wizard

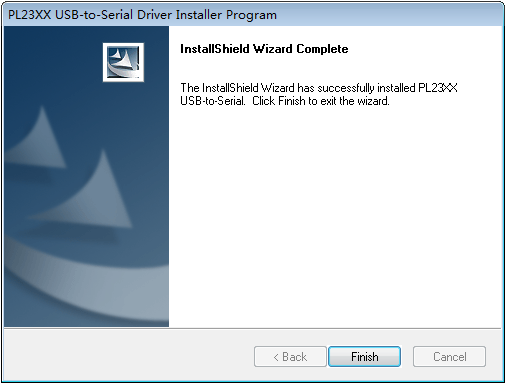

5. Click Finish after the drive installation is completed.

Figure3-4 Finishing the driver installation

6. Connect the standard USB connector of the cable to the USB port of the configuration terminal.

7. Connect the RJ-45 connector of the cable to the console port of the switch.

Setting terminal parameters

To configure and manage the switch through the console port, you must run a terminal emulator program, TeraTermPro or PuTTY, on your configuration terminal. You can use the emulator program to connect a network device, a Telnet site, or an SSH site. For more information about the terminal emulator programs, see the user guides for these programs

Configure the terminal parameters as follows:

· Bits per second—9600.

· Data bits—8.

· Stop bits—1.

· Parity—None.

· Flow control—None.

Powering on the switch

1. Before powering on the switch, verify that the following conditions are met:

¡ All the fan tray slots have a fan tray installed.

¡ The power cords are connected correctly.

¡ The input power voltage is as required by the switch.

¡ The console cable is connected correctly.

¡ The configuration terminal (a PC, for example) has started, and its serial port settings are consistent with the console port settings on the switch.

2. Power on the switch.

During the startup process, you can access BootWare menus to perform tasks such as software upgrade and file management. The BootWare interface and menu options vary by software version. For more information about BootWare menu options, see the software-matching release notes for the device.

3. After the startup completes, you can access the CLI to configure the switch.

For more information about the configuration commands and CLI, see the command references and configuration guides for the switch.

4 Maintenance and troubleshooting

Power supply failure

Symptom

The power supply status LED on a power supply is not steady green.

For more information about the LEDs on a power supply, see H3C PSR450 Power supply Series User Manual.

Solution

To resolve the issue:

1. Verify that the power cord is connected correctly.

2. Verify that the power source is as required by the switch.

3. Verify that the operating temperature of the switch is in the acceptable range and the power supply has good ventilation.

4. If the issue persists, contact H3C Support.

To replace a power supply, see "Installing/removing power supplies."

Fan tray failure

|

CAUTION: If multiple fan trays fail when the switch is operating, do not remove the fan trays at the same time. Replace the fan trays one after another and finish replacing each fan tray within 3 minutes. |

The switch uses removable fan trays. Use the LED on a fan tray to identify the fan tray status. If a fan tray fails, see "Installing/removing fan trays" to replace the fan tray. If the issue persists, contact H3C Support.

Configuration terminal display issues

No display

Symptom

The configuration terminal displays nothing when the switch is powered on.

Solution

To resolve the issue:

1. Verify that the power system is operating correctly.

2. Verify that the console cable is connected correctly.

3. Verify that the console cable does not have any issues and the terminal settings are correct.

4. If the issue persists, contact H3C Support.

Garbled display

Symptom

The configuration terminal has a garbled display.

Solution

To resolve the issue:

1. Verify that the following settings are configured for the terminal:

¡ Baud rate—9,600.

¡ Data bits—8.

¡ Parity—None.

¡ Stop bits—1.

¡ Flow control—None.

2. If the issue persists, contact H3C Support.