- Table of Contents

- Related Documents

-

| Title | Size | Download |

|---|---|---|

| 01-Text | 13.52 MB |

General safety recommendations

Examining the installation site

Installing the router in a 19-inch rack

Installing the router by using mounting brackets and a rack shelf

Installing the router by using mounting brackets and slide rails

Installing an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU

Installing a FIP module and an air deflector

(Optional) Installing an air deflector

Installing a SAP/OAP/switching fabric module

Installing a HIM/MIM/MIC/MIC-X interface module

Assembling a MIC-X adapter module and MIC interface module into a MIC-X interface module

Installing an interface module

3 Installing optional components

Installing a fiber management tray

Installing a lightning protector for a network port

Connecting the AC power supply to a power strip with lightning protection

Connecting a serial port cable

Connecting a serial port cable

Logging in from the console port/USB console port

Connecting the console port by using a console cable

Connecting the USB console port by using a USB cable

Logging in to the router through Telnet

Replacing an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU

Replacing a SAP/OAP/switching fabric module

Replacing a transceiver module

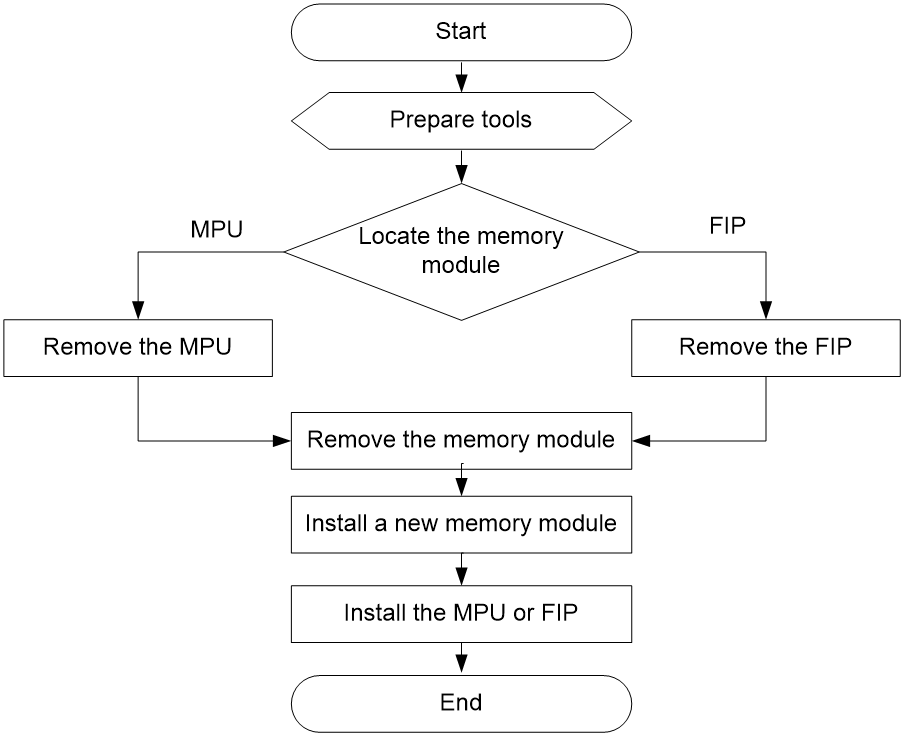

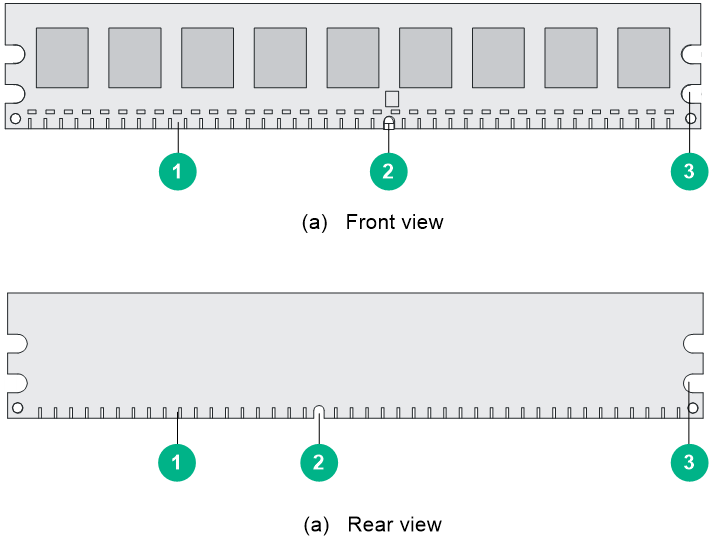

When to replace a memory module

7 Hardware management and maintenance

Displaying hardware information for the router

Displaying the software and hardware version information for the router

Displaying the operational statistics for the router

Displaying detailed information about a module

Displaying the electrical label information for a module

Displaying the CPU usage of a module

Displaying the memory usage of a module

Displaying the CF card information

Displaying the operational status of the fan

Displaying the operational status of power supplies

Displaying the alarming thresholds of a module

Port configuration and management

Displaying transceiver module information and alarming information

Saving the current configuration of the router

ALM LED is steady on or flashes

No response from the serial port

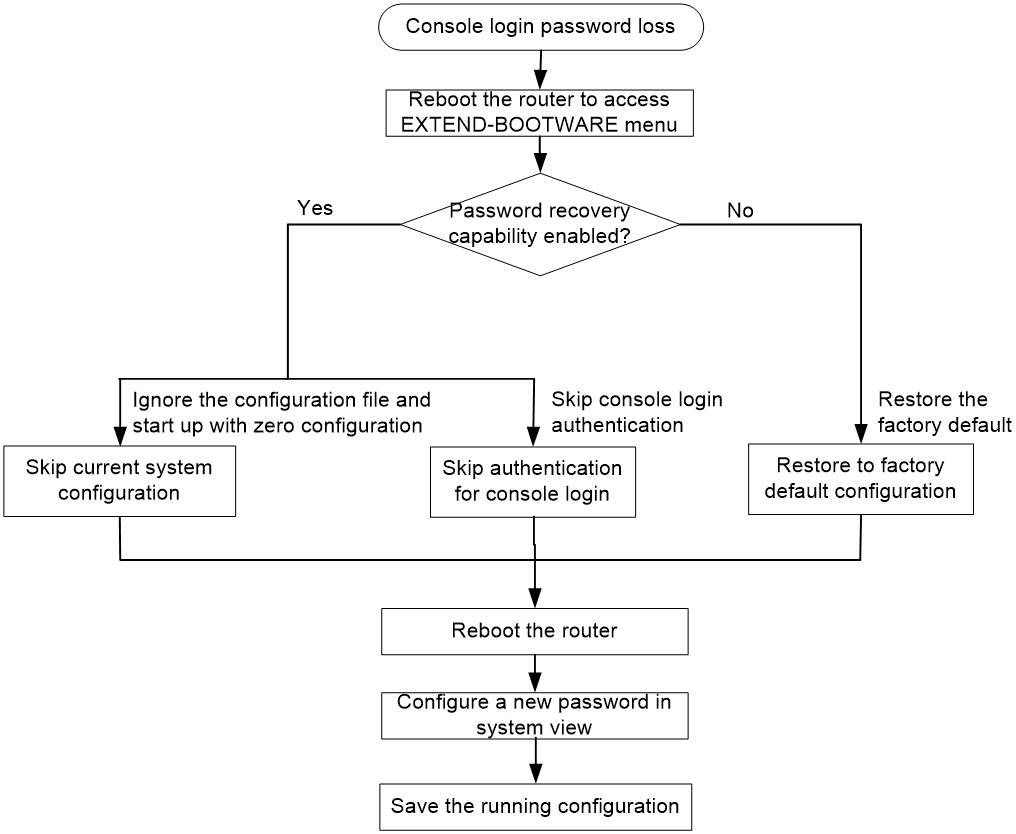

Dealing with console login password loss

Examining the state of password recovery capability

Skipping current system configuration

Skipping authentication for console login

Restoring to factory default configuration

Interface module, cable, and connection failure

No response from the serial port of the MPU

System software image file missing errors

1 Preparing for installation

Table1-1 shows the model and product code matrix for the H3C SR6616 router.

Table1-1 Router model and product code matrix

|

Model (on the front panel) |

Product code |

|

H3C SR6616 |

RT-SR6616-H3 |

|

RT-SR6616-DS-H3 |

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety recommendations before installation. Note that the recommendations do not cover every possible hazardous condition.

Safety symbols

When reading this document, note the following symbols:

![]() WARNING means an alert that calls attention to important

information that if not understood or followed can result in personal injury.

WARNING means an alert that calls attention to important

information that if not understood or followed can result in personal injury.

![]() CAUTION means an alert that calls attention to important

information that if not understood or followed can result in data loss, data

corruption, or damage to hardware or software.

CAUTION means an alert that calls attention to important

information that if not understood or followed can result in data loss, data

corruption, or damage to hardware or software.

General safety recommendations

· Keep the chassis and installation tools away from walk areas.

· Make sure the ground is dry and flat and anti-slip measures are in place.

· Remove all the external cables (including power cords) before moving the chassis.

Electricity safety

· Locate the emergency power-off switch in the room before installation. Shut the power off at once in case accident occurs.

· Make sure the router has been reliably grounded.

· Do not open or close the chassis cover when the router is powered on.

· Use an uninterrupted power supply (UPS).

· If there are two power inputs, disconnect the two power inputs to power off the router.

· Do not work alone when the router has power.

· Always verify that the power has been disconnected.

Laser safety

|

WARNING! · The router is a Class 1 laser device. · Disconnected optical fibers or transceiver modules might emit invisible laser light. Do not stare into beams or view directly with optical instruments when the router is operating. |

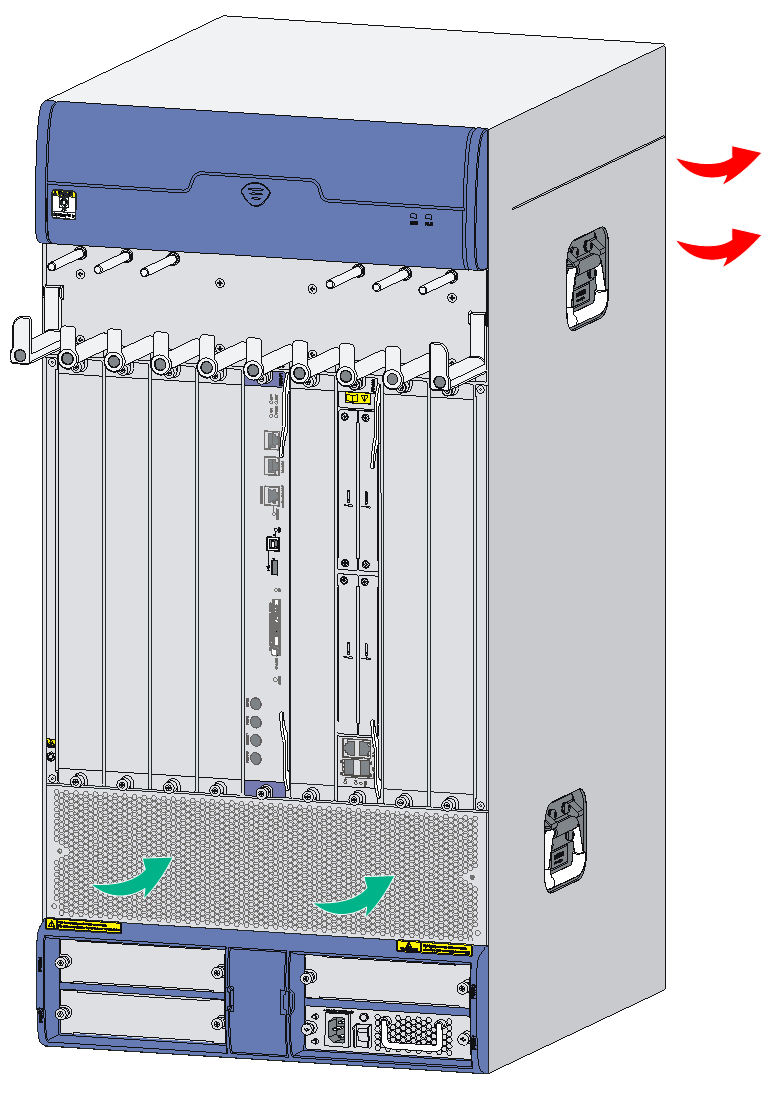

Router moving

|

CAUTION: Do not hold the handle of the fan tray or power supply, the handle on the rear cover of the chassis, or the air vents of chassis to move the router. Doing so might cause equipment damage or even bodily injury. |

When moving the router, follow these guidelines:

· When moving the router, hold the handles at both sides of the chassis.

· Use at least two people to move the router.

· Move the router carefully.

Examining the installation site

The router can be used only indoors. For the router to operate correctly and to have a long service lifetime, make sure the installation site meets the requirements described in the following subsections.

Weight support

Make sure the floor can support the total weight of the router and accessories (such as the rack and interface modules). For the weights of the router and accessories, see H3C SR6616 Routers Hardware Information and Specifications.

Temperature

If the temperature in the equipment room is too high, too low, or changes dramatically, the router reliability will be reduced and its service lifetime will be shortened. For long-term, highly available operation of the router, make sure temperature in the equipment room meets the requirements described in Table1-2.

Table1-2 Temperature requirements

|

Item |

Temperature |

|

Operating Temperature |

0°C to 45°C (32°F to 113°F) |

|

Storage Temperature |

–40°C to +70°C (–40°F to +158°F) |

Humidity

Maintain appropriate humidity in your equipment room, as described in Table1-3.

· Lasting high relative humidity can cause poor insulation, electricity leakage, mechanical property change of materials, and metal corrosion.

· Lasting low relative humidity can cause washer contraction and ESD and bring problems including loose screws and circuit failure.

Table1-3 Humidity requirements

|

Item |

Humidity |

|

Operating humidity (noncondensing) |

10% RH to 95% RH |

|

Storage humidity (noncondensing) |

5% RH to 95% RH |

Cleanliness

Dust buildup on the chassis might result in electrostatic adsorption, which causes poor contact of metal components and contact points, especially when indoor relative humidity is low. In the worst case, electrostatic adsorption can cause communication failure.

Table1-4 Router requirement for cleanliness

|

Substance |

Particle diameter |

Concentration limit |

|

Dust particles |

≥ 0.5 µm |

≤ 1.8 × 107 particles/m3 |

Corrosive gases can accelerate corrosion and aging of metal components. Make sure the corrosive gases do not exceed the concentration limits as shown in Table1-5.

Table1-5 Corrosive gas concentration limits

|

Gas |

Average concentration (mg/m3) |

Maximum concentration (mg/m3) |

|

SO2 |

0.3 |

1.0 |

|

H2S |

0.1 |

0.5 |

|

Cl2 |

0.1 |

0.3 |

|

HCI |

0.1 |

0.5 |

|

HF |

0.01 |

0.03 |

|

NH3 |

1.0 |

3.0 |

|

O3 |

0.05 |

0.1 |

|

NOX |

0.5 |

1.0 |

Cooling system

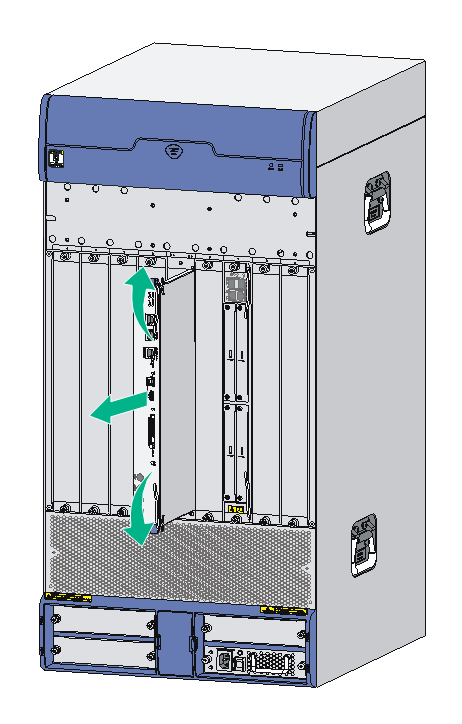

The router has a horizontally-oriented fan tray slot at the top and uses bottom to top airflow for heat dissipation.

To ensure good ventilation, the following requirements must be met:

· Leave a minimum clearance of 10 cm (3.94 in) at the inlet and outlet air vents.

· The installation site has a good cooling system.

Figure1-1 Airflow

ESD prevention

|

CAUTION: Make sure the resistance reading between human body and the ground is in the range of 1 to 10 megohms (Mohms). |

To prevent electrostatic discharge (ESD), note the following guidelines:

· Make sure the router and the floor are reliably grounded.

· Take dust-proof measures for the equipment room.

· Maintain the humidity and temperature in the acceptable range.

· Always wear an ESD wrist strap when touching a circuit board or transceiver module.

· Place the removed memory module, CF card, or HIM/MIM/MIC/MIC-X on an antistatic workbench, with the face upward, or put it into an antistatic bag.

· Touch only the edges, instead of electronic components when observing or moving a removed memory module, CF card, or HIM/MIM/MIC/MIC-X.

To attach the ESD wrist strap:

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Insert the ESD wrist strap into the specially designed hole on the router chassis or attach it to the grounding screw of the chassis with the alligator clips.

4. Make sure the rack is reliably grounded.

Figure1-2 Attaching an ESD wrist strap

|

(1) ESD wrist strap |

(2) Lock |

(3) Alligator clip |

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the router and application system, adversely affect the router in the following ways:

· A conduction pattern of capacitance coupling.

· Inductance coupling.

· Electromagnetic wave radiation.

· Common impedance (including the grounding system) coupling.

To prevent EMI, use the following guidelines:

· Take effective measures to filter interference from the power grid.

· Separate the grounding facility of the router from the grounding facility and lightning protection facility of the other electrical devices as far as possible.

· Use electromagnetic shielding, for example, shielded interface cables, when necessary.

Lightning protection

To protect the router from lightning better, perform the following tasks:

· Make sure the grounding cable of the chassis is reliably grounded. For information about how to connect the grounding cable, see "Grounding the router."

· Make sure the grounding terminal of the AC power receptacle is reliably grounded.

· Install a lightning protector at the input end of the power supply to enhance the lightning protection capability of the power supply.

· Install a special lightning protector at the input end of outdoor signal lines (for example, E1/T1 line) to which interface modules of the router are connected to enhance the lightning protection capability.

For more information about how to install a lightning protector and surge protector, see "Connecting the AC power supply to a power strip with lightning protection" and "Installing a surge protector."

Space

For easy installation and maintenance, follow these space requirements:

· Reserve a minimum of 1 m (3.28 ft) of clearance between the rack and walls or other devices.

· For heat dissipation, make sure the headroom in the equipment room is not less than 3 m (9.84 ft).

· Make sure the rack has enough space to accommodate the router. See Table1-6 for rack requirements. For more information about chassis dimensions, see H3C SR6616 Routers Hardware Information and Specifications.

Table1-6 Router dimensions and rack requirements

|

Model |

Chassis dimensions |

Rack requirements |

|

SR6616 AC |

· Height—886 mm (34.89 in)/20 RU · Width—436 mm (17.17 in) · Depth—591 mm (23.27 in) ¡ 480 mm (18.90 in) for the chassis ¡ 102 mm (4.02 in) for the cable management brackets at the chassis front ¡ 11 mm (0.43 in) for the grounding screw at the chassis rear |

· A minimum of 0.8 m (2.62 ft) in depth (recommended) · A minimum of 102 mm (4.02 in) between the front rack posts and the front door · A minimum of 490 mm (19.29 in) between the front rack posts and the rear door |

|

SR6616-DS |

· Height—886 mm (34.89 in)/20 RU · Width—436 mm (17.17 in) · Depth—591 mm (23.27 in) ¡ 480 mm (18.90 in) for the chassis ¡ 102 mm (4.02 in) for the cable management brackets at the chassis front ¡ 11 mm (0.43 in) for the grounding screw at the chassis rear |

· A minimum of 0.8 m (2.62 ft) in depth (recommended) · A minimum of 102 mm (4.02 in) between the front rack posts and the front door · A minimum of 490 mm (19.29 in) between the front rack posts and the rear door |

|

|

NOTE: The signal cables and power cords are routed through the front of the chassis. If you use power cords that has a conductor cross-section area of a minimum of 16 sq mm (0.02 sq in), leave more space between the front rack posts and the front door as appropriate. |

Power supply

· Make sure the power supply system at the installation site is stable and meets the requirements of the power supplies, including the rated input voltage.

· Select power supplies based on the power consumption of the cards and fan trays. For more information about system power consumption and technical specifications of power supplies, see H3C SR6616 Routers Hardware Information and Specifications.

Installation accessories

|

Grounding cable |

ESD wrist strap |

Cable tie |

Mounting brackets |

|

|

|

||

|

M6 screws (provided with the SR6616-DS and user-supplied for other router models) |

Cage nuts (provided with the SR6616-DS and user-supplied for other router models) |

|

|

Pre-installation checklist

Table1-7 Pre-installation checklist

|

Item |

Requirements |

Result |

|

|

Installation site |

Ventilation |

· There is a minimum clearance of 10 cm (3.9 in) around the inlet and outlet vents for heat dissipation of the router chassis. · A ventilation system is available at the installation site. |

|

|

Temperature |

0°C to 45°C (32°F to 113°F) |

|

|

|

Relative humidity |

10% to 95% (noncondensing) |

|

|

|

Cleanliness |

· Dust concentration ≤ 1.8 × 107 particles/m3. · No dust on desk within three days |

|

|

|

ESD prevention |

· The equipment and floor are reliably grounded. · The equipment room is dust-proof. · The humidity and temperature are in the acceptable range. · Wear an ESD wrist strap and uniform when touching a circuit board. · Place the removed memory module, CF card, or HIM/MIM/MIC/MIC-X on an antistatic workbench, with the face upward, or put it into an antistatic bag. · Touch only the edges, instead of electronic components when observing or moving a removed memory module, CF card, or HIM/MIM/MIC/MIC-X. |

|

|

|

EMI prevention |

· Take effective measures to filter interference from the power grid. · Separate the grounding facility of the router from the grounding facility and lightning protection facility of the other electrical devices as far as possible. · Keep the router far away from radio stations, radar and high-frequency devices working in high current. · Use electromagnetic shielding when necessary. |

|

|

|

Lightning protection |

· The grounding cable of the chassis is reliably grounded. · The grounding terminal of the AC power receptacle is reliably grounded. · A port lightning arrester is installed. (Optional) · A power lightning arrester is installed. (Optional) · A signal lightning arrester is installed at the input end of an external signal cable. (Optional) |

|

|

|

Electricity safety |

· Equip an uninterrupted power supply (UPS). · In case of emergency during operation, switch off the external power switch. |

|

|

|

Workbench |

· The workbench is stable enough · Well grounding |

|

|

|

Rack-mounting requirements |

· Install the router in an open rack if possible. If you install the router in a closed cabinet, make sure the cabinet is equipped with a good ventilation system. · The rack is sturdy enough to support the weight of the router and installation accessories. · The size of the rack is appropriate for the router. · The front and rear of the rack are a minimum of 0.8 m (31.50 in) away from walls or other devices. |

|

|

|

Safety precautions |

· The router is far away from any moist area and heat source. · The emergency power switch in the equipment room is located. |

|

|

|

Tools |

· Installation accessories supplied with the router · User supplied tools |

|

|

|

Reference |

· Documents shipped with the router · Online documents |

|

|

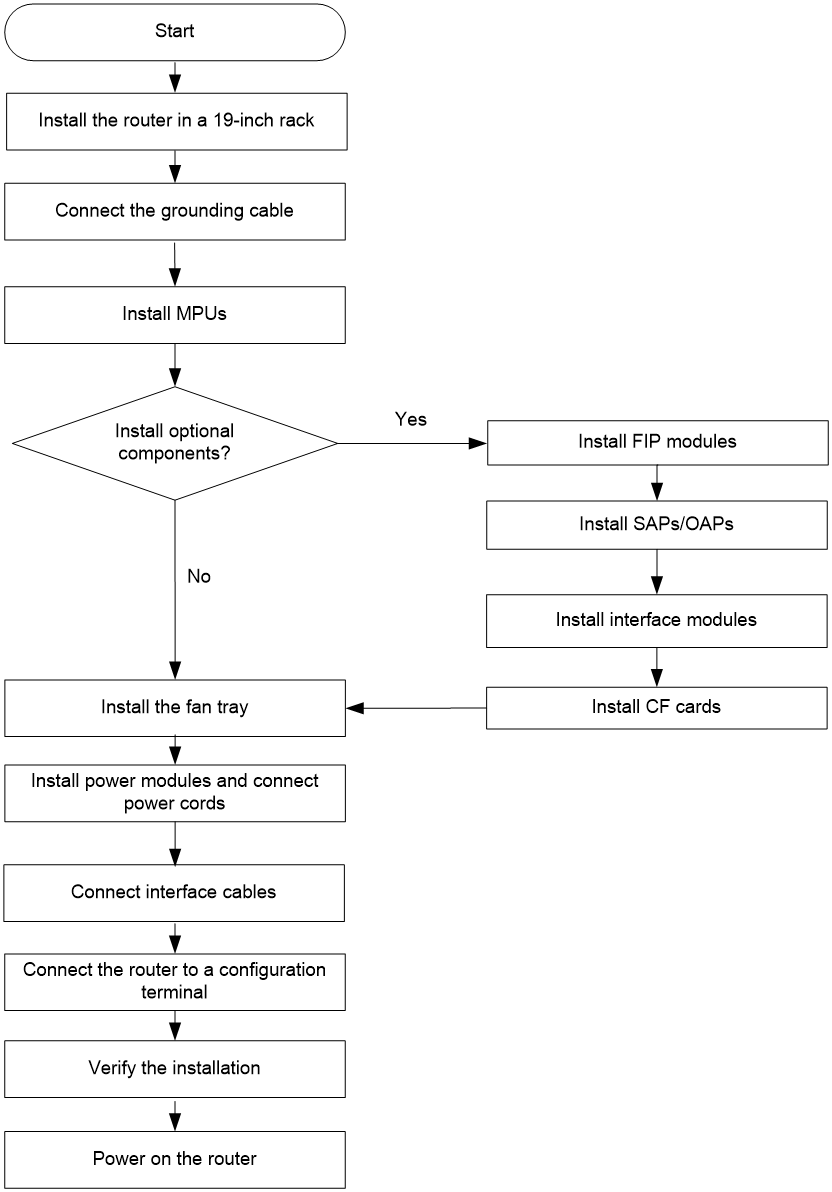

2 Installing the router

|

IMPORTANT: Keep the packages of your router and its accessories safe for future use. |

Figure2-1 Router installation flow

Check before installation

To prepare for installing the router:

· Make sure you have read "Preparing for installation" carefully and the installation site meets all the requirements.

· Prepare a 19-inch rack. For more information about how to install a rack, see the installation guide provided with the rack.

· Make sure the rack is sturdy and securely grounded.

· Make sure there is sufficient clearance around the rack for heat dissipation and installation.

· Make sure there is no debris inside or around the rack.

· Move the router to a place near the rack.

Installing the router in a 19-inch rack

You can install the router in a rack by using mounting brackets and a rack shelf or using mounting brackets and slide rails. Select an installation method as required.

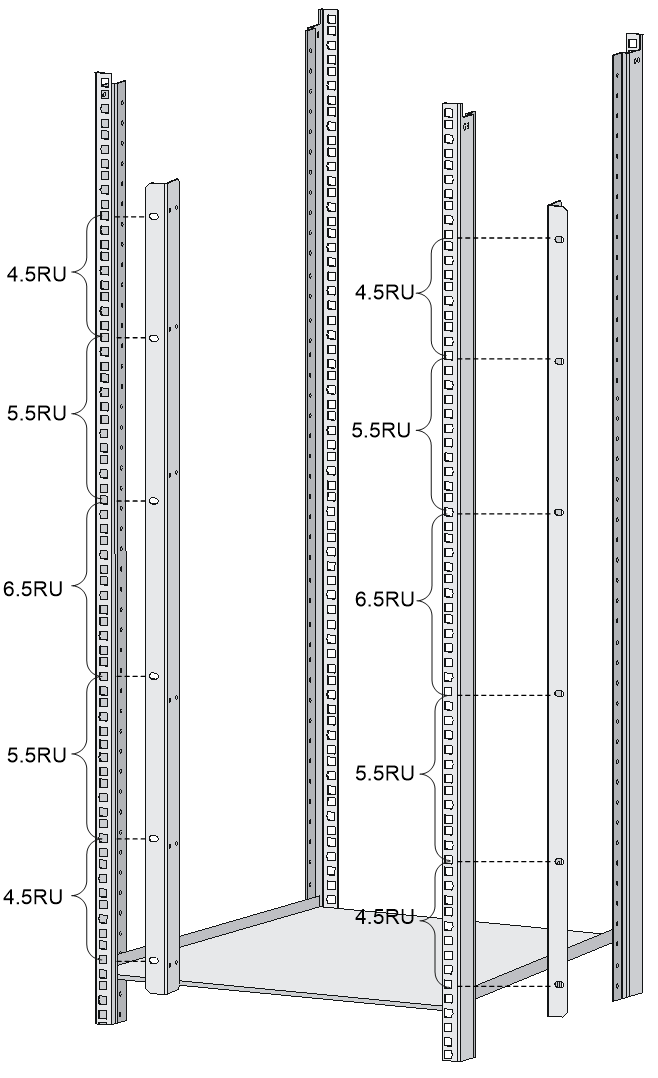

Installing the router by using mounting brackets and a rack shelf

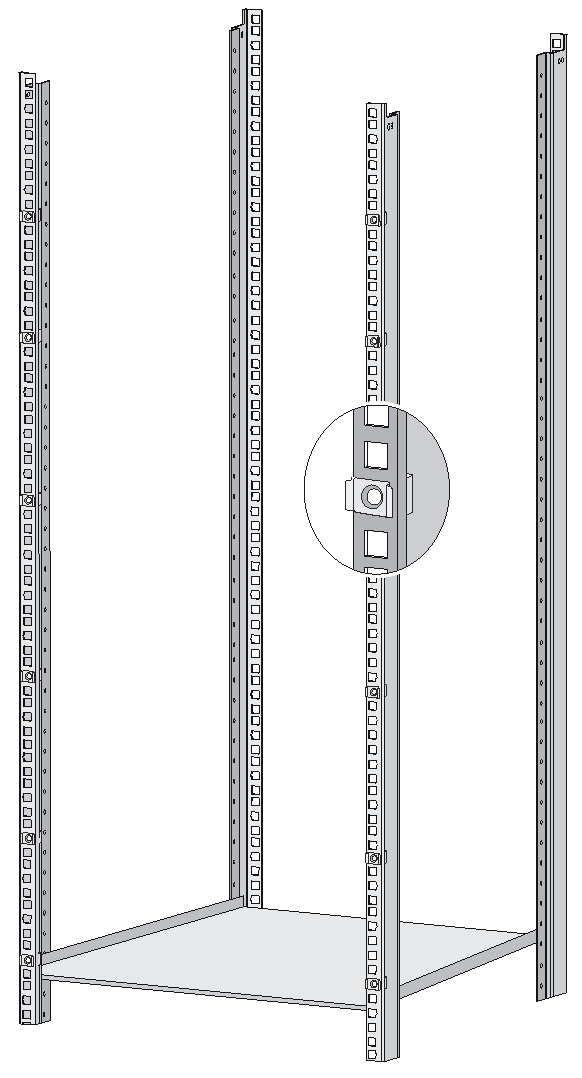

Attaching cage nuts to the rack

1. Determine where to install the router in the rack, and then install a rack shelf on the rack.

2. As shown in Figure2-2, mark the positions of cage nuts on the front rack posts by using a front mounting bracket according to the position of the rack shelf.

Figure2-2 Marking the positions of the cage nuts

3. As shown in Figure2-3, attach the cage nuts to the marked positions on the rack posts.

Figure2-3 Installing cage nuts

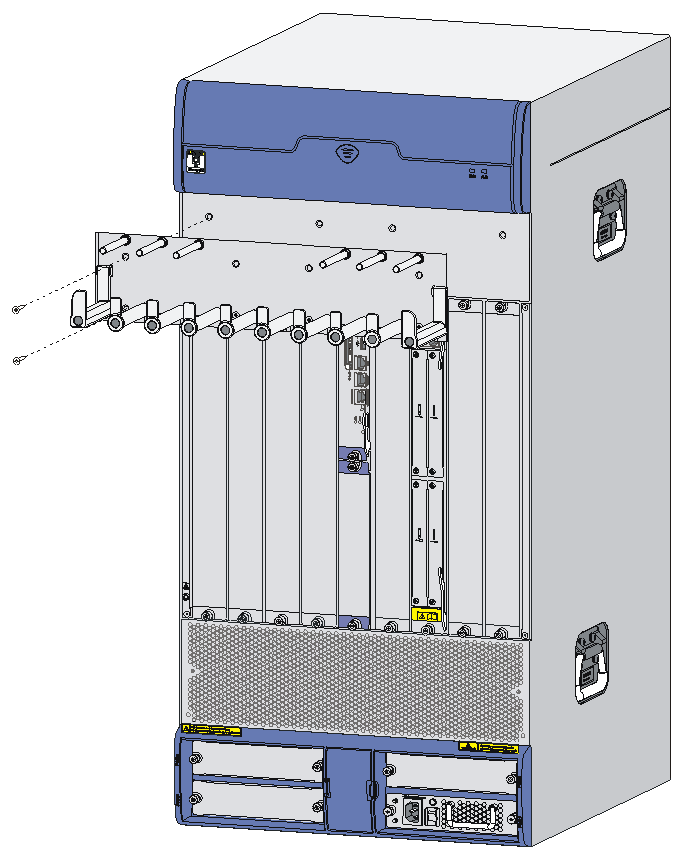

Installing the cable management brackets

As shown in Figure2-4, before attaching a mounting bracket to the router, attach the cable management bracket to the left mounting bracket with screws.

Figure2-4 Installing the cable management bracket

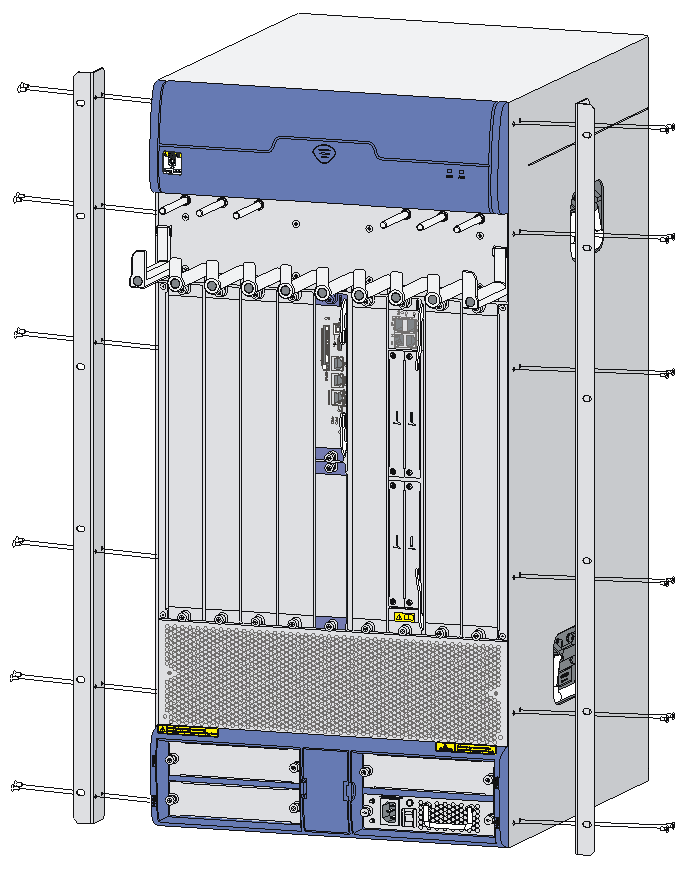

Attaching the mounting brackets to the router

Before installing the router in a rack, install the front mounting brackets to the two sides of the router.

To attach the front mounting brackets to the router, align the screw holes on the mounting brackets with the screw holes on the router chassis, and then fasten the screws.

Figure2-5 Attaching the front mounting brackets to the two sides of the router

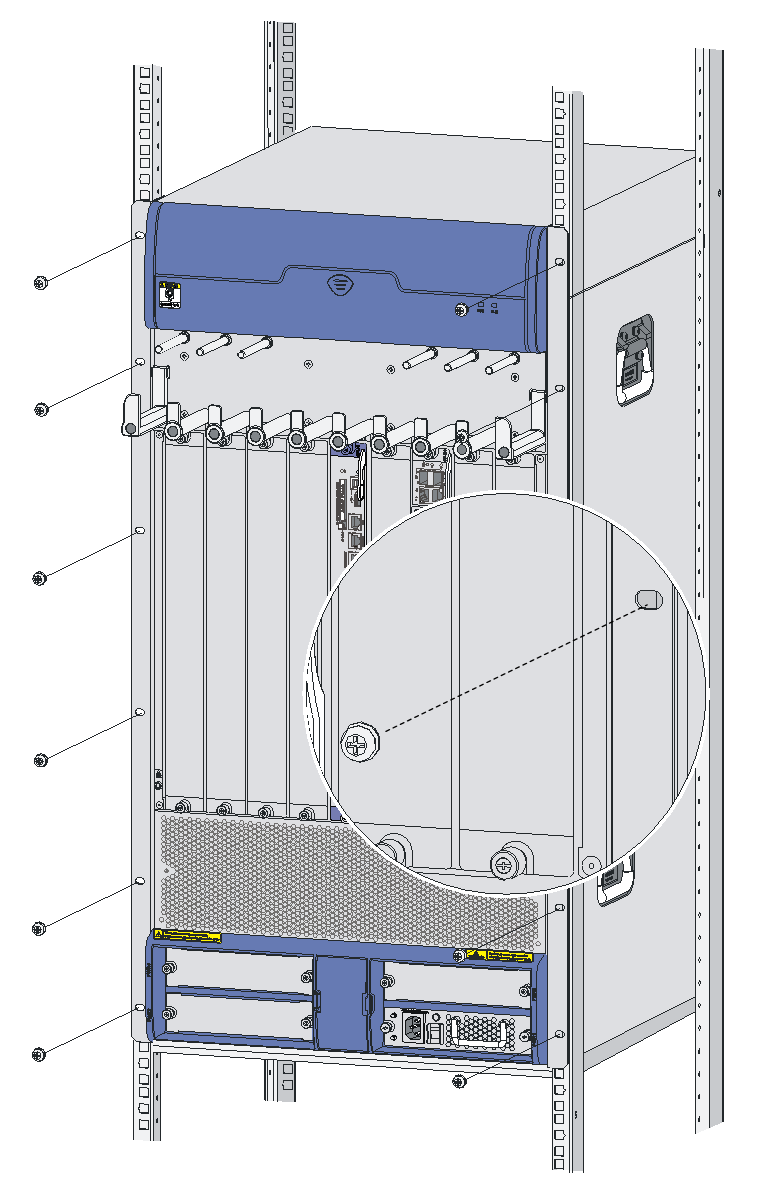

Installing the router in the rack

|

IMPORTANT: If you have ordered an air filter for the router, attach it to the router before rack-mounting the router. For the air filter installation procedure, see "Installing an air filter." |

1. Put the router on the rack shelf, and slide the router into the rack, making sure that there is enough clearance between the router and rack posts for installing the mounting brackets.

Figure2-6 Installing the router in the rack

Installing the router by using mounting brackets and slide rails

The procedure is similar for installing the router by using mounting brackets and slide rails and by using mounting brackets and a rack shelf. For more information, see "Installing the router by using mounting brackets and a rack shelf."

Before installing the router in the rack, attach slides rails to the rack. As a best practice, purchase slide rails from H3C. Table2-1 describes the slide rails available for the router. For information about installing the slide rails, see the installation guide shipped with the slide rails.

If the rack has slide rails installed, skip this step.

|

IMPORTANT: Select slide rails for the router based on the total chassis weight. |

Table2-2 Slide rails available for the router

|

Router model |

Chassis weight (fully configured) |

Available slide rails |

||||

|

Slide rail model |

Max. load-bearing capacity |

Adjustment range |

Occupied space |

Remarks |

||

|

SR6616/SR6616-DS |

102 kg (224.87 lb) |

LSXM1BSR |

450 kg (992.06 lb) |

630 to 900 mm (24.80 to 35.43 in) |

1 RU |

Select one of the slide rail models |

|

LSTM1KSGD0 |

280 kg (617.28 lb) |

300 to 500 mm (11.81 to 19.69 in) |

2 RU |

|||

|

LSTM2KSGD0 |

360 kg (793.65 lb) |

500 to 800 mm (19.69 to 31.50 in) |

2 RU |

|||

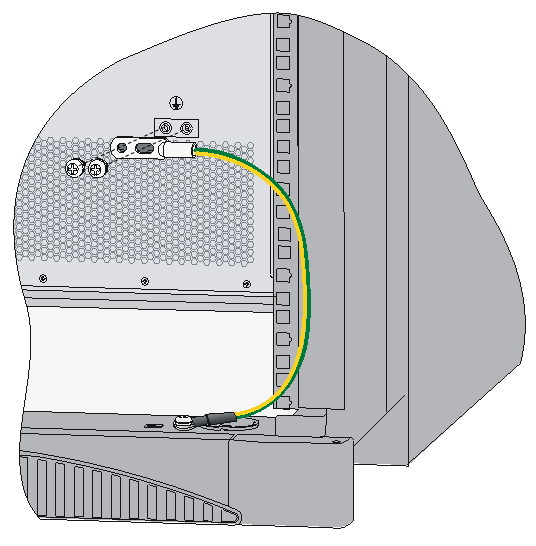

Grounding the router

|

WARNING! Correctly connecting the router grounding cable is crucial to lightning protection and EMI protection. |

To connect the grounding cable:

1. Remove the grounding screws from the grounding terminal on the rear panel of the router chassis.

2. Use the grounding screws to attach the lug of the grounding cable to the grounding terminal and fasten the screws.

3. Connect the other end of the grounding cable to the grounding strip of the rack.

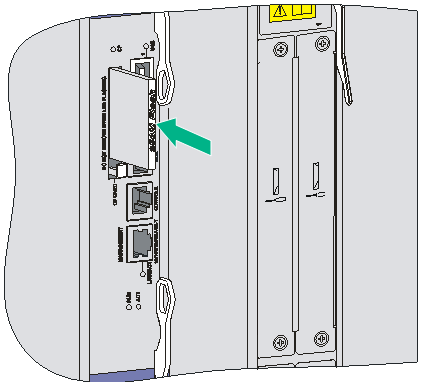

Figure2-7 Connecting the grounding cable to the grounding hole of router

|

|

NOTE: · Make sure the resistance reading between router chassis and the ground is smaller than 5 ohms. · To guarantee the grounding effect, use the grounding cable provided with the router to connect to the grounding strip in the equipment room as long as possible. |

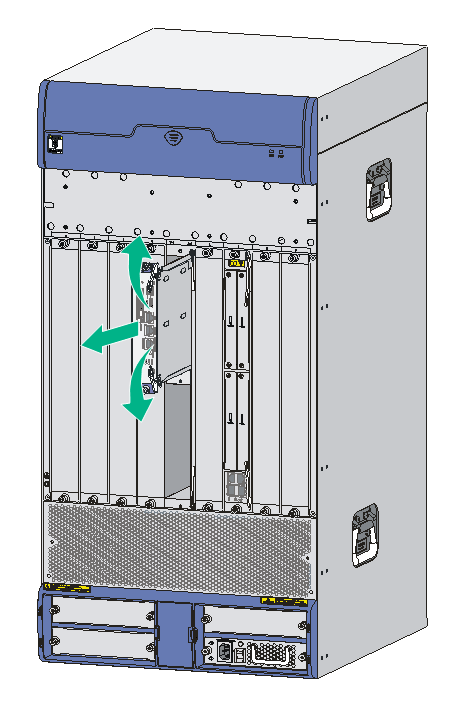

Installing an MPU

|

CAUTION: · When the router is installed with two MPUs, the standby MPU is hot swappable. When the router is installed with one MPU, the MPU is not hot swappable. · To avoid hardware damage, do not hot swap a FIP or SAP/OAP during the booting process of an MPU (with the RUN LED fast flashing). |

When two MPUs are installed on the router, the ACT LED on the active MPU is steady green. For the MPU LED descriptions, see H3C SR6616 Routers Hardware Information and Specifications.

Installing an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU

Before installing an RPE-X1, RPE-X3, RPE-X5, or RPE-X5E MPU, install a compatible carrier in the MPU slot. The RPE-X1 MPU supports the BKEB carrier, the RPE-X3 MPU supports the BKEC carrier, and the RPE-X5/RPE-X5E MPU supports the BKEE carrier. For the carrier model, see the barcode on the carrier.

The installation procedures for the RPE-X1, RPE-X3, RPE-X5, and RPE-X5E are the same. This example uses an RPE-X1.

To install an RPE-X1 MPU:

1. Locate the slot to install the RPE-X1 MPU.

The RPE-X1 MPU can be installed in slot 4 or slot 5. This procedure uses slot 4 as an example.

2. Gently push the RPE-X1 carrier (with the components facing up) into slot 4 along the slide rails until the positioning pins on the backplane are seated in the positioning holes at the bottom of the RPE-X1 carrier. Then push the ejector levers inward to lock the RPE-X1 carrier in position and fasten the captive screws on the ejector levers.

Figure2-8 Internal structure of the RPE-X1 carrier

Figure2-9 Installing the RPE-X1 carrier

3. Use even pressure to gently push the RPE-X1 into slot 4 along the slide rails, and then push the ejector levers inward to lock the RPE-X1 in position.

Figure2-10 Inserting the RPE-X1 into the slot

4. Fasten the captive screws on the RPE-X1.

5. Observe the RUN LED on the RPE-X1 to verify that the RPE-X1 is installed correctly.

After the router is powered on, the RUN LED on the RPE-X1 flashes green at 8 Hz until the application software is loaded. When the RUN LED flashes green at 1 Hz, the RPE-X1 is operating correctly.

Installing an RSE-X1 MPU

1. Locate the slot to install the RSE-X1.

You can install an RSE-X1 in slot 5 or slot 6. This procedure uses slot 5 as an example.

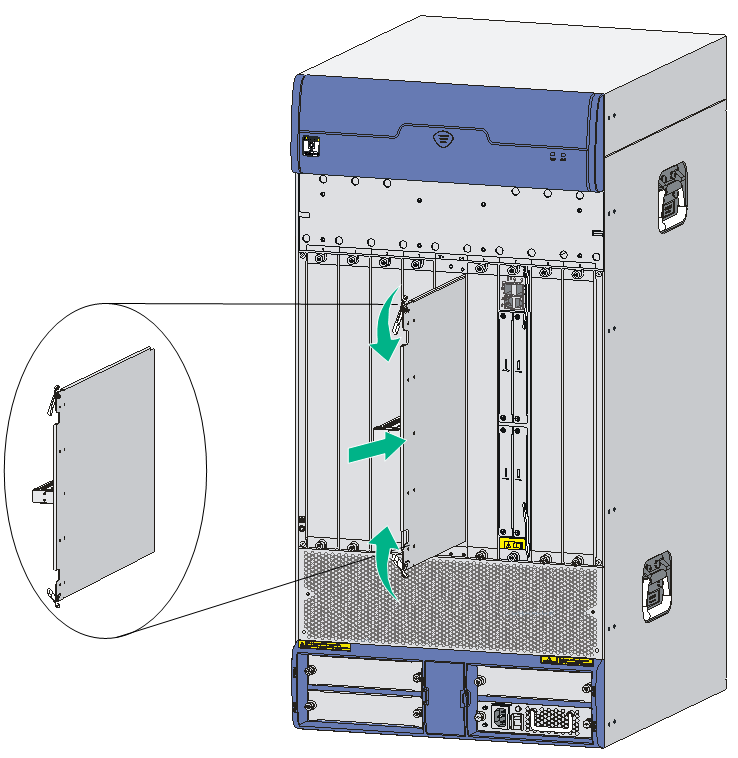

2. Loosen the captive screws on the filler panel in slot 5, and then remove the filler panel

3. Use even pressure to gently push the RSE-X1 into slot 5 along the slide rails, and then push the ejector levers inward to lock the RSE-X1 in position.

Figure2-11 Inserting the RSE-X1 into the slot

4. Fasten the captive screws on the RSE-X1.

5. Observe the RUN LED on the RSE-X1 to verify that the RSE-X1 is installed correctly.

After the router is powered on, the RUN LED on the RSE-X1 flashes green at 8 Hz until the application software is loaded. When the RUN LED flashes green at 1 Hz, the RSE-X1 is operating correctly.

Installing an MCP MPU

|

IMPORTANT: An MCP MPU supports only FIP-10 and FIP-20 modules. |

You can install an MCP in slot 5 or slot 6. The installation procedure is similar for MCPs. The following procedure installs an MCP-X1 in slot 5.

To install an MCP:

1. Loosen the captive screws on the filler panel in slot 5, and then remove the filler panel.

2. Use even pressure to gently push the MCP into slot 5 along the slide rails until positioning pins on the backplane are seated in the positioning holes, and then push the ejector levers inward to lock the MCP in position.

Figure2-12 Inserting the MCP into the slot

3. Fasten the captive screws on the MCP.

4. Observe the RUN LEDs on the MCP to verify that the MCP is installed correctly.

After the router is powered on, the RUN LED on the MCP flashes green at 8 Hz until the application software is loaded. When the RUN LED flashes green at 1 Hz, the MCP is operating correctly.

Installing an SSD drive

Only the RPE-X5E, FIP-260, FIP-380, and SAP-XP4GE32 modules support mSATA SSD drives (the router does not support SSC-enabled SSD drives).

No SSD drive or screws are provided with the router. Prepare them yourself as required. For correct operation of the device, use H3C SSD drives.

To install an SSD drive:

1. Locate the SSD drive slot on the service module.

Figure2-13 Service module structure (FIP-260)

|

(1) Front panel |

(2) SSD drive slot |

2. Align the golden plating on the SSD drive with the mSATA connector in the slot.

3. Slightly press the SSD drive until it is level with the surface of the connector.

4. Use a Phillips screwdriver to screw the SSD drive into place.

Figure2-14 Installing an SSD drive

Installing a FIP module and an air deflector

Installing a FIP module

|

IMPORTANT: FIP-10 and FIP-20 can operate correctly only on a router installed with an MCP. |

The router supports hot swapping of FIP modules.

The installation procedure is similar for FIPs. The following procedure installs a FIP-210.

To install a FIP module:

1. Locate the slot to install the FIP module.

2. Remove the captive screws on the filler panel, and then remove the filler panel.

3. Use even pressure to gently push the FIP module into the slot along the slide rails until positioning pins are seated in the positioning holes in the backplane, and then push the ejector levers inward to lock the FIP module in position.

If you encounter a resistance when pushing a FIP module into slot, remove the filler panels from the left and right slots and then install the FIP module. After the FIP module is installed, reinstall the removed filler panels to prevent dust from entering the chassis.

Figure2-15 Inserting a FIP module

4. Fasten the captive screws on the FIP module.

5. Observe the RUN LED on the FIP to verify that the FIP module is installed correctly.

After the router is powered on, the RUN LED on the FIP flashes green once and then fast flashes (at 8 Hz) until the application software is loaded. When the RUN LED flashes green at 1 Hz, the FIP is operating correctly.

For the FIP LED descriptions, see H3C SR6616 Routers Hardware Information and Specifications

(Optional) Installing an air deflector

For a FIP-660, if a service module slot adjacent to the FIP-660 is empty, install an air deflector over the slot.

To install an air deflector:

1. Locate the service module slot to install the air deflector.

2. Loosen the captive screws on the filler panel, and then remove the filler panel.

3. Gently push the air deflector into the service slot along the slide rails until it snaps into the place.

4. Fasten the captive screws on the air deflector.

Figure2-16 Installing an air deflector

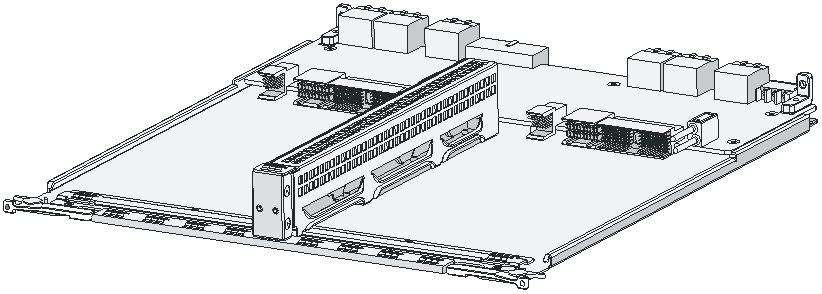

Installing a SAP/OAP/switching fabric module

The router supports hot swapping of SAPs, OAPs, and switching fabric modules.

The installation procedure is similar for SAPs, OAPs, and switching fabric modules. The following procedure installs a SAP module.

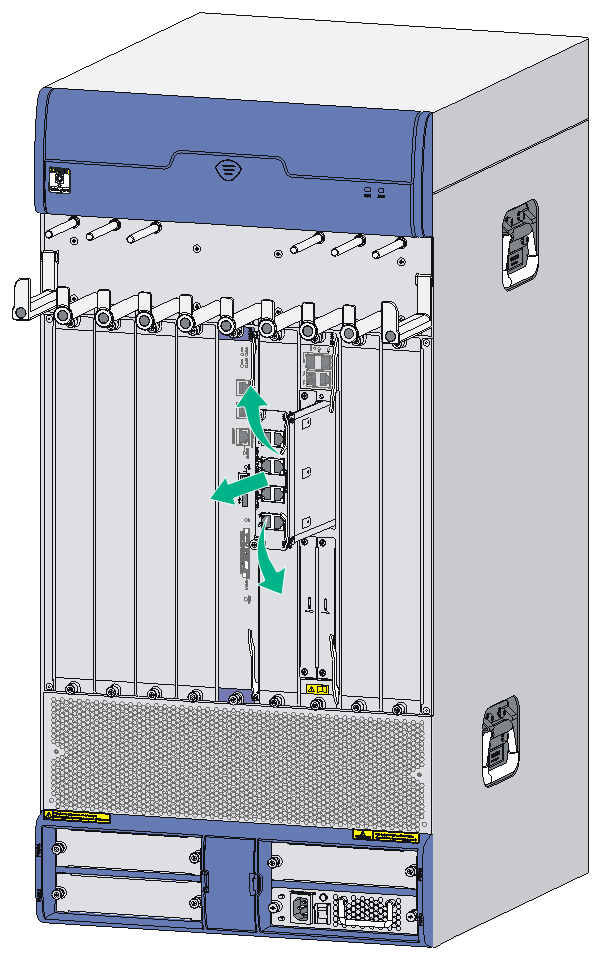

To install a SAP module:

1. Locate the slot to install the SAP module.

2. Loosen the captive screws on the filler panel, and then remove the filler panel.

3. Use even pressure to gently push the SAP module into the slot along the slide rails until the positioning pins on the backplane are seated in the positioning holes, and then push the ejector levers inward to lock the SAP module in position.

Figure2-17 Inserting a SAP module

4. Fasten the captive screws on the SAP module.

5. Observe the RUN LED on the SAP module to verify that the SAP module is installed correctly.

After the router is powered on, the RUN LED on the SAP flashes green once and then fast flashes (at 8 Hz) until the application software is loaded. When the RUN LED flashes green at 1 Hz, the SAP is operating correctly.

Installing a HIM/MIM/MIC/MIC-X interface module

|

CAUTION: · MIM interface modules are not hot swappable. MIC interface modules are hot swappable. · All MIC-X interface modules except the MIC-X-CNDE-SJK are hot swappable. To remove a MIC-X-CNDE-SJK interface module when the router is operating, press the REMOVE button on the interface module until its RUN LED turns off. · HIM interface modules can be hot swapped. To remove a HIM interface module when the router is operating, first execute the remove command for the interface module. · To avoid hardware damage, when the RUN LED on a FIP module is fast flashing green, do not install or remove a HIM/MIM/MIC/MIC-X module on it. |

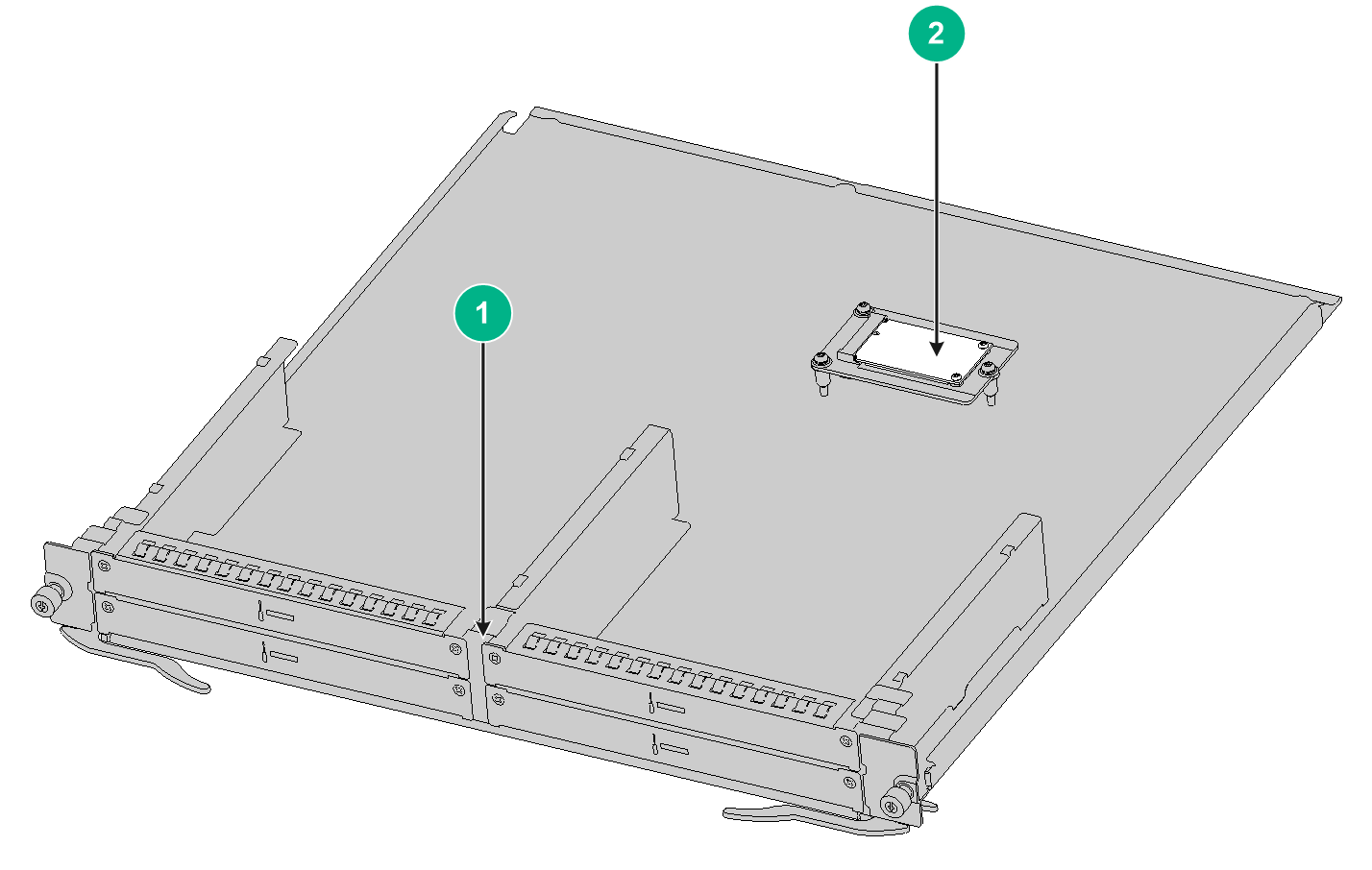

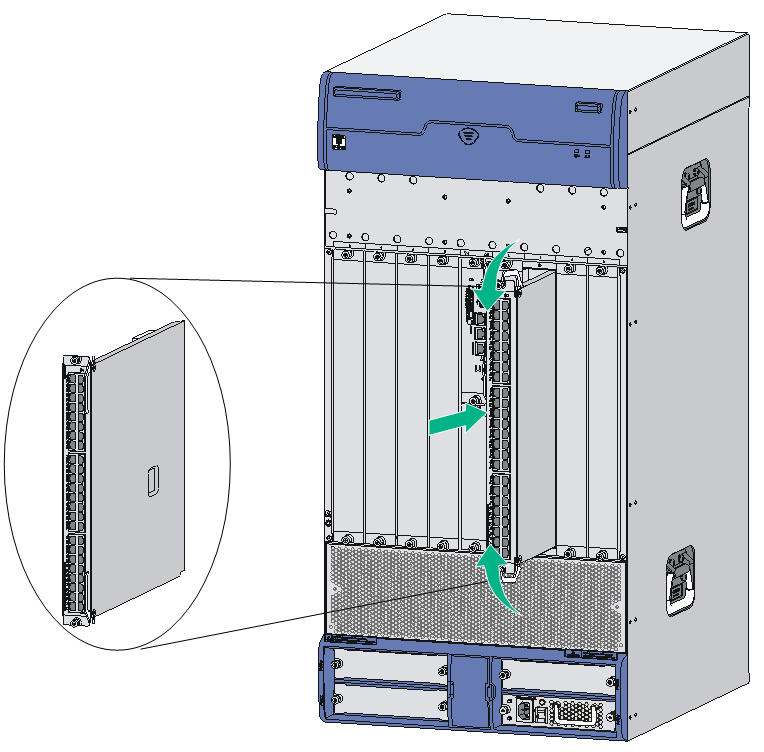

Assembling a MIC-X adapter module and MIC interface module into a MIC-X interface module

|

IMPORTANT: A MIC-X-ET16-compatible FIP module supports only one MIC-X-ET16 assembled by a MIC-X adapter module and a MIC-ET16L interface module. |

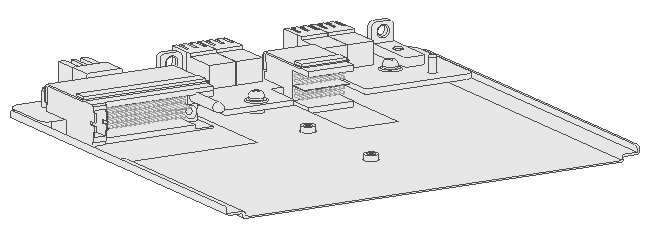

MIC-X adapter module components

Figure2-18 Screw

Figure2-19 Carrier

Figure2-20 Front panel

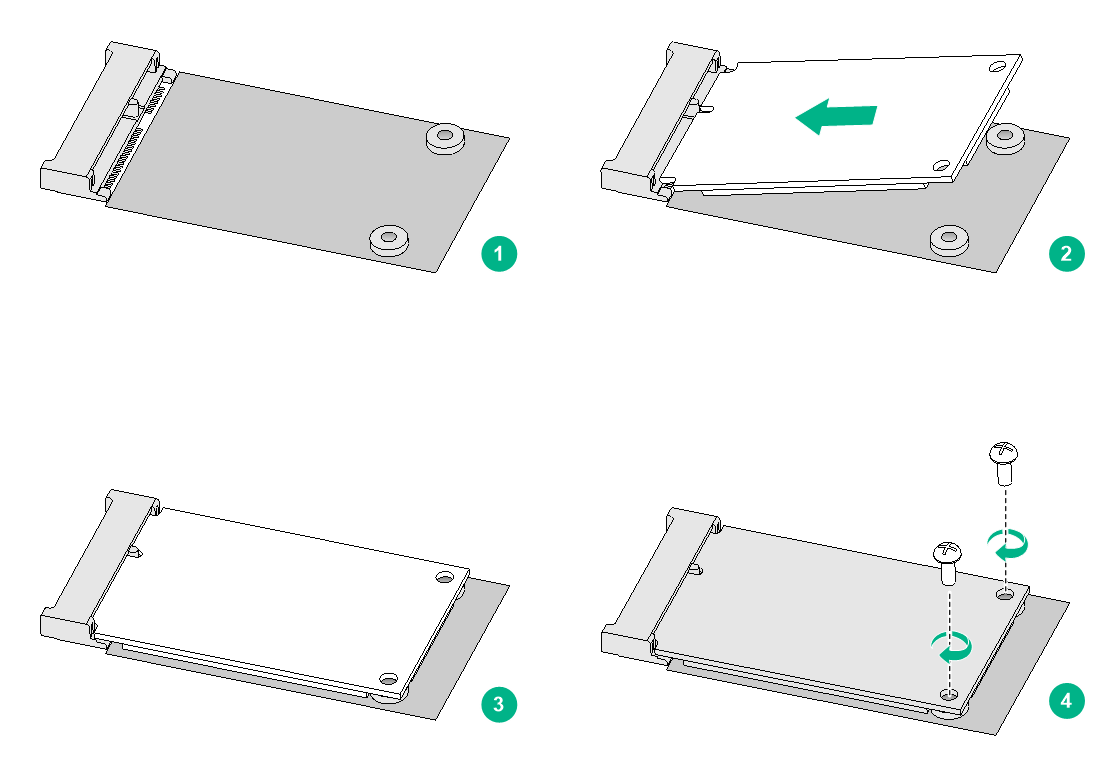

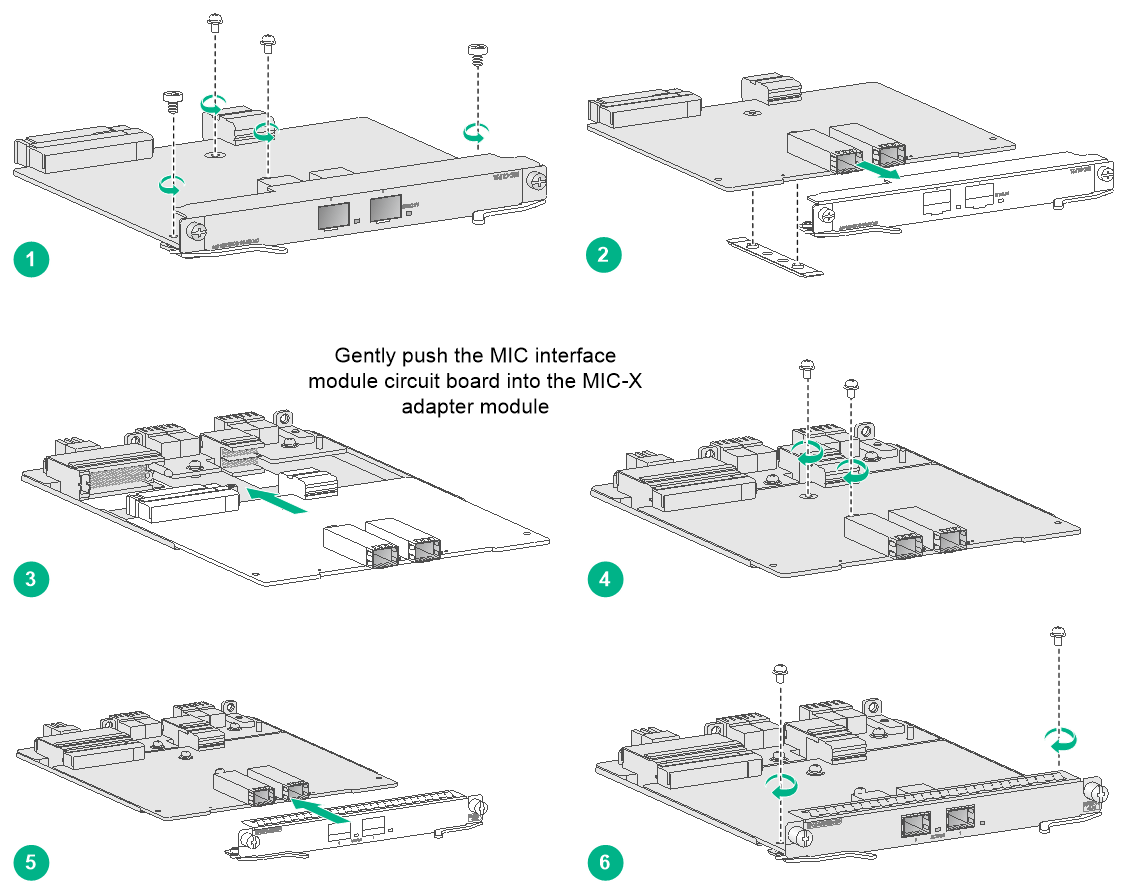

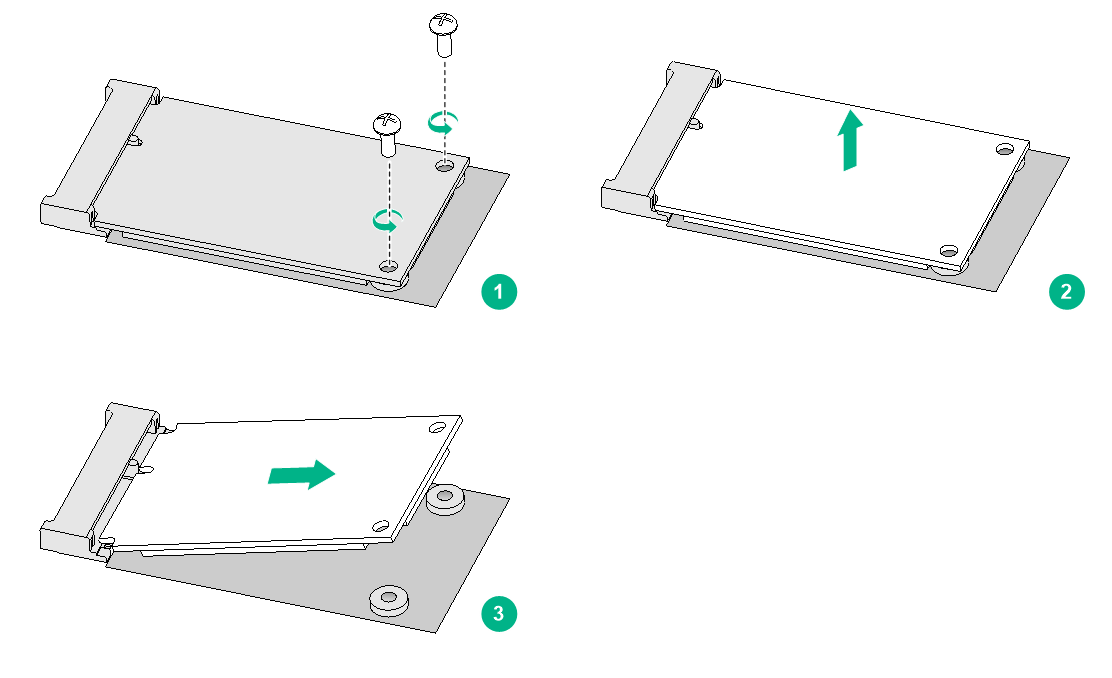

Assembling a MIC-X adapter module and MIC interface module into a MIC-X interface module

1. Use a screwdriver to remove the four screws from the MIC interface module circuit board so that the front panel and the gasket are disengaged from the circuit board.

2. Align the MIC interface module circuit board with the guide rails on the MIC-X adapter module carrier. Gently push the circuit board into the carrier along the guide rails until the circuit board makes close contact with the connectors on the MIC-X adapter module carrier.

3. Install M3 screws provided with the MIC-X adapter module carrier into the two screw holes at the center of MIC interface module circuit board and fasten the screws.

4. Select the front panel matching the MIC interface module, align the front panel with the ports on the circuit board, and use M3 screws to attach the front panel to the circuit board.

The MIC-CLP2L, MIC-CLP4L, MIC-SP4L, MIC-SP8L, MIC-ET16L interface modules can be assembled into corresponding MIC-X modules by using MIC-X adapter modules.

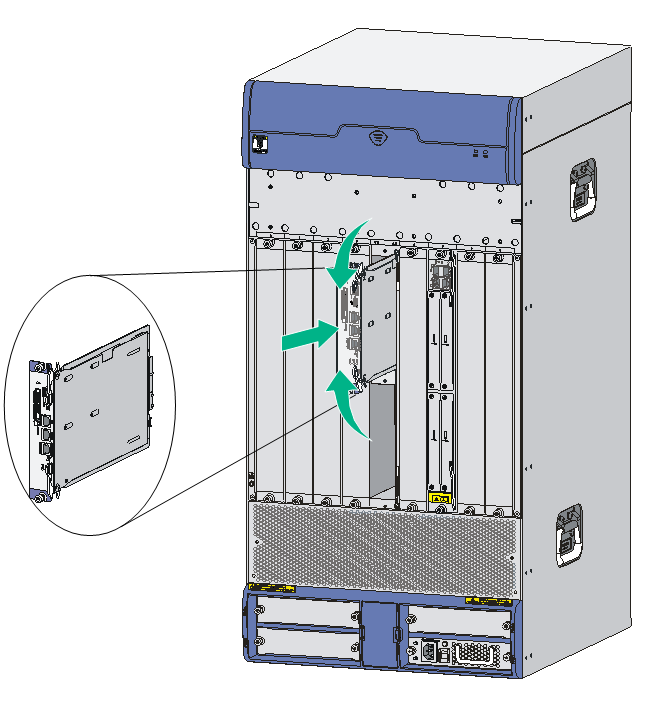

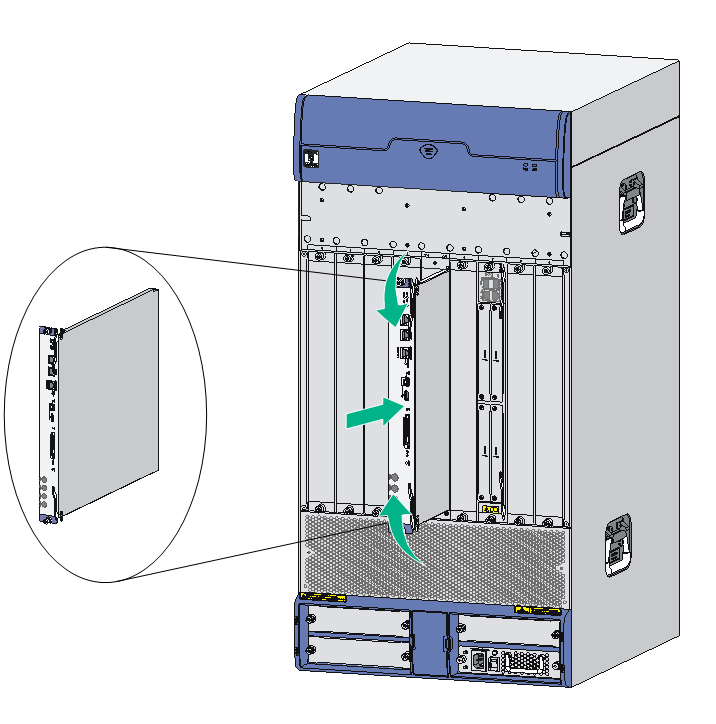

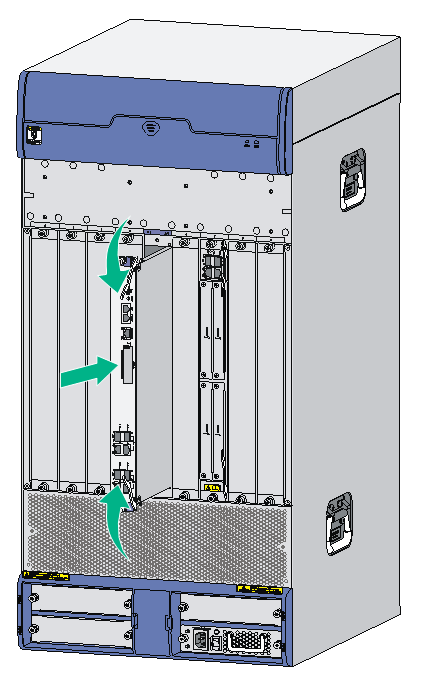

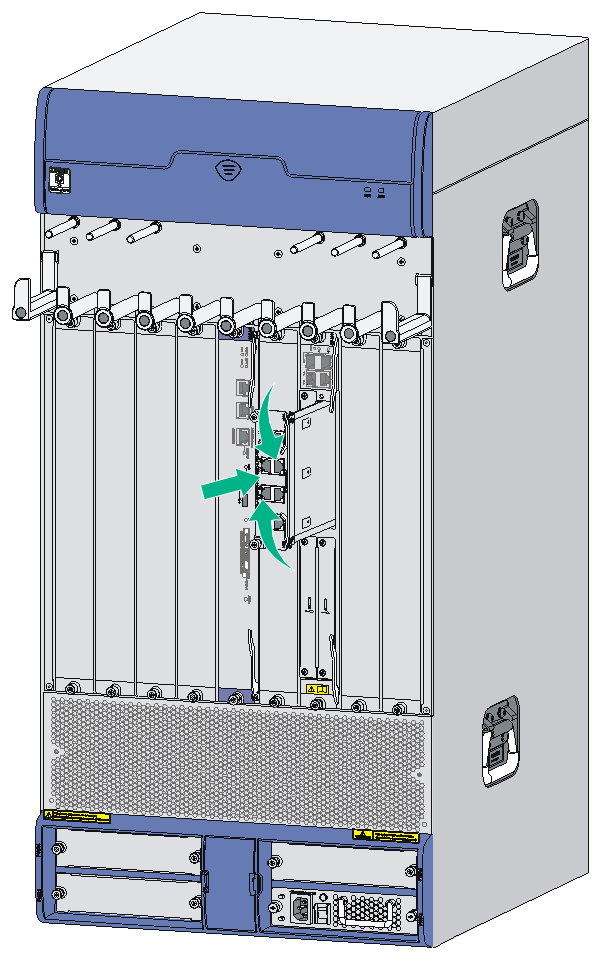

Installing an interface module

The installation procedure is the same for HIM, MIM, MIC, and MIC-X interface modules.

To install a HIM/MIM/MIC/MIC-X interface module:

1. Locate the slot to install the HIM/MIM/MIC/MIC-X on the FIP module.

2. Loosen the captive screws on the filler panel, and then remove the filler panel.

Keep the filler panel safe for future use.

3. Use even pressure to push the HIM/MIM/MIC/MIC-X slowly along the slide rails into the slot, and then close the ejector levers inward.

Install a HIM/MIM/MIC-X with its PCB components facing right and install a MIC with its PCB components facing left.

Figure2-22 Installing a HIM/MIM/MIC/MIC-X

4. Fasten the captive screws on the HIM/MIM/MIC/MIC-X.

5. Observe the LED for the slot on the router front panel to verify that the HIM/MIM/MIC/MIC-X is installed correctly.

If the LED is on after the HIM/MIM/MIC/MIC-X initialization completes, the HIM/MIM/MIC/MIC-X has been installed correctly and is operating correctly. If the LED is Off, the HIM/MIM/MIC/MIC-X has failed the POST.

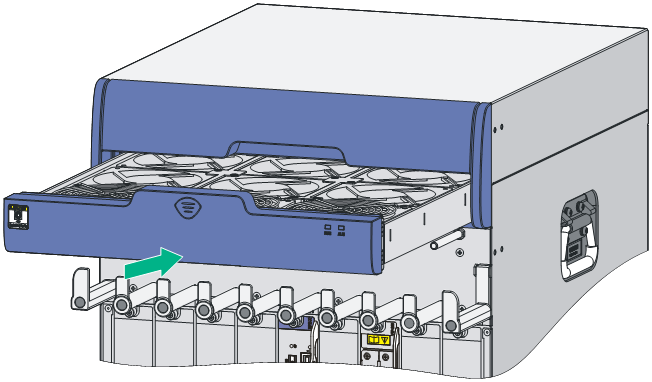

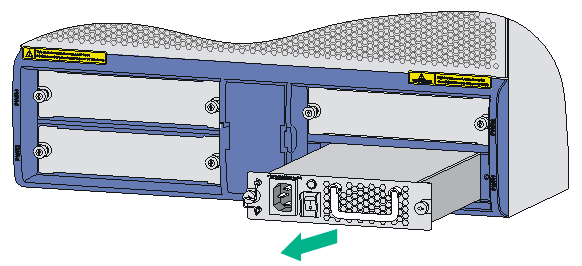

Installing a fan tray

The router supports hot swapping of fan trays. The fan trays can automatically adjust the fan speed.

To install a fan tray:

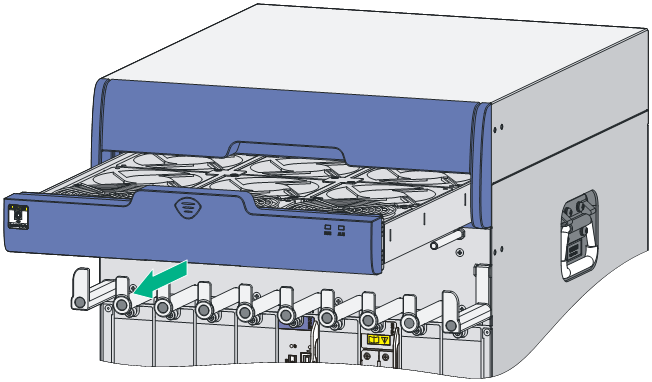

1. Orient the fan tray to make sure the warning sign on the front panel is on the left.

2. Pressing the release button on the fan tray with your thumb, and supporting the fan tray bottom with the other hand, gently push the fan tray along the slide rails into the slot until the fan tray keeps in close contact with the backplane of the router. (see Figure2-23.)

Figure2-23 Pushing the fan tray into the slot

3. Power on the router and check the status LED on the front panel.

On means the fan tray is operating correctly. Off means the fan tray has failed the POST. For the LED description of the fan tray, see H3C SR6616 Routers Hardware Information and Specifications.

Installing a CF card

To install a CF card on an MCP, remove the CF card cover first.

1. Push the CF card eject button all the way into the slot, and make sure the button does not project from the panel.

2. Insert the CF card into the slot following the direction shown in Figure2-24, and make sure it does not project from the slot.

Figure2-24 Inserting the CF card into the slot

|

|

NOTE: If the boot file of the router is stored in the CF card, before booting the router, make sure the CF card has been correctly installed. Otherwise, the router cannot be booted. |

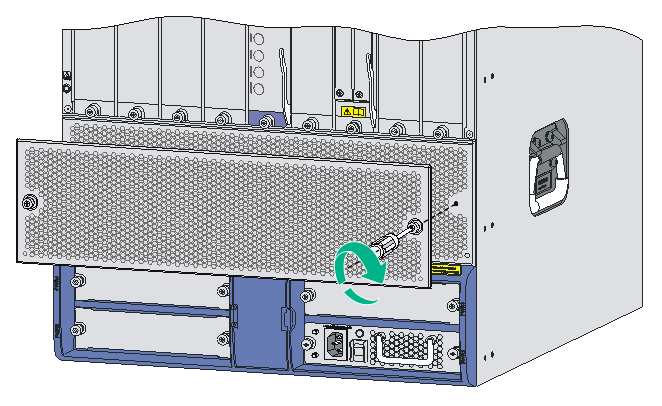

Installing a power supply

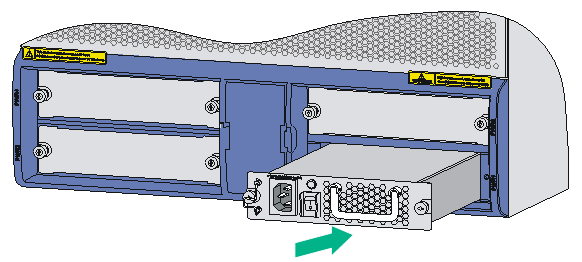

The procedures for installing an AC power supply and DC power supply are the same. The following uses a PSR650-A AC power supply as an example.

1. Locate the slot to install the power supply. Use even pressure to gently push the power supply slowly along the slide rails into the slot.

Figure2-25 Inserting the power supply into the slot

2. Fasten the captive screws on the power supply.

3. After connecting the power cord, power on the power supply. If the power supply LED is green, the power supply operates correctly. If the LED is red, the power supply has failed.

For more information about the power supply LEDs, see H3C SR6616 Routers Hardware Information and Specifications.

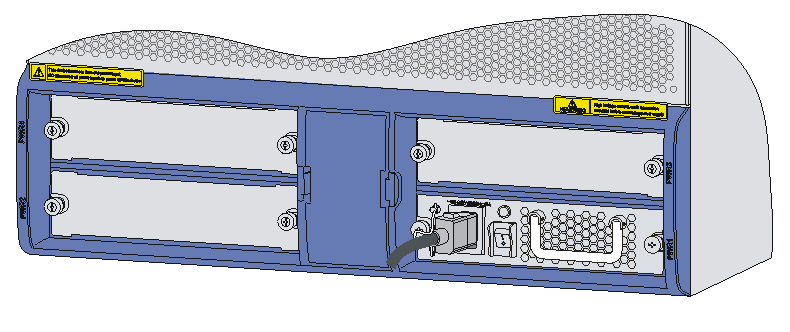

Connecting a power cord

Connecting an AC power cord

1. Make sure the router is reliably grounded, and the power switch on the router is in the OFF position.

2. Connect one end of the AC power cord to the AC receptacle on the router, and the other end to the AC power source.

3. Attach the power cord to the power supply handle by using a cable tie.

Figure2-26 Connecting an AC power cord to the router

Connecting a DC power cord

Connecting the power cord for the PSR650-D

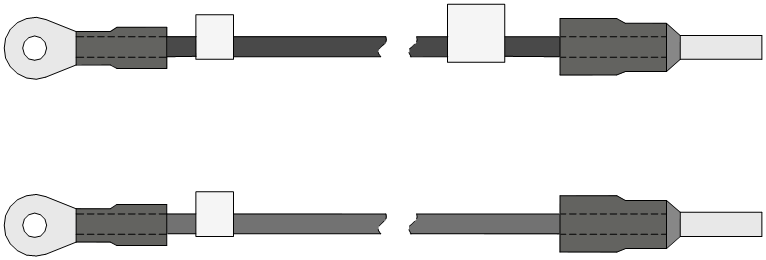

Figure2-27 DC power cord

Connecting a DC power cord

|

WARNING! Identify the label on the DC power cord when connecting a DC power cord to avoid connection mistakes. |

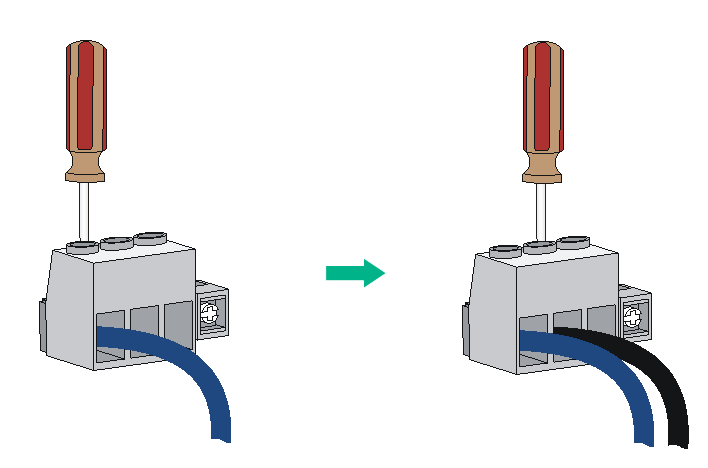

To connect a DC power cord:

1. Switch off the DC power supply.

2. Remove the protection cover of the DC power supply.

3. Remove the screws from the terminals on the power supply.

4. Connect the end marked with "–" of the supplied blue DC power cord to the negative terminal (–) on the power supply and fasten the screw.

5. Connect the end marked with "+" of the supplied black DC power cord to the positive terminal (+) on the power supply and fasten the screw.

6. Connect the other end of the DC power cord to the DC power source.

7. Install the protection cover of the DC power supply.

Figure2-28 Connecting the DC power cord

Connecting the power cord for the PSR1200-D

Figure2-29 DC power cord

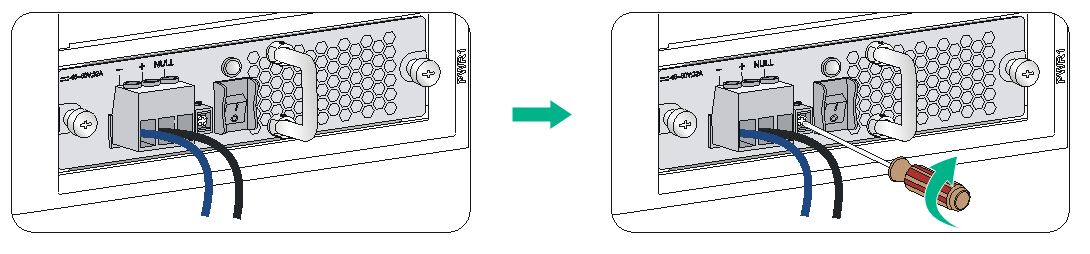

To connect the DC power cord:

1. Loosen the captive screws on the power supply to remove the power supply connector.

2. Connect the end marked with "– "to the negative terminal (–) on the power supply and fasten the screw.

3. Connect the end marked with "+"to the positive terminal (+) on the power supply and fasten the screw.

Figure2-30 Attaching the power cords to the power supply connector

4. Insert the power supply connector in right direction into the power supply, and fasten the captive screws.

Figure2-31 Installing the power supply connector to the power supply

5. Connect the other ends of the power cords to the DC power source.

3 Installing optional components

Optional components are not provided with the router. Purchase them as needed.

Installing an air filter

To install an air filter, align the positioning pins on the air filter with the screw holes near the air intake vents, and fasten the fastening screws on the air filter.

Figure3-1 Installing the air filter slide rails

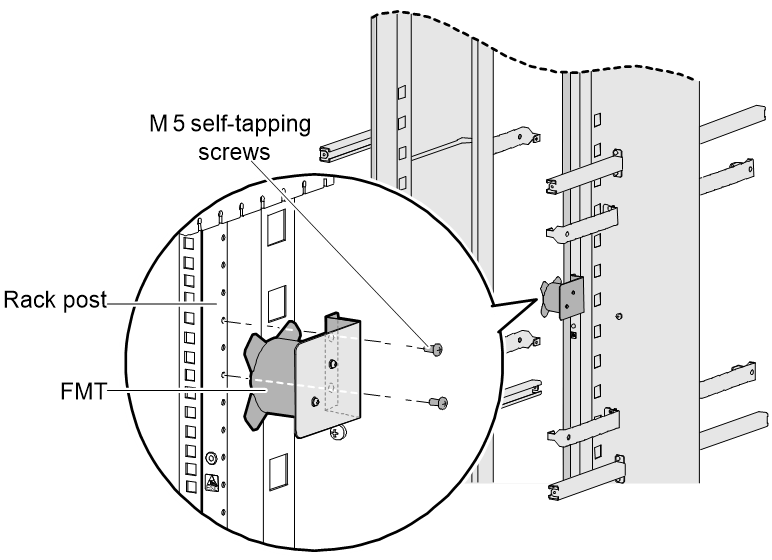

Installing a fiber management tray

Preparations

Confirm the following prerequisites:

· The rack is fixed.

· The router is installed.

The installation involves the following materials:

· Fiber management tray (FMT)

· M5×10 self-tapping screws (two screws for one FMT)

Installation procedure

To install an FMT:

1. Align the FMT and the installation holes on the rack post.

2. Use two M5×10 self-tapping screws to secure each FMT into place.

Installing a lightning protector for a network port

|

IMPORTANT: · Lightning protectors are applicable to only 10/100 Mbps copper Ethernet ports. · Read the instructions for the lightning protector carefully before you install it. · The router does not come with any lightning protector. |

If part of the network cable of a copper Ethernet port must be routed outdoors, connect a lightning protector to the cable before you plug the cable into the port. The router provides this type of lightning protector: single port, residual pulse energy (8/20μs test pulse) 5 KA, output voltage (10/700μs waveform): core-core ≤ 40 V, core-ground ≤ 600 V.

Installation procedure

1. Use a double-faced adhesive tape to stick the lightning protector onto the router chassis, and make sure it is as close to the grounding screw of the router as possible.

2. Measure the distance between the protector and the grounding screw of the router, cut the ground wire of the protector as appropriate, and securely tighten the ground wire to the grounding screw of the router.

3. Use the multimeter to measure whether the ground wire of the protector contacts well with the grounding screw of chassis.

4. Insert the outdoor network cable into the protector's IN end, and the cable connected to the router into the OUT end, and look at the indicators on the lightning protector to verify that the connection is correct.

5. Use nylon ties to bundle the cables neatly.

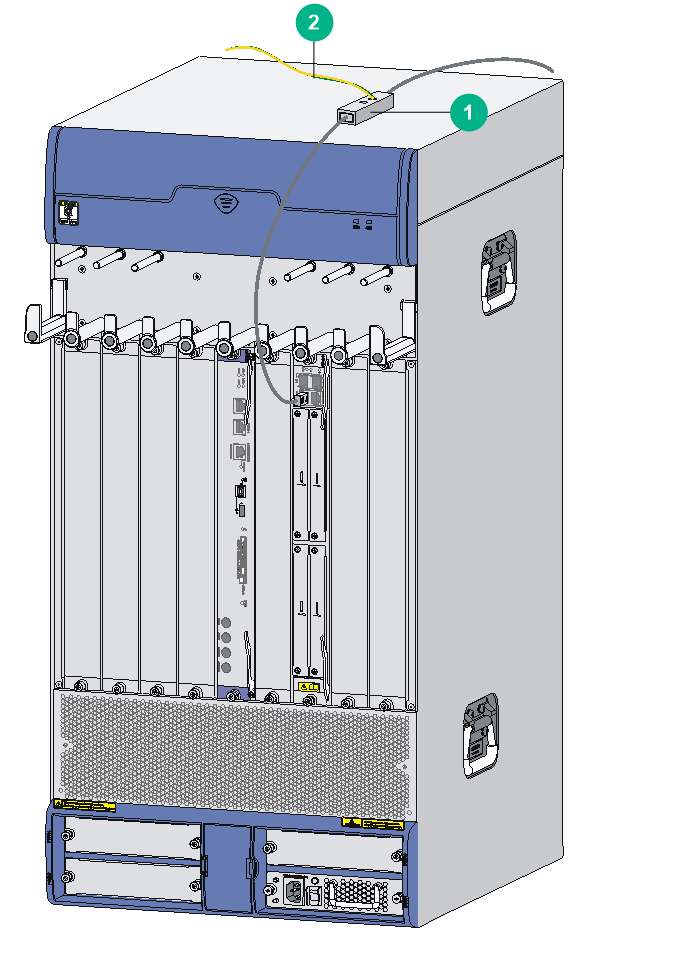

Figure3-3 Installing a lightning protector for a network port

|

(1) Lightning protector |

(2) Grounding cable |

Installation precautions

The performance of the port lightning protector might be affected in the following cases:

· The port lightning protector is installed in reverse direction. Connect the IN end to the outdoor network cable and the OUT end to the network port on the router.

· The port lightning protector is not reliably grounded. After the connection, use the multimeter to confirm that the ground wire for the protector is as short as possible to ensure its good contact with the grounding screw of the router.

· The installed port lighting protectors are not sufficient. If the router has more than one network port connected with other devices through cables outdoor, install a lightning protector for each network port.

Connecting the AC power supply to a power strip with lightning protection

|

CAUTION: Make sure the PE terminal of the power socket has been securely grounded. |

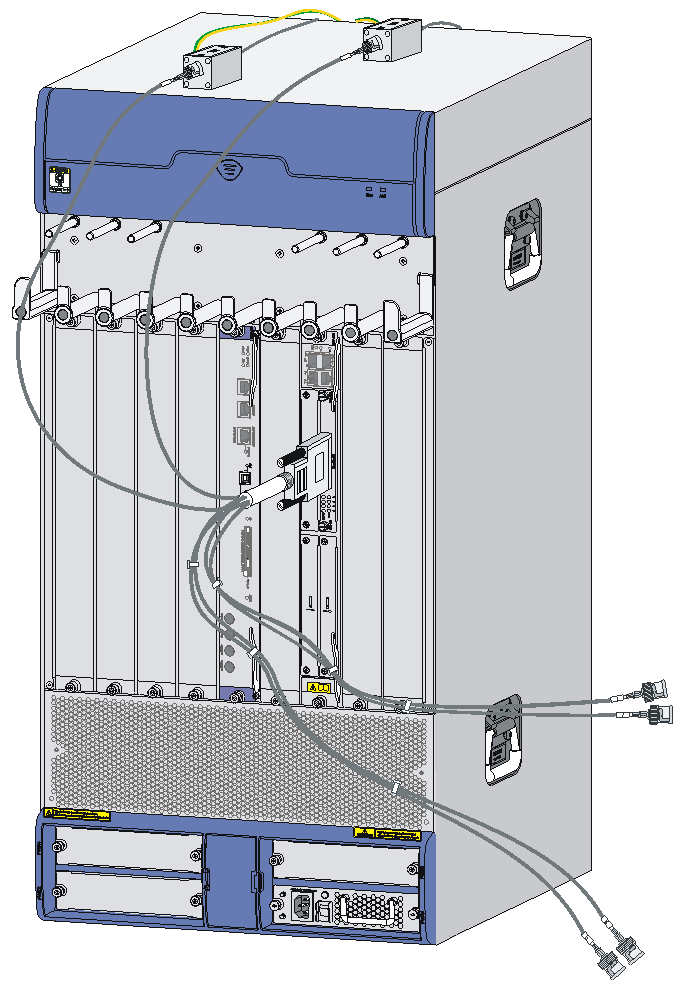

If part of the AC power line is routed outdoors, use a power strip with lightning protection to connect the AC power cord of the router to the AC power line to protect the router from being damaged by lightning strikes.

You can attach the power strip to the rack, workbench, or wall of equipment room.

After you connect the AC power cord from the router to a socket on the power strip, verify that the green RUN LED on the strip is on and the red LED is off.

If the red LED is on, use a multimeter to check the polarity of the wires in the power socket for wrong connections. If the zero wire (left) and the live wire (right) are correctly connected, check for missing grounding connection.

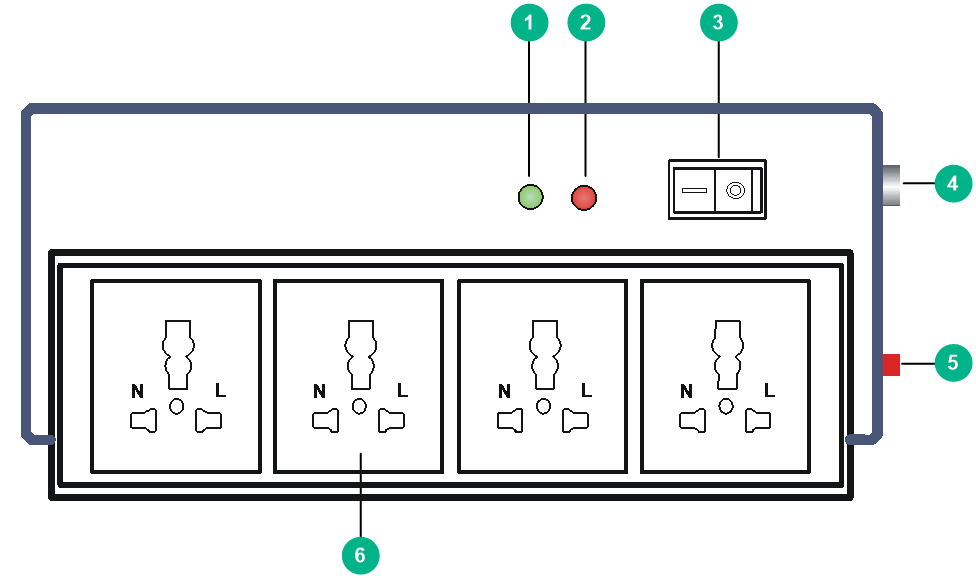

Figure3-4 Power strip with lightning protection

|

(1) Working LED (green) |

On means the circuit is operating correctly; off means the circuit is damaged. |

|

(2) Grounding/pole detection LED (red) |

On indicates a wrong wire connection (the wire is not grounded or the live line and null line are reversely connected), and you need to check the power supply line. |

|

(3) Power switch |

|

|

(4) IEC standard socket |

It is used to connect to the power supply in the equipment room through a power cord. |

|

(5) Overload automatic protector |

The protector automatically opens the electric circuit when the current exceeds the threshold and closes the electric circuit when the current drops below the threshold. |

|

(6) Multifunctional socket |

It is used to connect the power supply of the router. |

Installing a surge protector

|

CAUTION: Ground the surge protector as near as possible. The grounding resistance must be less than 4 ohms. The grounding resistance must be less than 1 ohm if there are special grounding requirements. |

Generally, you need to connect a surge protector before connecting a signal cable to the router. This can protect electronic devices against surge over-voltage resulting from lightning strokes and other interferences, and minimize impact on the router.

The surge protector is serially connected to a signal cable, so the surge protector must satisfy the requirements of network performance indexes such as data transmission bandwidth, as well as the lightning protection performance requirement. Before installing a surge protector, consider such performance indexes of the surge protector as lightning protection, bandwidth, transmission loss, and port type.

The router supports the following types of surge protectors:

· Surge protector—Maximum discharge current 2.5KA/protection voltage 25V--SMB-75J/ SMB-75J-1W-10Mbps

· Surge protector—Maximum discharge current 2.5KA/protection voltage 25V-BNC-75K/ BNC-75K-10Mbps

· Surge protector (U port)—Maximum discharge current 3KA/common-mode 400V/differential mode 170V-RJ11

To install a surge protector:

1. Use a double-faced adhesive tape to stick the surge protector onto the router chassis, and make sure it is as close to the grounding screw of the router as possible.

2. Measure the distance between the protector and the grounding screw of the router, cut the ground wire of the protector as appropriate, and securely tighten the ground wire to the grounding screw of the router.

3. Use the multimeter to measure whether the ground wire of the protector contacts well with the grounding screw of chassis.

4. Insert the outdoor network cable into the protector's IN end, and the cable connected to the router into the OUT end, and look at the indicators on the surge protector to verify that the connection is correct.

5. Use nylon ties to bundle the cables neatly.

|

|

NOTE: Read the instructions carefully before installing the surge protector. |

Figure3-5 Installing a surge protector

Precautions

The performance of the surge protector might be affected in the following cases:

· The surge protector is installed in reverse direction. Connect the IN end to the outdoor network cable and the OUT end to the network port on the router.

· The surge protector is not reliably grounded. After the connection, use the multimeter to confirm that the ground wire for the protector is as short as possible to ensure its good contact with the grounding screw of the router.

· The installed surge protectors are not sufficient. If the router has more than one cable connected with other devices through cables outdoor, install a surge protector for each cable.

4 Connecting interface cables

Connecting the AUX cable

Overview

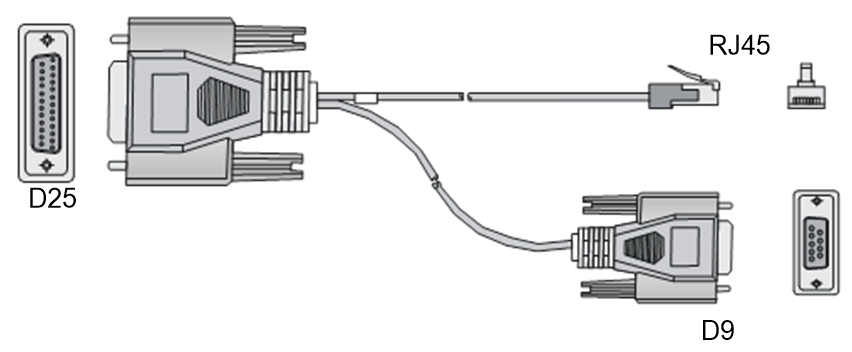

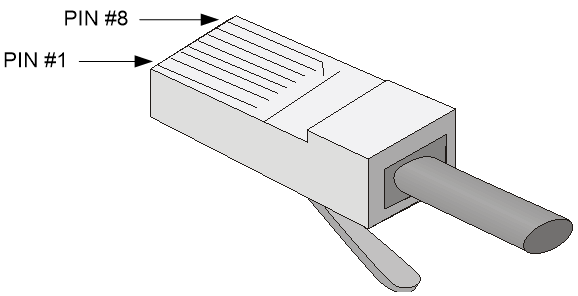

An AUX console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for connecting to the AUX port of the router, and DB-25 and DB-9 male connectors at the other end for connecting to the serial port of the modem.

Figure4-1 AUX cable

Connecting the AUX cable

1. Plug the DB-9 or DB-25 male connector at one end of the AUX cable into the serial port of the modem.

2. Plug the RJ-45 connector of the AUX cable into the AUX port of the router.

Figure4-2 Connecting the AUX port to a modem

Connecting an Ethernet cable

Overview

10/100 Mbps Ethernet uses category-5 twisted pair cables, while 1000 Mbps Ethernet uses category-5 enhanced or category-6 twisted pair cables. Twisted pair cables include straight-through cables and crossover cables.

Category-5 cables provide a transmission frequency of 100 MHz for voice and data transmission; they are mainly used in 100Base-T and 10Base-T networks. Category-5 cables are common Ethernet cables, which can also be used to transmit 1000 Mbps Ethernet data.

Category-5 enhanced cables feature low attenuation and crosstalk, providing higher attenuation to crosstalk ratio (ACR), less delay error and higher performance than category-5 cables. Category-5 enhanced cables are mainly used in 1000 Mbps Ethernet networks.

Category-6 cables provide a transmission frequency of 1 MHz to 250 MHz, and improve the performance on crosstalk and return loss. A fine better return loss performance is extremely important for new-generation full-duplex high-speed networks. Category-6 cables have sufficient power sum ACR (PS-ACR) when working at 200 MHz. They provide a bandwidth two times than that of category-5 enhanced cables, thus featuring a higher transmission performance. Therefore, category-6 cables are suitable for applications requiring a transmission speed of more than 1 Gbps.

The 10/100 Mbps Ethernet uses two pairs of cables, orange/white, orange, green/white and green cables, to transmit and receive data, while the 1000 Mbps Ethernet uses four pairs of cables to transmit and receive data.

An Ethernet twisted pair cable connects network devices through the RJ-45 connectors at the two ends. Figure4-3 shows the pinouts of an RJ-45 connector.

Figure4-3 RJ-45 connector pinout

EIA/TIA cabling specifications define two standards, 568A and 568B, for cable pinouts.

· Standard 568A—Pin 1: white/green stripe, pin 2: green steady, pin 3: white/orange stripe, pin 4: blue steady, pin 5: white/blue stripe, pin 6: orange steady, pin 7: white/brown stripe, pin 8: brown steady.

· Standard 568B—Pin 1: white/orange stripe, pin 2: orange steady, pin 3: white/green stripe, pin 4: blue steady, pin 5: white/blue stripe, pin 6: green steady, pin 7: white/brown stripe, pin 8: brown steady.

Ethernet twisted pair cables can be classified into straight-through and crossover cables based on their pinouts

For the pinouts of the twisted pair cables, see the following tables. (A and B represent the two ends of a cable, respectively.)

Table4-1 Straight-through cable pinouts

|

Pinout No. |

A |

B |

|

1 |

Orange/white |

Orange/white |

|

2 |

Orange |

Orange |

|

3 |

Green/white |

Green/white |

|

4 |

Blue |

Blue |

|

5 |

Blue/white |

Blue/white |

|

6 |

Green |

Green |

|

7 |

Brown/white |

Brown/white |

|

8 |

Brown |

Brown |

Table4-2 Crossover cable pinouts

|

Pinout No. |

A |

B |

|

1 |

Orange/white |

Green/white |

|

2 |

Orange |

Green |

|

3 |

Green/white |

Orange/white |

|

4 |

Blue |

Blue |

|

5 |

Blue/white |

Blue/white |

|

6 |

Green |

Orange |

|

7 |

Brown/white |

Brown/white |

|

8 |

Brown |

Brown |

|

|

NOTE: To avoid affecting communication quality, strictly follow the pinouts in the above tables when identifying or making the two types of Ethernet cables. |

Making an Ethernet cable

1. Cut the cable to a required length with the crimping pliers.

2. Strip off an appropriate length of the cable sheath. The length is typically that of the RJ-45 connector.

3. Untwist the pairs so that they can lay flat, and arrange the colored wires based on the wiring specifications.

4. Cut the top of the wires even with one another. Insert the wires into the RJ-45 end and make sure the wires extend to the front of the RJ-45 end and make good contact with the metal contacts in the RJ-45 end and in the correct order.

5. Crimp the RJ-45 connector with the crimping pliers until you hear a click.

6. Use a cable tester to verify the connectivity of the cable.

Connecting an Ethernet cable

1. Plug one end of an Ethernet twisted pair cable into the copper Ethernet port (RJ-45 port) to be connected on the router and the other end of the cable into the Ethernet port of the peer device. The 10/100/1000Base-T copper ports of the router support MDI/MDI-X auto-sensing. They are connected to the network through category-5 or above twisted pairs that are equipped with RJ-45 connectors.

2. Verify the status LED of the Ethernet ports. For more information about the LED status, see H3C SR6616 Routers Hardware Information and Specifications.

Connecting a fiber cable

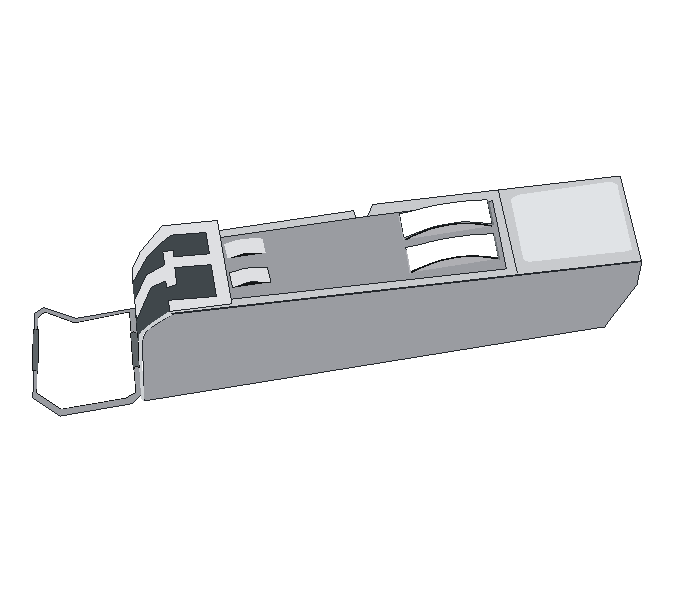

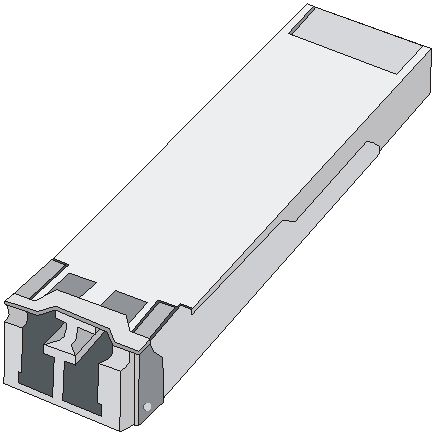

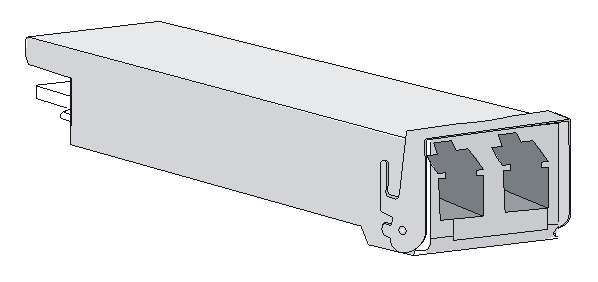

Transceiver modules

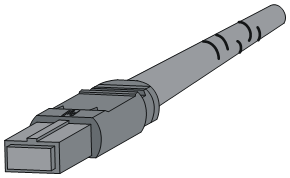

A transceiver module and a fiber cable with an LC or MPO connector are required for connecting a fiber port.

· SFP transceiver modules—Connecting 100/1000 Mbps Ethernet fiber ports and SFP ports on some HIMs.

· XFP transceiver modules—Connecting XFP ports on the HIM-1EXP.

· SFP+ transceiver modules—Connecting GE SFP+ ports on the MCP-X2.

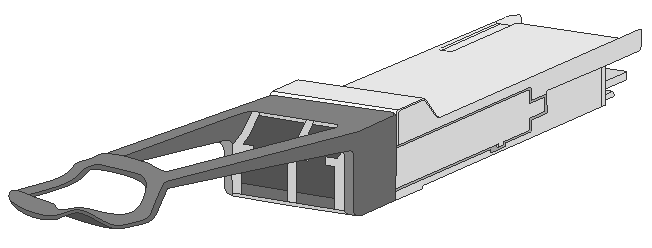

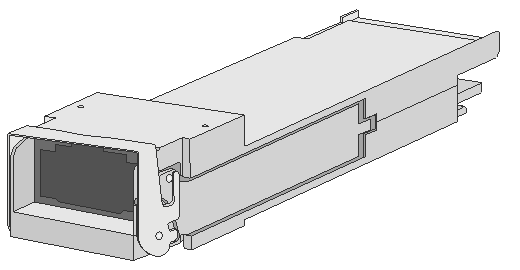

· QSFP+ transceiver modules—Connecting 40GE QSFP+ ports on the MIC-QP1L.

Figure4-4 SFP transceiver module

Figure4-5 XFP transceiver module

Figure4-6 SFP+ transceiver module

Figure4-7 QSFP+ transceiver module (LC port)

Figure4-8 QSFP+ transceiver module (MPO port)

Fiber cables

About fiber cables

You can use an optical fiber to connect a fiber Ethernet port or 10 Gbps Ethernet port. In addition, an optical fiber can connect these types of interface modules: HIM-4GBP/HIM-8GBP, HIM-CL1P/HIM-CL2P, HIM-CLS1P/HIM-CLS2P, HIM-MSP2P/HIM-MSP4P, HIM-PS1P, HIM-AL1P/HIM-AL2P, HIM-RS2P, HIM-1EXP, and MIC-QP1L.

Optical fibers feature low loss and long transmission distance.

Optical fibers can be classified into single-mode fibers and multi-mode fibers. A single-mode fiber carries only a single ray of light; a multi-mode fiber carries multiple modes of lights.

Table4-3 Characteristics of single-mode and multi-mode optical fibers

|

Item |

Single-mode fiber |

Multi-mode fiber |

|

Core |

Small core (10 micrometers or less) |

Larger core than single-mode fiber (50 micrometers, 62.5 micrometers or greater) |

|

Dispersion |

Less dispersion |

Allows greater dispersion and therefore, signal loss exists. |

|

Light source and transmission distance |

Users lasers as the light source often within campus backbones for distance of several thousand meters |

Uses LEDs as the light source often within LANs or distances of a couple hundred meters within a campus network |

Fiber connectors are indispensable passive components in an optical fiber communication system. They allow the removable connection between optical channels, which makes the optical system debugging and maintenance more convenient. There are multiple types of fiber connectors. Figure4-9 and Figure4-10 shows an LC connector and MPO connector, respectively

Figure4-10 MPO connector

Restrictions and guidelines

Some cards on the router provide dust plugs for the fiber ports (such as SFP ports). Before using such fiber ports, remove the dust plugs. Keep the dust plugs secure. When the fiber ports are not in use, install the dust plugs.

Fiber connectors are fitted with dust caps. Keep the dust caps secure when the fiber connectors are in use. Install dust caps when the fiber connectors are not in use to avoid damage to their end face. Replace the dust cap if it is loose or polluted.

Before connecting an optical fiber, use dust free paper and absolute alcohol to clean the end face of the two fiber connectors. You can brush the end faces only in one direction.

After a fiber is installed well, the bend radius must be not less than 10 cm (3.94 in).

To pass a fiber through a metallic board hole, make sure the hole has a sleek and fully filleted surface (the filleting radius must be not less than 2 mm, or 0.08 in). To pass a fiber through a metallic board hole or bend it along the acute side of mechanical parts, make sure the fiber wears jackets or cushions.

Insert and remove a plug with care. Never exert a fierce force to the fiber or plug; otherwise the plug might be damaged or the fiber might be broken. Never pull, press or extrude the fiber fiercely. For the allowed maximum tensile load and crush load, see Table4-4.

Table4-4 Allowed maximum tensile force and crush load

|

Period of force |

Tensile load (N) |

Crush load (N/mm) |

|

Short period |

150 |

500 |

|

Long term |

80 |

100 |

Connecting a fiber cable

|

WARNING! Do not stare into any fiber port when you connect an optical fiber. The laser light emitted from the fiber port might hurt your eyes. |

Connecting a fiber cable with an LC connector

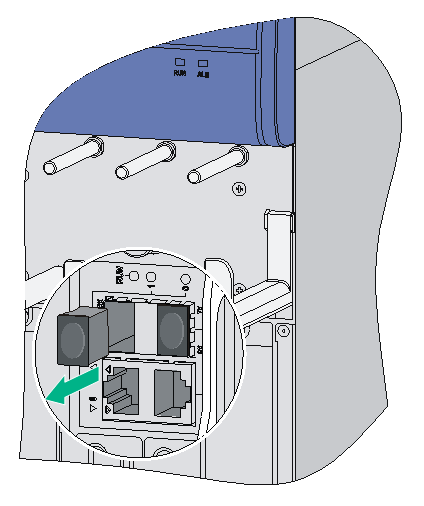

1. Remove the dust plug from a fiber port of the router.

Figure4-11 Removing the dust plug

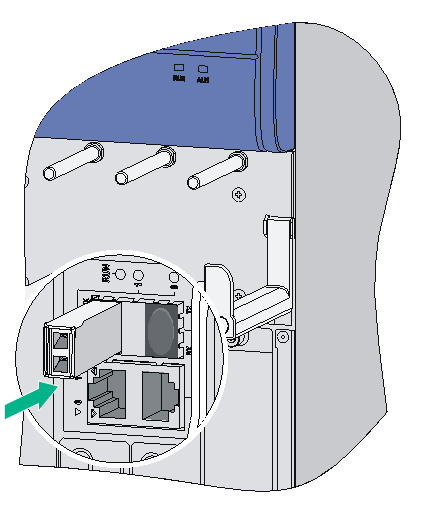

2. Install the transceiver module.

Figure4-12 Installing the transceiver module

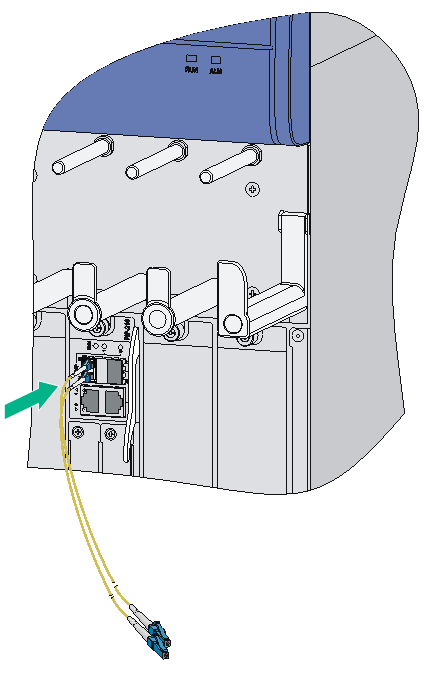

3. Identify the Rx and Tx ports. Plug the LC connector at one end of one fiber cable into the Rx port of the router and the LC connector at the other end into the Tx port of the peer device. Plug the LC connector at one end of another fiber cable into the Tx port of the router and the LC connector at the other end to the Rx port of the peer device.

Figure4-13 Installing the fiber connector

4. View the LINK LED after connection.

¡ If the LED is on, the optical fiber link is present.

¡ If the LED is off, no link is present. This might be because the TX and Rx port of the optical fiber are not connected correctly. In this case, connect the optical fiber again.

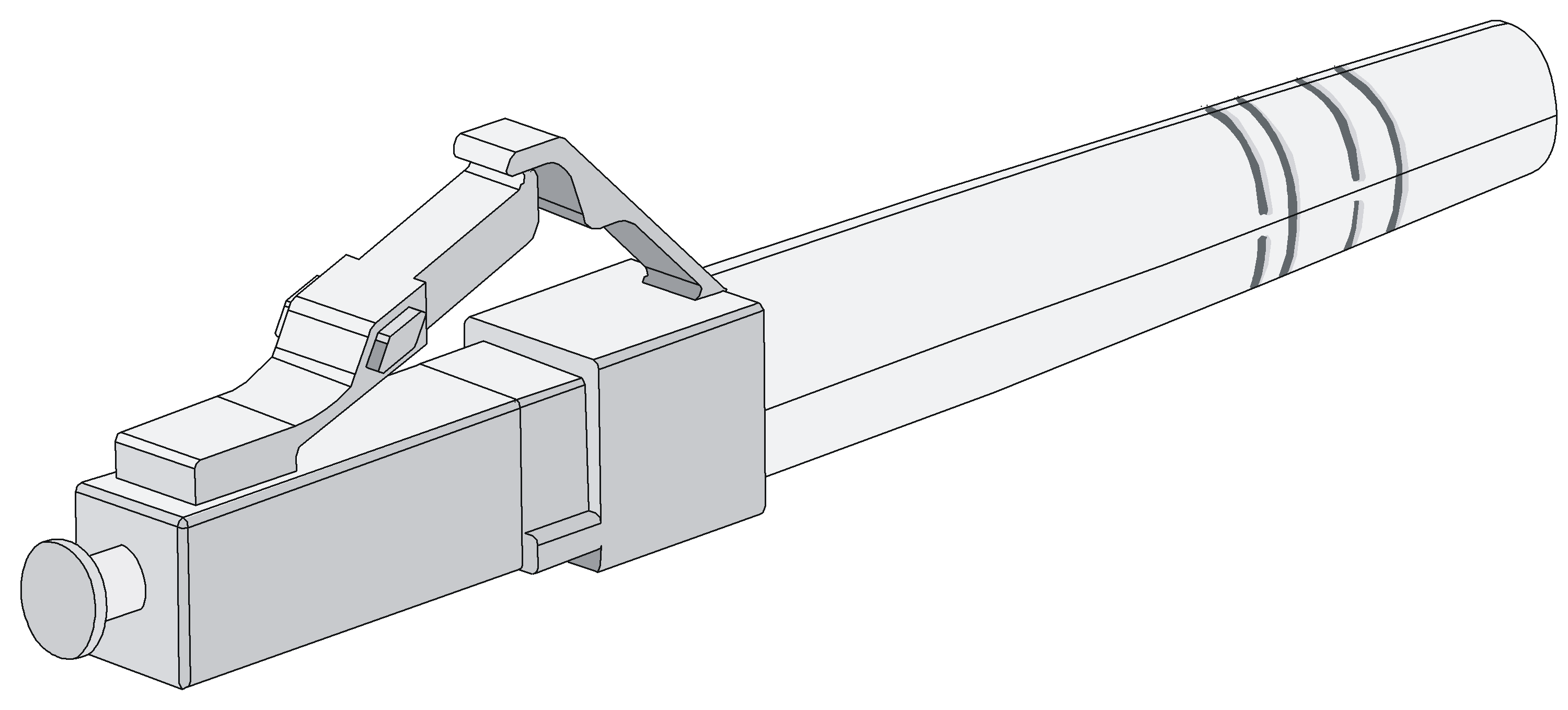

Connecting a fiber cable with an MPO connector

1. Wear an ESD wrist strap. Make sure the wrist strap makes good skin contact and is reliably grounded.

2. Remove the dust plug from the target fiber port.

For interface modules with dust plugs provided as accessories, install dust plugs for empty fiber ports in time.

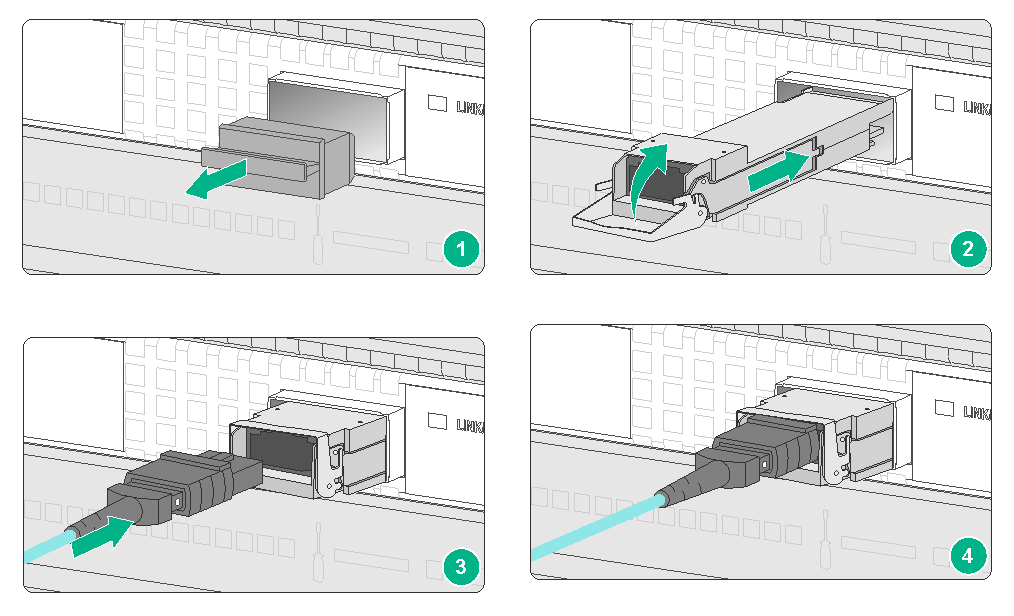

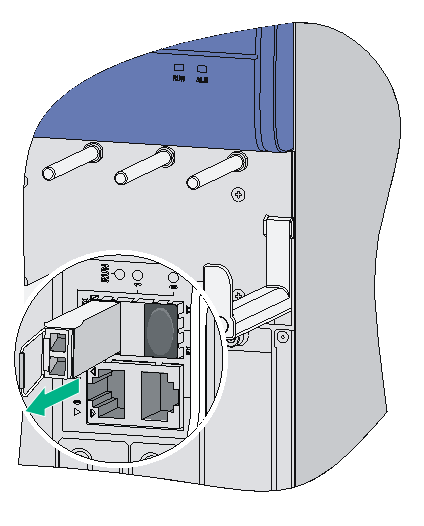

3. Pull the bail latch on the transceiver module upwards.

4. Take the transceiver module by its two sides and push the end without the bail latch gently into the port until it is firmly seated in the fiber port.

5. Remove the dust plug and dust cap from the transceiver module and fiber connector, respectively.

6. Orient the MPO fiber connector with the white dot on it facing right. Insert the connector horizontally into the transceiver module, and then push it into the transceiver module slightly until it clicks into the place, as shown in Figure4-14.

7. Use cable ties to bind the fiber cable every 150 mm (5.91 in).

8. Attach labels to the fiber cable as required.

Figure4-14 Installing a transceiver module and optical fiber (MPO connector)

Connecting an E1/T1 cable

|

CAUTION: When connecting the interface cable, pay attention to the mark on the interface to avoid wrong insertion, which might damage the interface module or even the router. |

As a best practice, install a lightning protector at the input end of the 8T1 cables to protect them against lightning strikes more efficiently when they are led outdoors.

E1/T1 cable overview

E1 cable

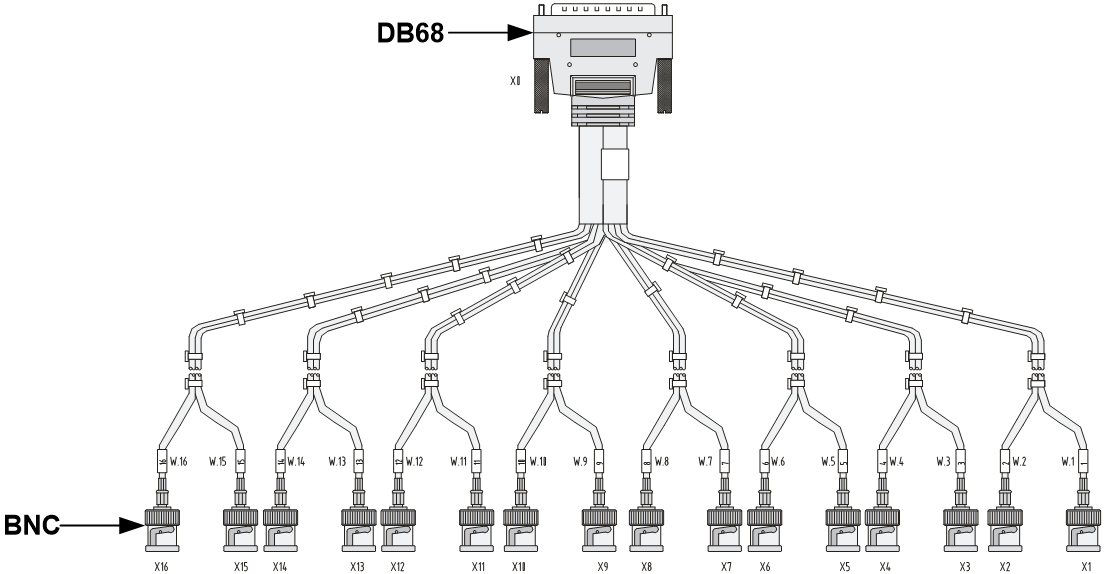

You can use an 8E1 interface cable to connect to MIM-8E1(75)/MIM-8E1(75)-F modules.

|

|

NOTE: The coaxial connector and 75-ohm E1 adapter cable are optional accessories, and must be purchased separately if needed. |

T1 cable

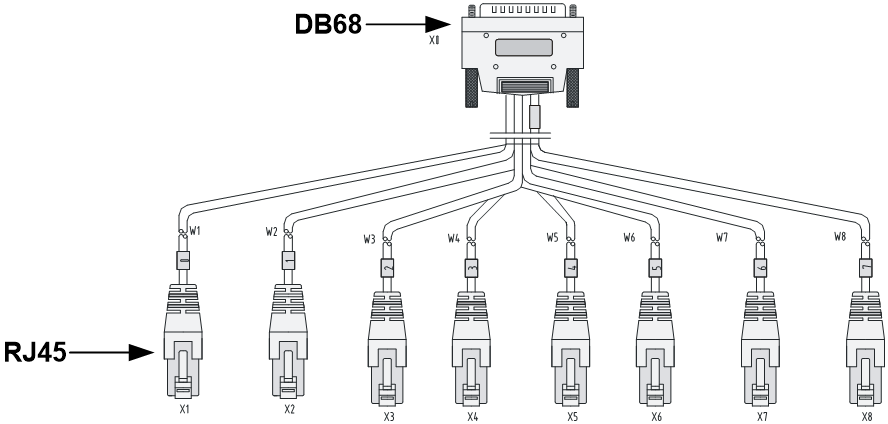

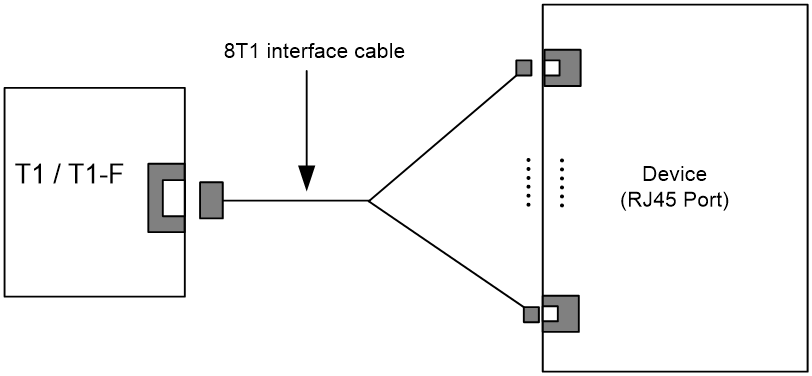

You can use an 8T1 interface cable to connect to MIM-8T1/MIM-8T1-F modules.

Figure4-16 8T1 splitter cable

Connecting an E1/T1 cable

Connecting an E1 cable (D15/D68 <----> BNC)

|

CAUTION: When connecting the interface cable, pay attention to the mark on the interface to avoid wrong insertion, which might damage the interface module or even the router. |

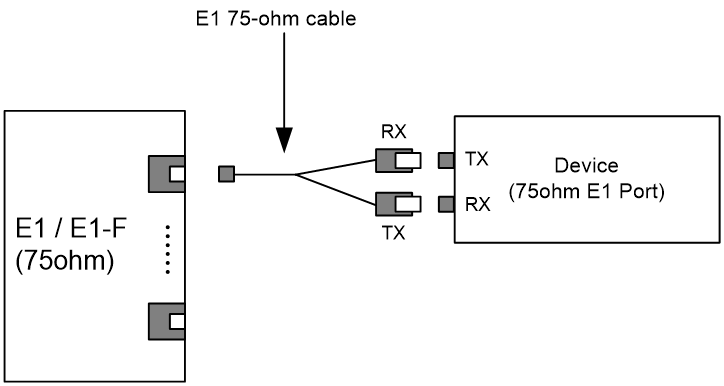

· If you do not need to extend the cable, you can directly connect the BNC connectors of the E1 75-ohm cable to the remote network device as follows.

a. Connect the D15/D68 connector of the E1 75-ohm cable to the D15/D68 interface of the interface module and fasten the bolts to secure the cable.

b. The other end of the cable provides one pair or multiple pairs of 75-ohm BNC connectors. Connect the TX connectors and the RX connectors on this end to the RX connectors and the TX connectors on the remote device respectively.

Figure4-17 Connecting an E1 75-ohm cable

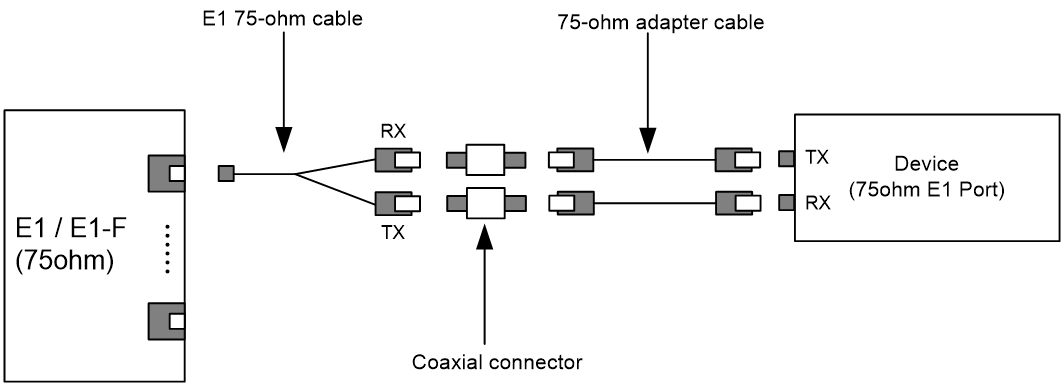

· If you want to extend the cable, connect each BNC connector of the E1 75-ohm cable to one end of a coaxial connector, and connect the remote device to the other end of the coaxial connector through an E1 75-ohm adapter cable.

Figure4-18 Connecting an E1 75-ohm cable

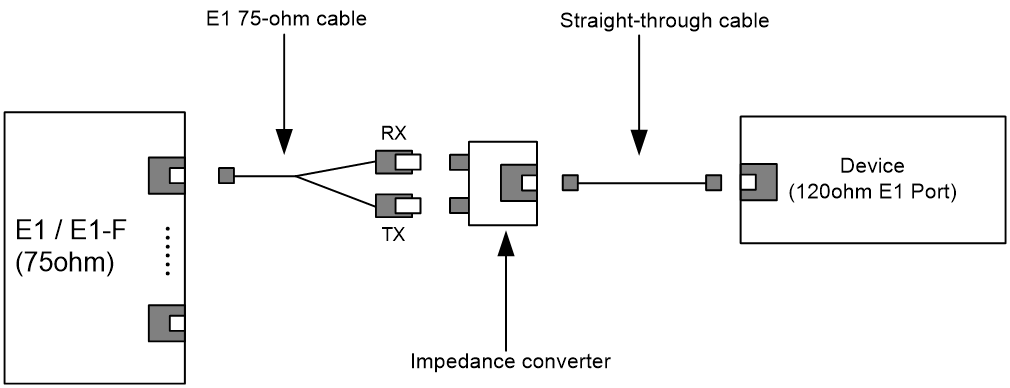

· If the impedance of the E1 interface on the remote device is 120 ohms, you must use an impedance converter to adapt the impedance.

Figure4-19 Connecting an impedance converter

Connecting a T1 cable

1. Connect the D68 connector of the 8-port T1 cable to the D68 interface on the interface module and fasten the bolts to secure the cable.

2. The other end of the cable provides eight RJ-45 connectors. Connect them to the RJ-45 interface on the remote device as needed.

Figure4-20 Connecting an 8T1 cable

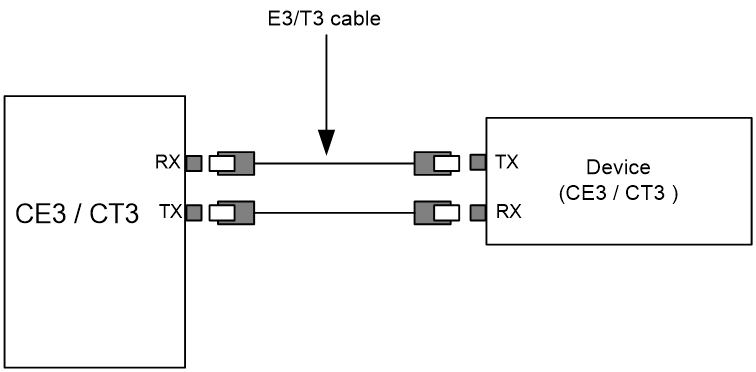

Connecting an E3/T3 cable

As a best practice, install a special lightning protector at the input end of the E3/T3 cables to protect them against lightning strikes more efficiently when they are routed outdoors.

E3/T3 cable overview

You can use an E3/T3 interface cable to connect the MIM-1CE3, MIM-1CT3, and MIM-1T3-V2 modules.

Connecting an E3/T3 cable

1. Connect the SMB connector of an E3/T3 cable to the Tx port on the interface module and the other end to the Rx port on the device to be connected.

2. Connect the SMB connector of another E3/T3 cable to the Rx port of interface module and the other end to the Tx port on the device to be connected

Figure4-22 Connecting an E3/T3 cable

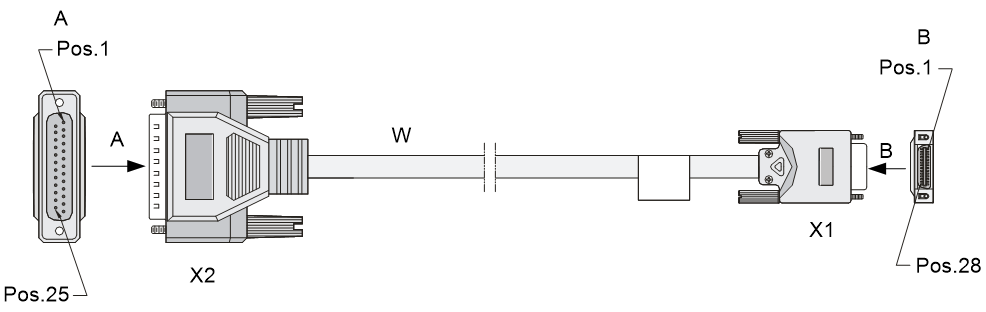

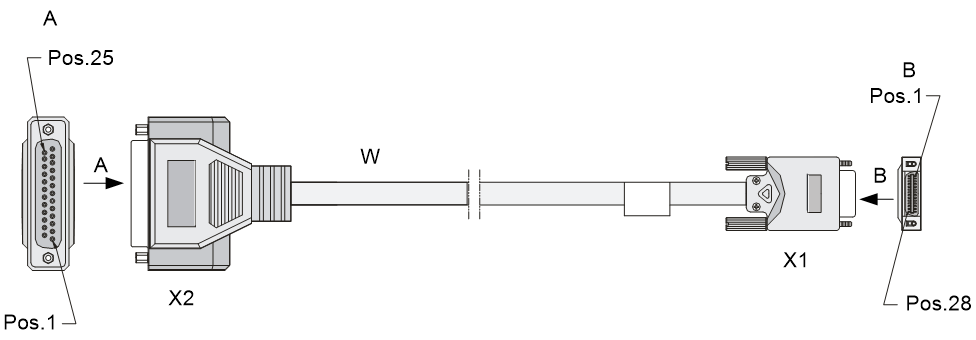

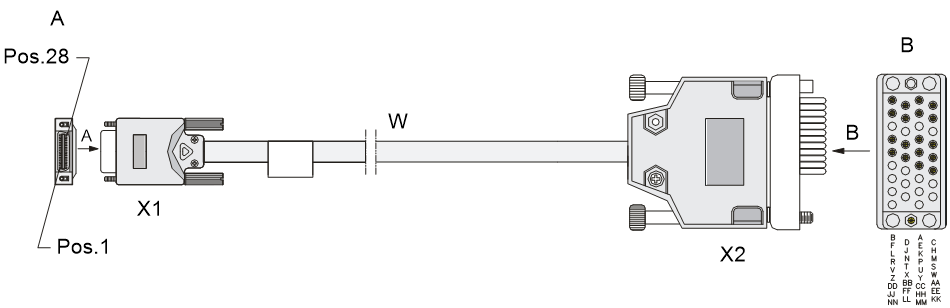

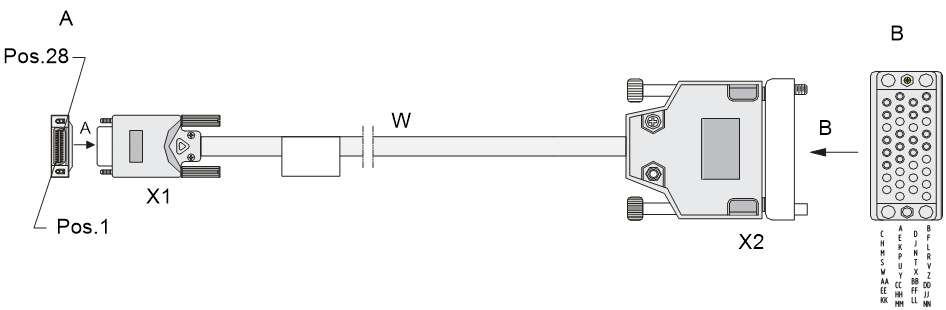

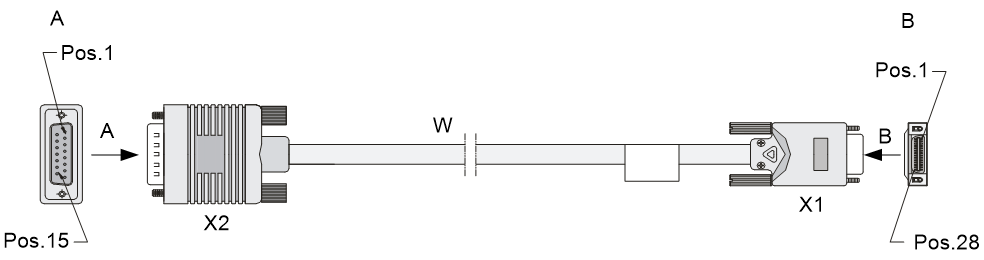

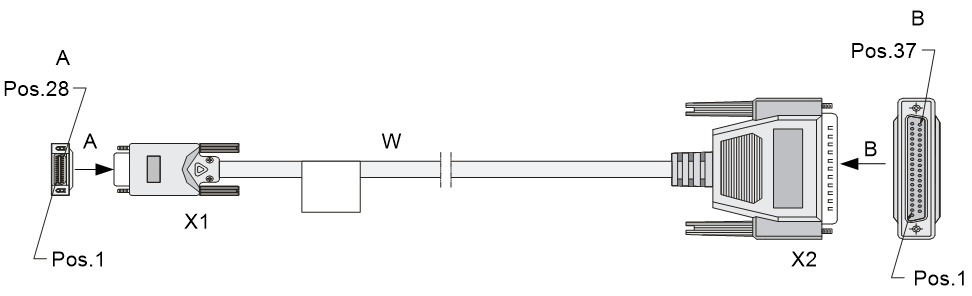

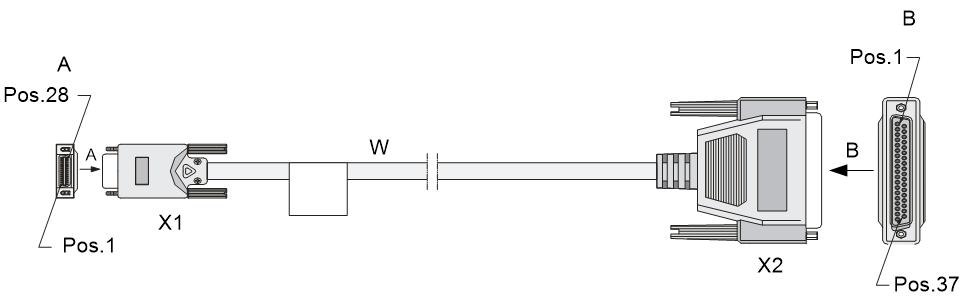

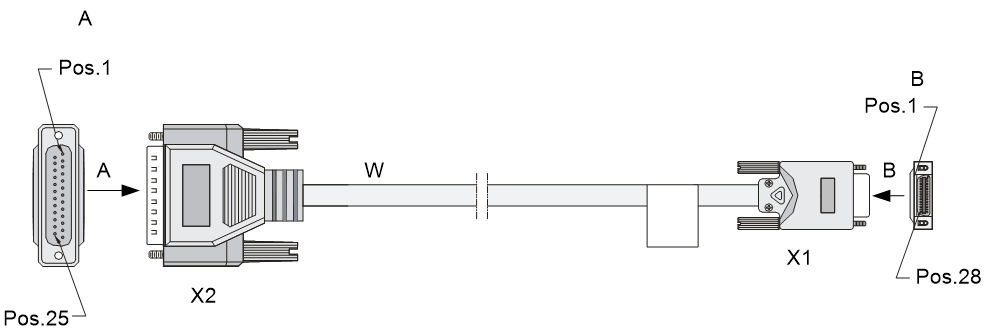

Connecting a serial port cable

Overview

You can use a serial port cable to connect to the MIM-2SAE/MIM-4SAE/MIM-8SAE module. Select a serial port cable according to the link type.

Figure4-23 V.24 DTE cable

Figure4-24 V.24 DCE cable

Figure4-25 V.35 DTE cable

Figure4-26 V.35 DCE cable

Figure4-27 X.21 DTE cable

Figure4-28 X.21 DCE cable

Figure4-29 RS449 DTE cable

Figure4-30 RS449 DCE cable

Figure4-31 RS530 DTE cable

Figure4-32 RS530 DCE cable

Connecting a serial port cable

1. Examine the port type of the peer device and choose the synchronous serial interface cable of correct type.

2. Plug the D28 end of the synchronous serial interface cable into the D28 interface of the SAE interface module.

3. If the WAN uses DDN line, connect the cable to the port of the CSU/DSU.

4. Identify the LINK LED on the SAE panel.

¡ If the LED is on, a link is present.

¡ If the LED is off, a fault has occurred on the link and signal is out of synchronization. In this case, examine the link.

5 Accessing the router

Login methods

The following logins methods are available for you to log in to the router:

· Logging in from the console port, which is the most common way to log in to a router and also the prerequisite for configuring other login methods. You can also use the USB console port to access the router.

· Logging in through Telnet or SSH.

· Logging in from the AUX port.

Logging in from the console port/USB console port

You can configure the router by connecting a configuration terminal to the console port or the USB console port on the router.

The first time you access the router, you can only log in to the router from the console port.

Connecting the console port by using a console cable

Console cables

As shown in Table5-1, two types of console cables can be used for connecting a configuration terminal to the console port on the router. No console cable is provided with the router. Purchase a console cable as required.

Table5-1 Console cables for connecting the console port

|

Console cable type |

Console cable view |

Router-side connector |

Configuration terminal-side connector |

Connection method |

|

DB9-to-RJ45 console cable |

DB-9 female connector |

RJ-45 |

||

|

USB-to-RJ45 console cable |

USB |

RJ-45 |

Connecting a DB9-to-RJ45 console cable

|

IMPORTANT: The serial ports on PCs do not support hot swapping. To connect a PC to an operating router, first connect the PC end. To disconnect a PC from an operating router, first disconnect the router end. |

To connect the router to a configuration terminal by using a console cable:

1. Select a configuration terminal, which can be a character terminal with an RS-232 serial port, or a PC.

If the PC does not have an RS-232 serial port but a USB port, use a USB to RS-232 adapter for the USB port and install the driver.

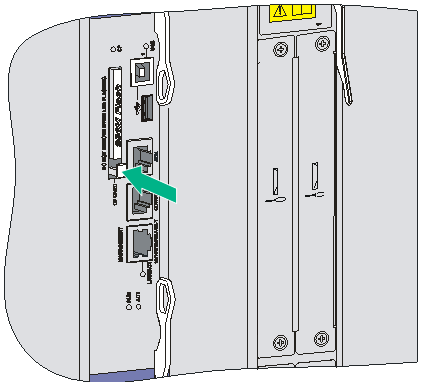

2. Plug the DB-9 female connector of the console cable into the serial port on the configuration terminal and the RJ-45 connector into the console port on the router.

Figure5-1 Connecting the console cable

Connecting a USB-to-RJ45 console cable

|

IMPORTANT: · To use a USB-to-RJ45 console cable to connect the router to a configuration terminal, first download and install the USB-to-RJ45 console driver on the configuration terminal, and then connect the USB-to-RJ45 console cable to the configuration terminal. To download the USB-to-RJ45 console driver, access the H3C official website or scan the QR code on the cable package. · If you have connected a USB-to-RJ45 console cable to the configuration terminal before installing the driver, remove and reconnect the USB-to-RJ45 console cable to the configuration terminal after driver installation. |

The following installs the driver on the Windows system. To install the driver on other operating systems, see the installation guide in the driver compression package named by using the corresponding operating system.

To connect the router to a configuration terminal by using a USB-to-RJ45 console cable:

1. Click the following link, or copy it to the address bar on your browser and download the USB-to-RJ45 console driver.

http://www.h3c.com/en/home/USB_to_RJ45_Console/

2. View the TXT file Read me in the Windows folder to check whether the Windows system of the configuration terminal supports the driver.

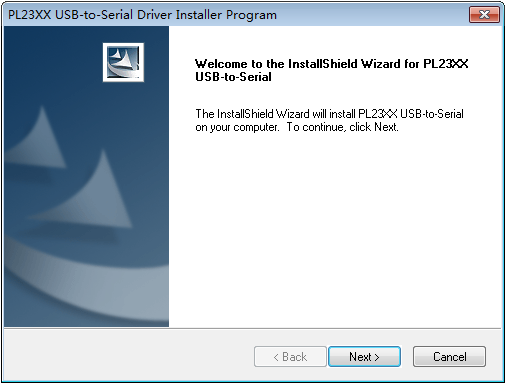

3. If the Windows system supports the driver, install PL23XX-M_LogoDriver_Setup_v200_20190815.exe.

4. Click Next on the welcome page of the driver installation wizard.

Figure5-2 Driver installation wizard

5. Click Finish after the drive installation is completed.

Figure5-3 Finishing the driver installation

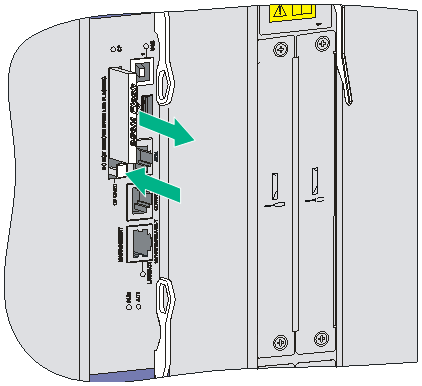

6. Connect the standard USB connector of the cable to the USB port of the configuration terminal.

7. Connect the RJ-45 connector of the cable to the console port of the router.

Connecting the USB console port by using a USB cable

|

IMPORTANT: After using a USB console cable to connect the router to a configuration terminal, you must download and install the USB console driver program from http://www.h3c.com/ before configuring the device. |

To use a USB console cable to connect the router to a configuration terminal:

1. Click the following link, or copy it to the address bar of the browser to log in to the download page of the USB console driver, and download the driver.

https://www.h3c.com/cn/Home/QR/USBControl.htm

2. Run Installer to pre-install the driver. A message that indicates successful driver pre-installation will pop up when the preinstallation is complete.

3. Connect the standard USB port of the USB cable to the configuration terminal.

4. Connect the mini USB port at the other end of the USB cable to the USB console port on the router. Then, the system will install the driver automatically.

Setting terminal parameters

To access the router from the console port, you must run a terminal emulator program, TeraTermPro or PuTTY, on the configuration terminal. For information about using a terminal emulator program, see the program's user guide.

The following are the required terminal settings:

· Baud rate—9600.

· Data bits—8.

· Stop bits—1.

· Parity—none.

· Flow control—none.

Powering on the router

Checking before power-on

Before powering on the router, verify the following items:

· The power cord and grounding cable are correctly connected.

· The power source voltage meets the requirement of the router.

· The console cable is correctly connected; the terminal or PC used for configuration has started, and the configuration parameters have been set.

· If a CF card is used, verify that the CF card is in position.

Checking after power-on

After powering on the router, check the following items:

· The LEDs on the front panel of the MPU are normal. For the LED description, see H3C SR6616 Routers Hardware Information and Specifications.

· The fans operate correctly, and you can hear fan rotating.

· The configuration terminal displays information normally. You can see the startup window on the local configuration terminal. For more information, see "Displaying boot information."

· After the power-on self-test (POST), the system prompts you to press Enter. When the command line prompt appears, the router is ready to configure.

Displaying boot information

After power-on, the router initializes its memory, and then runs the extended BootWare. The following information appears on the terminal screen:

System start booting...

Press Ctrl+D to access BASIC-BOOTWARE MENU

Press Ctrl+T to start memory test

Booting Normal Extend BootWare....

****************************************************************************

* *

* H3C SR66 BootWare, Version 7.1.064 *

* *

****************************************************************************

Copyright (c) 2004-2017 New H3C Technologies Co., Ltd.

Compiled Date : Apr 6 2017

CPU Type : MPC8548E

CPU L1 Cache : 32KB

CPU Clock Speed : 1000MHz

Memory Type : DDR2 SDRAM

Memory Size : 1024MB

Memory Speed : 400MHz

BootWare Size : 1024KB

Flash Size : 4MB

cfa0 Size : 495MB

NVRAM Size : 128KB

BASIC CPLD Version : 134.0

EXTEND CPLD Version : 133.0

PCB Version : Ver.C

BootWare Validating...

Press Ctrl+B to enter extended boot menu...

|

|

NOTE: · If the router is configured with two RPE-X1 MPUs in both slot 4 and slot 5, the router boots by using the RPE-X1 MPU in slot 4 by default. · If the router is configured with two RSE-X1 MPUs in both slot 5 and slot 6, the router boots by using the RSE-X1 MPU in slot 5 by default. |

Starting to get the main application file--cfa0:/main.bin!..................

......................................................

The main application file is self-decompressing

..........................................................................

..........................................................................

.......

.......

Done!

System is starting.....

Starting application at 0x00010000 ...

Mainboard 0 is master.

User interface con0 is available.

Press ENTER to get started.

Press Enter, and the following prompt appears:

<H3C>

You can now configure the router.

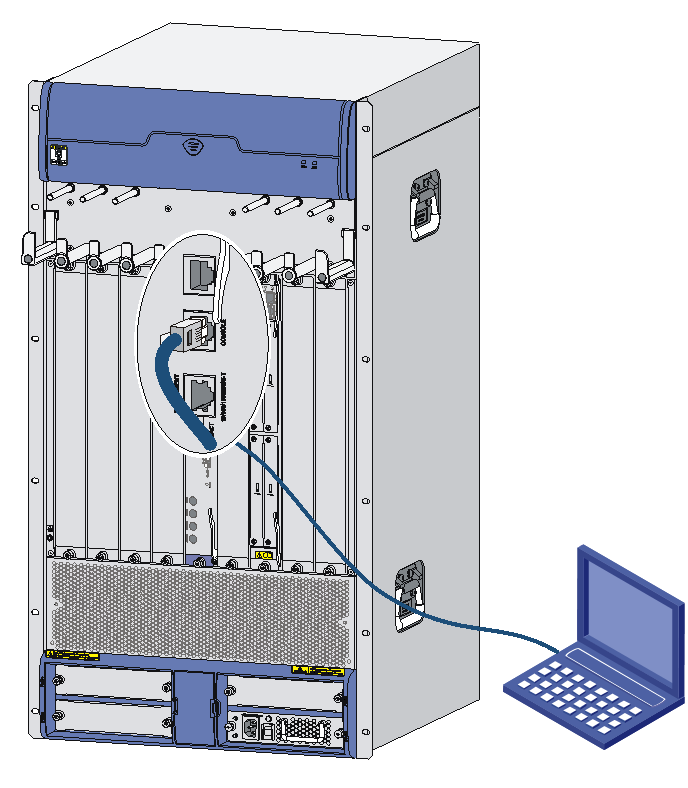

Logging in to the router through Telnet

1. After powering on the router, log in to the router through the console port. Enable the Telnet function on the router and set user privileges.

2. Connect the PC to the management Ethernet interface on the router and specify an IP address for the interface.

3. Specify an IP address for the PC, make sure the PC and the interface are in the same network segment.

For more information about how to log in to the router through Telnet, see H3C SR6600/SR6600-X Routers Configuration Guides.

Configuring basic settings

|

Step |

Command |

Remarks |

|

1. Set the current time and date. |

clock datetime time date |

Optional. Available in user view. |

|

1. Enter system view. |

system-view |

Required. Available in user view. |

|

2. Enter Ethernet interface view. |

interface interface-type interface-number |

N/A |

|

3. Specify an IP address for the interface. |

ip address ip-address { mask-length | mask } [ sub ] |

By default, no IP address is assigned to any interface. |

|

4. Return to system view. |

quit |

Available in any view. |

|

5. Specify a static route. |

ip route-static dest-address { mask | mask-length } { next-hop-address | interface-type interface-number [ next-hop-address ] | vpn-instance d-vpn-instance-name next-hop-address } track track-entry-number [ preference preference-value ] [ tag tag-value ] [ description description-text ] |

Required. By default, the preference of a static route is 60, tag is 0, and no description is configured. Do not specify the permanent keyword together with the bfd or track keyword. |

|

6. Save the current configuration to the root directory of the storage media, and specify it as the boot file to be used at the next boot. |

save [ safely ] [ backup | main ] [ force ] |

Available in any view. |

|

7. Display the running configuration. |

display current-configuration |

Available in any view. |

6 Replacement procedures

The router uses a modular, all-pluggable design, and supports replacing hot swappable modules without interrupting the router operation.

Safety recommendations

1. Always wear an ESD wrist strap or ESD gloves when replacing the modules.

2. When working with a removable module, such as an MPU, RPE-X1/RPE-X3/RPE-X5/RPE-X5E carrier (used when you use an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU), FIP module, SAP module, switching fabric module, memory module, CF card, or HIM/MIM/MIC, follow these guidelines:

¡ Ensure good alignment with the slot to avoid damage to the module during installation or removal.

¡ Before removing a module, make sure the captive screws are completely loosened. Otherwise, the panel of the module might be deformed.

¡ Avoid touching any components on the PCB during observing or moving the module.

¡ Put the removed module on an antistatic workbench with the PCB side facing upward or place them in antistatic bags.

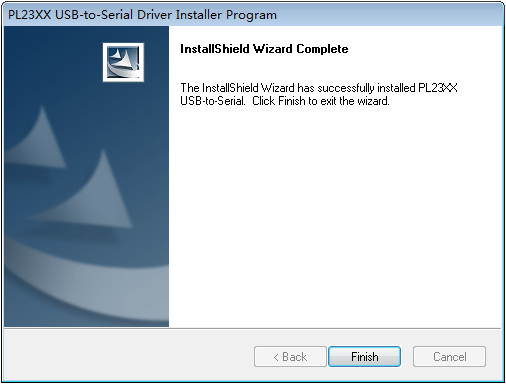

Replacing a power supply

The replacement procedure of an AC power supply is the same as a DC power supply. This section takes an AC power supply as an example.

To replace a power supply:

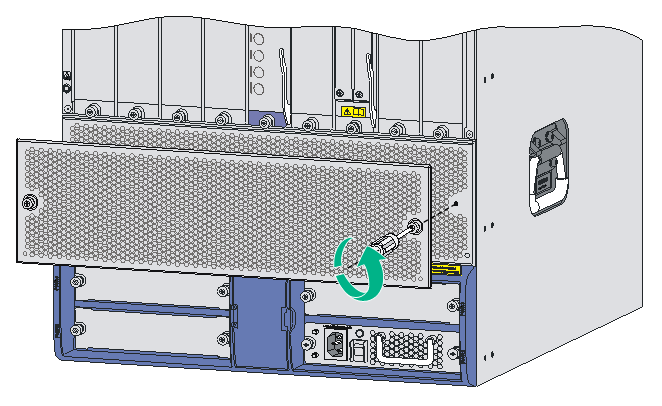

1. Loosen the captive screws of the power supply to be removed until all spring pressure is released.

2. Gently pull the power supply out of the slot along the slide rails.

Figure6-1 Pulling out the power supply

3. Put the removed power supply on an antistatic workbench or into an antistatic bag.

4. If you do not install a new power supply in the slot, install a filler panel. To install a power supply, see "Installing a power supply."

Replacing an MPU

Prerequisites

|

IMPORTANT: When a module is in unstable state, do not use the reboot command to trigger an active/standby switchover. You can use the display system stable state command to display the system stability and status information. |

1. If the router is configured with only one MPU, make sure all power sources to the router are turned off before replacing the MPU.

2. If the router is configured with two MPUs, make sure both MPUs operate correctly before replacing any MPU.

¡ As a best practice to replace the active MPU, execute the reboot command in the system view of the active MPU to trigger an active and standby switchover. For more information about the reboot command, see the command reference manual.

¡ To replace the standby MPU, you can remove it immediately.

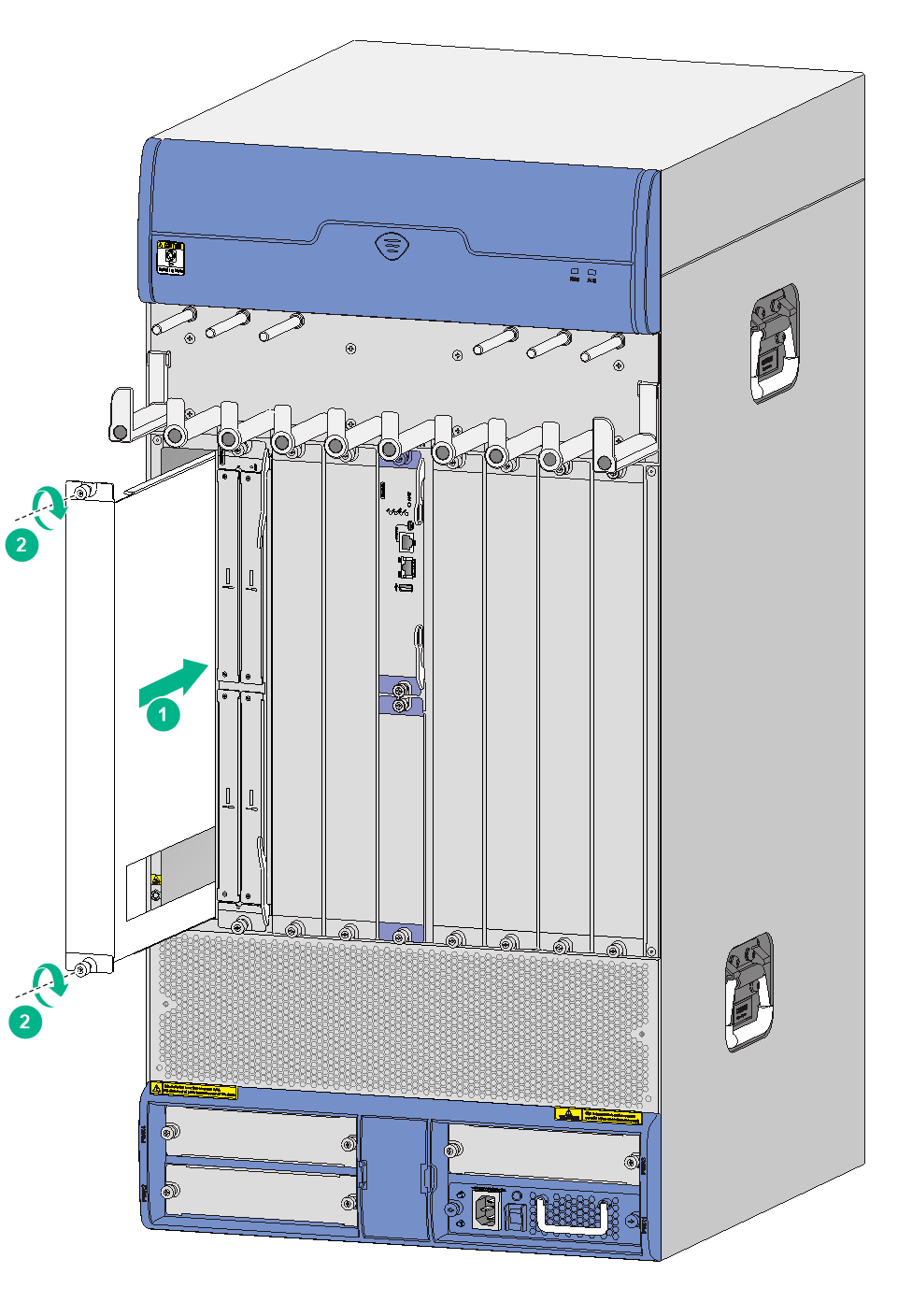

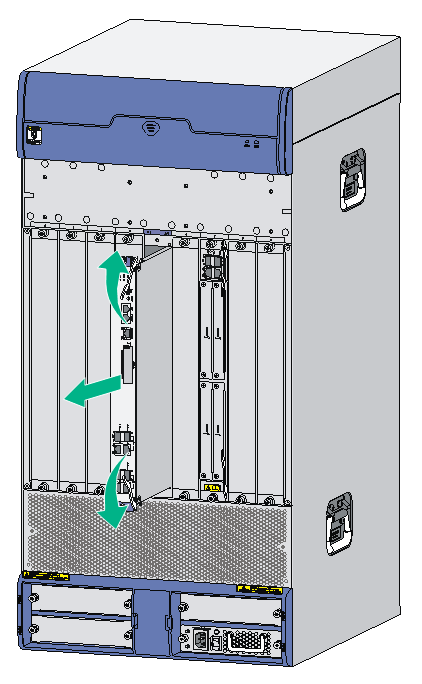

Replacing an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU

The replacement procedures for the RPE-X1, RPE-X3, RPE-X5, and RPE-X5E MPUs are the same. This example uses an RPE-X1.

To replace an RPE-X1 MPU:

1. Determine the MPU to be removed. This section takes the MPU in slot 4 as an example.

2. Loosen the captive screws of the MPU to be removed until all spring pressure is released.

3. Holding the ejector levers of the MPU with both hands, pull the ejector levers outward, and gently pull the MPU out of the slot along the slide rails.

Figure6-2 Pulling the RPE-X1 MPU out of the slot

4. Install a new RPE-X1 MPU. For more information, see "Installing an RPE-X1/RPE-X3/RPE-X5/RPE-X5E MPU."

Replacing an RSE-X1 MPU

1. Determine the MPU to be removed. This section takes the MPU in slot 5 as an example.

2. Loosen the captive screws of the MPU to be removed until all spring pressure is released.

3. Holding the ejector levers of the MPU with both hands, pull the ejector levers outward, and gently pull the MPU out of the slot along the slide rails.

Figure6-3 Pulling the RSE-X1 MPU out of the slot

4. If you do not install a new MPU in the slot, install a filler panel. To install a new MPU, see "Installing an RSE-X1 MPU."

Replacing an MCP

To replace an MCP, for example, MCP-X1:

1. Determine the MCP to be removed. This section takes the MCP in slot 5 as an example.

2. Loosen the captive screws on the MCP to be removed until all spring pressure is released.

3. Holding the ejector levers of the MCP with both hands, pull the ejector levers outward, and gently pull the MCP out of the slot along the slide rails.

Figure6-4 Pulling the MCP out of the slot

4. If you do not install a new MCP in the slot, install a filler panel. To install a new MCP, see "Installing an MCP MPU."

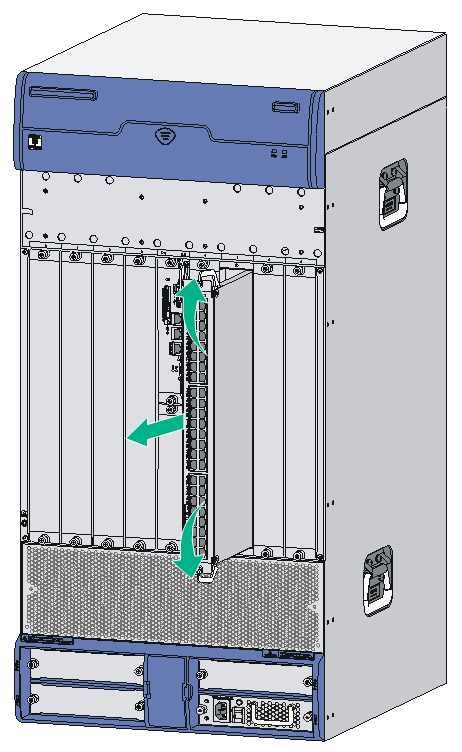

Replacing a FIP module

1. Determine the FIP module to be removed. This section takes the FIP module in slot 7 as an example.

2. Loosen the captive screws of the FIP module to be removed until all spring pressure is released.

3. Holding the ejector levers of the FIP module with both hands, pull the ejector levers outward, and gently pull the FIP module out of the slot along the slide rails.

Figure6-5 Pulling the FIP module out of the slot

4. If you do not install a new FIP module in the slot, install a filler panel. To install a new FIP module, see "Installing a FIP module."

Replacing an SSD drive

Before you remove an SSD drive, remove the service module from the router. For the removal procedure of service modules, see "Replacing a FIP module" or "Replacing a SAP/OAP/switching fabric module."

To remove an SSD drive:

1. Use a Phillips screwdriver to remove the fastening screws on the SSD drive.

2. Gently lift the SSD drive free from the connector and slightly pull the SSD drive out of the slot.

Keep the SSD drive secure.

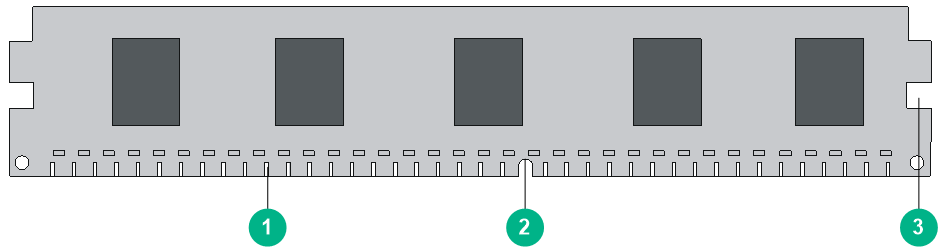

3. Install a new SSD drive. For the installation procedure, see "Installing an SSD drive."