Smart Power Plant Solution

I. Construction background

Power plants belong to the special process manufacturing industry that features complex production processes, high reliability requirements for equipment, and intensive assets. In the process of development, power plants face the problems that power generation units lack accurate online monitoring and evaluation, as well as preventive maintenance. Usually, one non-planned shutdown will cause a loss of millions of RMB. Therefore, it is the primary goal of power plants to realize economical operation of the units and high-efficiency energy conservation by using intelligent optimization technologies.

The Guiding Opinions on Vigorously Advancing the "Internet Plus" Action issued by the State Council explicitly points out the necessity of advancing intelligent energy production, constructing distributed energy networks, exploring new modes for energy consumption, and developing power grid based communication facilities and new businesses. Made in China 2025 points out that the digital, networked and intelligent manufacturing which is the deep integration of information technology and manufacturing technology shall be the main line, and intelligent manufacturing shall be the main target of the deep integration. In addition, with the active promotion of reform of electric power system and the marketization of the power sale side, profit and loss polarization, survival of the fittest, merging and reorganization may occur in the electric power industry in the future. Therefore, power plants need to shift thinking patterns, enhance lean management, lower cost and increase competitiveness in the market.

By deeply integrating information technologies such as cloud computing, big data, IoT, mobile application and AI with technologies and equipment in the power generation production process, transverse, longitudinal and end-to-end integration can be realized in the power plant. This increases the four key capabilities on overall perception, forecast and early warning, coordinative optimization, and scientific decision-making, and further improves the operating and management level of the power plant in a more sophisticated and dynamic way. A new trend on power generation and business mode innovation will be inevitable.

II. Overview

"Digital Brain Project" which uses the digital infrastructure, digital service capability platform, active security and O&M to constitute the four digital foundations of the "Intelligent Digital Platform", jointly creates intelligent application ecology with its partners to realize digital transformation for customers in all industries.

Based on its understanding and long-term practice in the power generation industry and by taking advantage of its "intelligent digital platform" (digital infrastructure, service capability platform, active security and unified operating and maintenance), H3C puts forward a total solution for intelligent power plants according to numerous ecologically intelligent applications in the power generation industry.

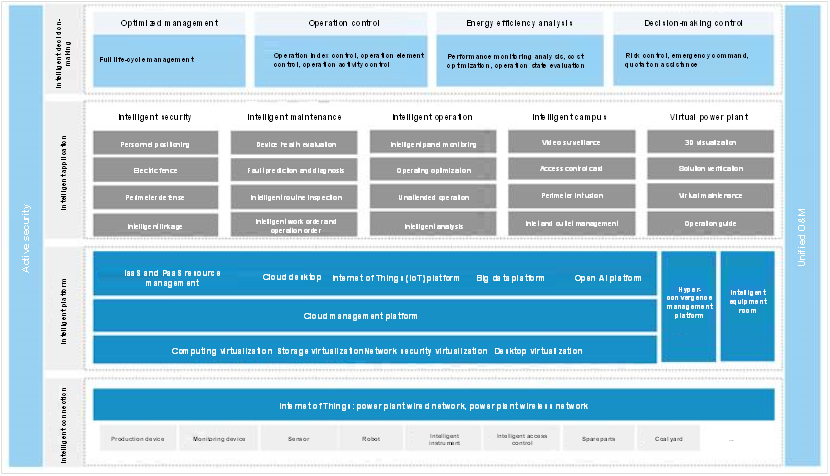

The total solution for intelligent power plants includes intelligent connection, intelligent platform, intelligent application, intelligent decision layer, as well as end-to-end active security and unified operating and maintenance.

Intelligent connection: Connecting the production equipment, monitoring equipment, sensors, patrol and inspection robots, intelligent instruments, intelligent access control, spare parts, and so on at the power plant to form an intelligent network through the IoT technology to realize intelligent connection among personnel, equipment and systems in an overall way.

Intelligent platform: It uses the virtual technology to realize resource pooling of IT infrastructure and transverse expansion of the resource pool. Unified management and intelligent scheduling of IT resources are realized through the cloud management platform. Based on the stable and reliable IaaS service capability, the infrastructure resources in the data center are effectively connected to help power plants shift their focus from cost to value during the informatization process. Based on PaaS service capabilities on Container, DevOps and microservice, quality resource platforms of cloud application are provided to power plants, shortening the service delivery cycle and helping power plants with cloudification transformation. Based on the IoT and big data platform, multi-source data collection, governance and analysis at power plants can be realized to further provide upper-layer intelligent applications with data support and to provide power plants with a decision-making basis on management optimization, operating control and energy efficiency analysis.

Intelligent application and decision-making: H3C, together with its ecological partners, conducts innovation in the fields of intelligent application and intelligent decision-making, including intelligent security, intelligent maintenance, intelligent operation, intelligent campus, management optimization, operation control, energy efficiency analysis, and so on to help power plants realize digital transformation.

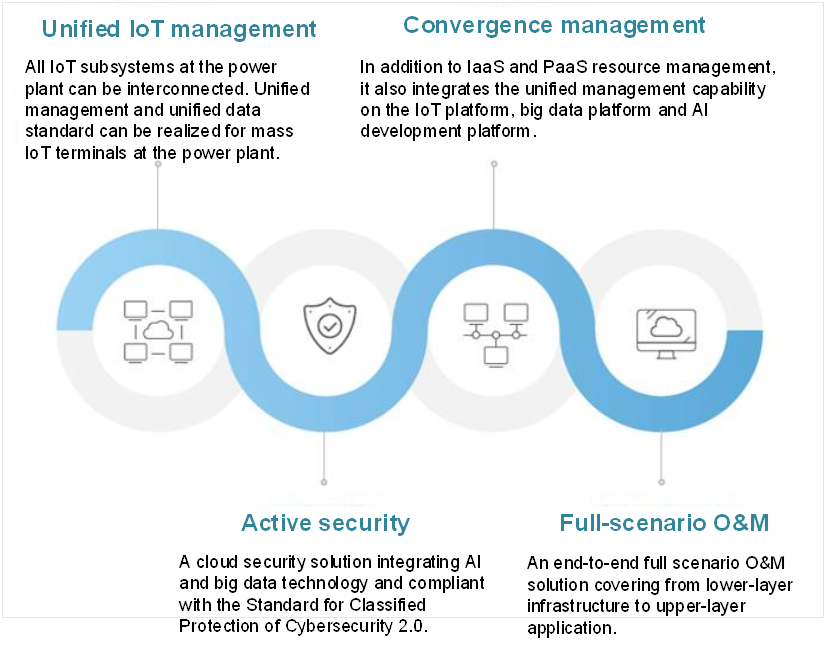

Active security: According to the security policy of "security zoning, network privatization, transverse isolation and longitudinal encryption" of power plants, and the requirements on information classified security protection, building AI and big data technology based active defense security strategies to increase prediction capability on information security.

Unified O&M: It includes establishment of a unified O&M platform to provide solutions for different types of equipment and application systems of a power plant, which may involve equipment, networks, platforms and service application systems. This could enhance the O&M management level.

III. Highlights

A case of excellent practice - construction of CHN Energy Suqian Intelligent Power Plant

Requirement analysis

As a pilot intelligent power plant under CHN Energy, Suqian Power Plant finds it difficult to meet the requirement of development by its original informatization construction level. Therefore, the power plant integrates information technologies such as cloud computing, big data, IoT, mobile application, AI and 3D visualization with industrial technologies and power plant management technologies in the production process in order to increase the intrinsic security level and risk prevention capability, obtain more standard operation management and better operation control, and lower operation costs. As a result, a novel and modern coal-fired power plant which is intelligent, secure, economical and environmentally friendly is successfully built.

Overview

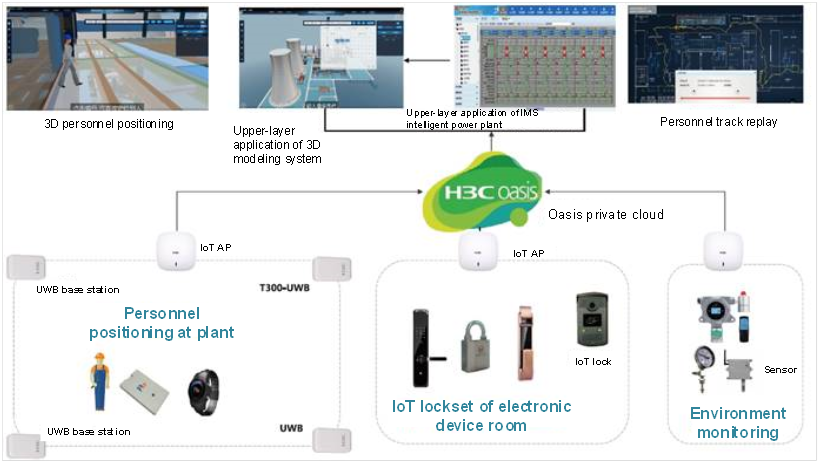

Using H3C UWB high-accuracy positioning technology to realize power plant personnel positioning, patrol and inspection tracking, equipment maintenance positioning, one-button alarm for emergency, and electric fences for important areas. Using H3C IoT platform, integrating all IoT subsystems of the power plant such as intelligent lockset, environment monitoring, personnel positioning, and so on, unifying IoT terminal data standards, and providing IoT equipment management, data modeling and data service for the power plant. In addition, transmitting the data of all IoT subsystems to the 3D modeling system and the IMS system through the API interface in order to provide intelligent application of the power plant with data support, and to help the power plant realize digital transformation with cooperation partners.

IV. Customer’s value

Unified IoT management: All IoT subsystems at the power plant can be interconnected. Unified management and unified data standard can be realized for mass IoT equipment at the power plant.

Personnel positioning: Using the UWB technology to realize high-accuracy positioning for power plant employees during the patrol and inspection process.

Electric fence: Set electric fences for dangerous areas at the power plant according to the electronic map. The electric fence can realize real-time alarm for intrusion so as to safeguard the safety of workers.

Intelligent patrol and inspection: Deeply integrating information technologies such as personnel positioning technology, full scenario wireless technology and 3D visualization technology with equipment patrol and inspection. In addition, using the equipment status assessment to conduct intelligent optimization and arrangement for patrol and inspection objects, patrol and inspection routes, special attention points and hazardous sources, and so on, in order to increase routine inspection efficiency and safety level.

Expert system: Sending back the operation pictures of workers in real time and relying on the backstage expert system to ensure the normalization and safety on operation protective measures at site.